Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Strip Mill Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Strip Mill Operator so you can tailor your answers to impress potential employers.

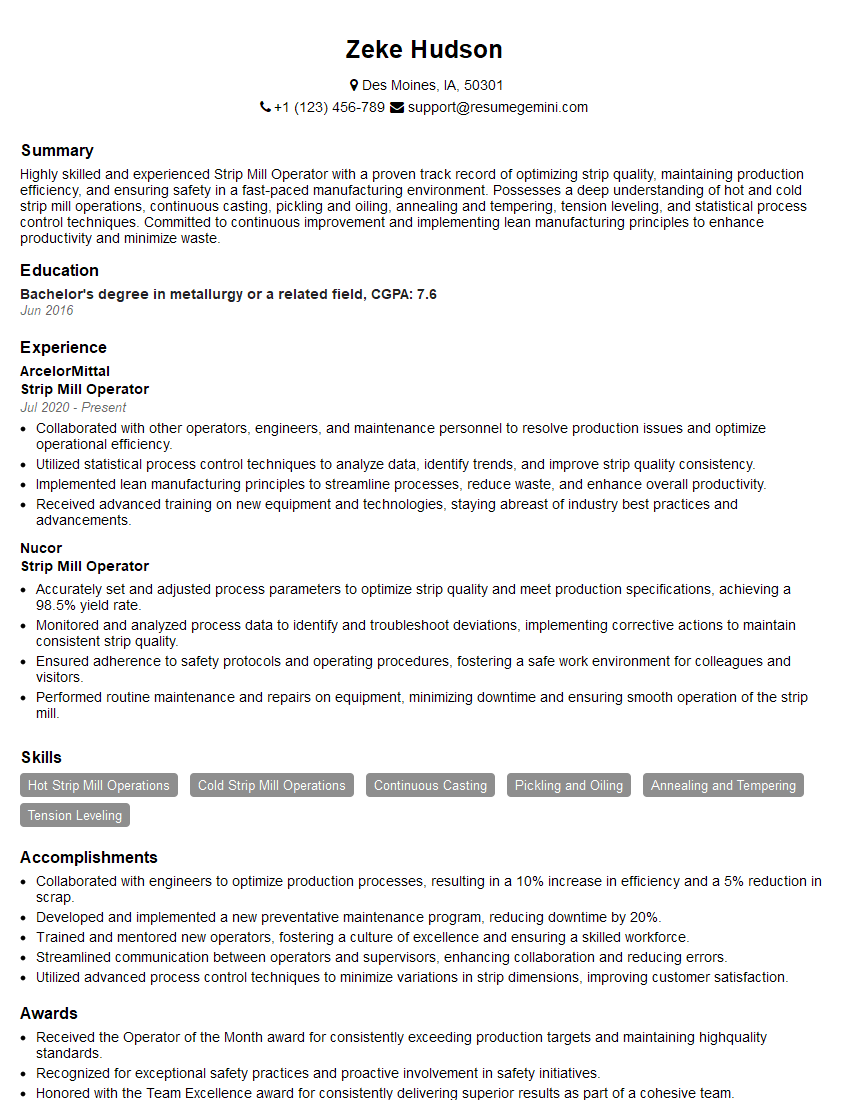

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Strip Mill Operator

1. Explain the process of hot rolling in a strip mill.

Hot rolling is a metalworking process in which a heated metal is passed through a series of rollers to reduce its thickness and increase its length. In a strip mill, hot rolling is used to produce flat-rolled products, such as sheet steel and plate steel. The process of hot rolling in a strip mill typically involves the following steps:

- The metal is heated to a high temperature, typically between 1,200 and 1,300 degrees Fahrenheit.

- The heated metal is passed through a series of rollers, which are arranged in a sequence of progressively decreasing diameters.

- As the metal passes through the rollers, it is compressed and elongated, resulting in a reduction in thickness and an increase in length.

- The rolled metal is then cooled and coiled.

2. What are the key process parameters that you monitor and control in the strip mill?

- Roll force

- Roll speed

- Strip tension

- Strip temperature

- Roll gap

Controlling these parameters is critical to producing high-quality strip products.

3. How do you ensure the quality of the strip products?

I ensure the quality of the strip products by:

- Monitoring the process parameters mentioned in the previous question.

- Inspecting the strip products for defects, such as cracks, surface imperfections, and dimensional inaccuracies.

- Making adjustments to the process parameters as needed to correct any quality issues.

- Working with other members of the production team to identify and resolve any quality problems.

4. What is the difference between a hot strip mill and a cold strip mill?

- Hot strip mills roll steel at high temperatures, typically between 1,200 and 1,300 degrees Fahrenheit.

- Cold strip mills roll steel at room temperature or slightly above.

- Hot strip mills produce thicker strip products, typically 0.060 inches or thicker.

- Cold strip mills produce thinner strip products, typically 0.059 inches or thinner.

- Hot strip mills are typically used to produce strip products for applications where strength and durability are important, such as in the automotive and construction industries.

- Cold strip mills are typically used to produce strip products for applications where precision and surface finish are important, such as in the appliance and electronics industries.

5. What are the challenges of working as a Strip Mill Operator?

- The work can be physically demanding, as it requires lifting heavy objects and working in a hot environment.

- The work can be repetitive and monotonous.

- The work can be dangerous, as it involves working with heavy machinery.

- The work can be stressful, as it is important to meet production targets and quality standards.

6. What are your strengths and weaknesses as a Strip Mill Operator?

My strengths as a Strip Mill Operator include:

- I am a highly skilled and experienced operator with a strong understanding of the strip mill process.

- I am able to quickly identify and resolve problems, and I am always looking for ways to improve the efficiency of the operation.

- I am a team player and I am always willing to help out my colleagues.

My weaknesses as a Strip Mill Operator include:

- I can be a bit impatient at times, and I sometimes have difficulty dealing with stress.

- I am not always the most organized person, and I sometimes have difficulty keeping up with all of the paperwork that is required for the job.

7. How do you stay up-to-date on the latest developments in the strip mill industry?

I stay up-to-date on the latest developments in the strip mill industry by:

- Reading trade publications and attending industry conferences.

- Talking to other strip mill operators and engineers.

- Participating in online forums and discussion groups.

8. What are your career goals?

My career goals are to:

- Continue to develop my skills and knowledge as a Strip Mill Operator.

- Move into a supervisory or management role in the strip mill industry.

- Eventually start my own strip mill business.

9. Why should we hire you?

You should hire me because I am a highly skilled and experienced Strip Mill Operator with a strong understanding of the strip mill process. I am able to quickly identify and resolve problems, and I am always looking for ways to improve the efficiency of the operation. I am a team player and I am always willing to help out my colleagues. I am also committed to staying up-to-date on the latest developments in the strip mill industry.

10. Do you have any questions for me?

I do not have any questions for you at this time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Strip Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Strip Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Strip Mill Operators play a pivotal role in the steel production process, ensuring the smooth and efficient operation of the strip mill. Their key responsibilities encompass a wide range of tasks including:

1. Equipment Operation

Operate and monitor the strip mill equipment, including the rolling stands, control systems, and auxiliary machinery, to produce steel strip to the required specifications.

2. Process Control

Monitor and adjust process parameters such as temperature, tension, and speed to ensure the production of high-quality steel strip within specified tolerances.

3. Quality Control

Conduct inspections and tests on the steel strip to ensure it meets the required quality standards and specifications.

4. Maintenance and Troubleshooting

Perform routine maintenance and repairs on the equipment to keep the mill operating smoothly and prevent breakdowns. Troubleshoot and resolve production issues to minimize downtime.

5. Safety and Compliance

Adhere to all safety regulations and procedures to ensure a safe and healthy work environment. Comply with environmental regulations and maintain a clean and organized work area.

Interview Tips

To effectively prepare for a Strip Mill Operator interview, it is crucial to highlight your technical skills, operational experience, and commitment to safety. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. Demonstrate your knowledge of their industry, production process, and safety protocols.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in operating and maintaining strip mill equipment. Quantify your accomplishments and provide specific examples of your contributions to previous operations.

3. Showcase Problem-Solving Abilities

Discuss your experience in troubleshooting and resolving production issues. Explain how you have used your analytical skills to identify and rectify complex problems.

4. Emphasize Safety and Compliance

Stress your commitment to safety and highlight your knowledge of relevant regulations and procedures. Describe your proactive approach to maintaining a safe work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Strip Mill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.