Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stripping Cutter and Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

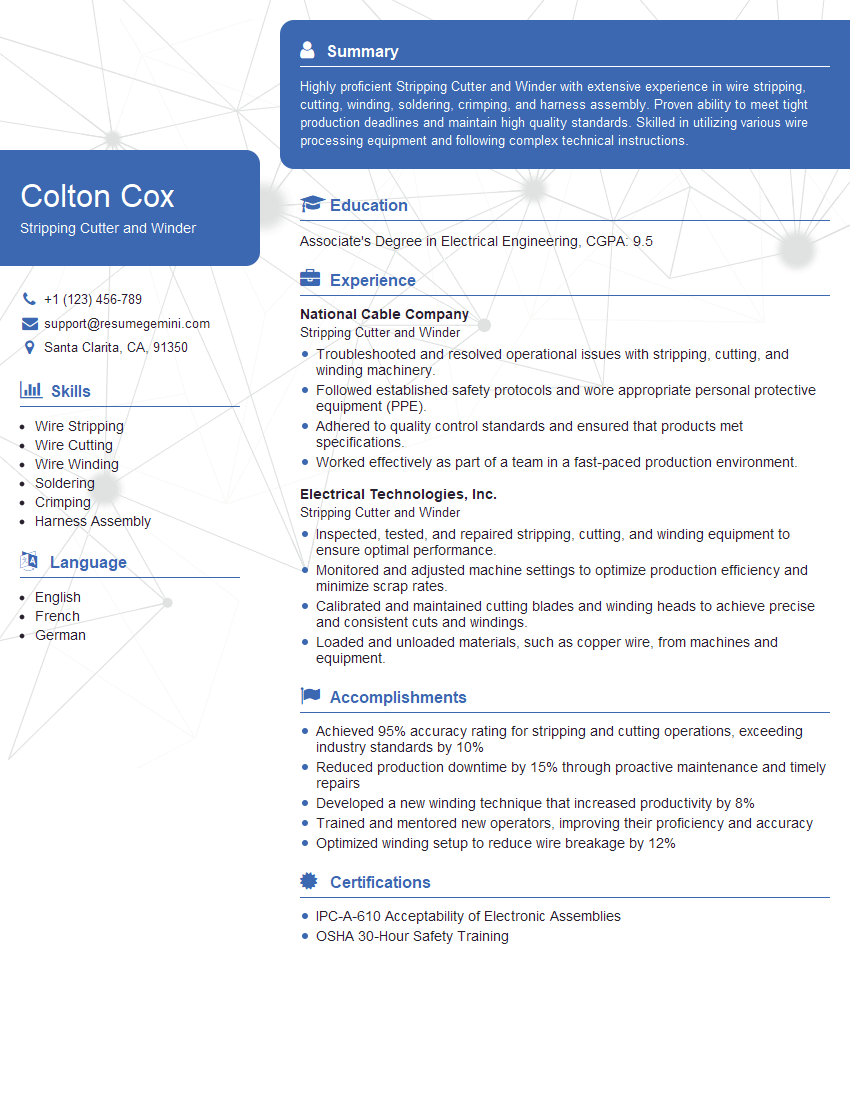

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stripping Cutter and Winder

1. Describe the process of setting up and operating a stripping cutter and winder machine?

Sample Answer

- Install the appropriate cutting blade and winding head on the machine.

- Calibrate the machine according to the desired cutting length and winding tension.

- Load the wire or cable onto the spool and secure it.

- Thread the wire or cable through the cutting blade and winding head.

- Start the machine and adjust the speed and tension as needed.

- Monitor the machine’s operation and make any necessary adjustments.

- Remove the finished product from the machine.

2. What are the different types of cutting blades and winding heads available for stripping cutter and winder machines, and when should each type be used?

Types of Cutting Blades

- Straight blades: Used for cutting straight cuts in wire or cable.

- Diagonal blades: Used for cutting angled cuts in wire or cable.

- Notched blades: Used for cutting notches or grooves in wire or cable.

Types of Winding Heads

- Single head: Used for winding wire or cable onto a single spool.

- Multiple head: Used for winding wire or cable onto multiple spools simultaneously.

- Traverse head: Used for winding wire or cable in a specific pattern, such as a helical or spiral pattern.

Sample Answer

- Straight blades are used for general-purpose cutting applications.

- Diagonal blades are used for cutting angled cuts, such as when preparing wire for splicing.

- Notched blades are used for cutting notches or grooves in wire or cable, such as when creating terminals.

- Single heads are used for small-scale winding applications.

- Multiple heads are used for high-volume winding applications.

- Traverse heads are used for winding wire or cable in specific patterns.

3. How do you troubleshoot common problems with stripping cutter and winder machines, such as uneven winding, wire breakage, or machine jams?

Sample Answer

- Uneven winding: This can be caused by a variety of factors, such as incorrect tension settings, worn cutting blades, or a faulty winding head. Adjust the tension settings, replace the cutting blades, or repair the winding head as needed.

- Wire breakage: This can be caused by a variety of factors, such as using the wrong type of cutting blade, applying too much tension, or using a dull cutting blade. Select the correct type of cutting blade, adjust the tension settings, or replace the cutting blade as needed.

- Machine jams: This can be caused by a variety of factors, such as wire or cable getting tangled, a build-up of debris, or a mechanical failure. Clear the tangle, remove the debris, or repair the mechanical failure as needed.

4. What safety precautions should be taken when operating a stripping cutter and winder machine?

Sample Answer

- Wear appropriate safety gear, such as safety glasses, gloves, and hearing protection.

- Keep the work area clean and free of debris.

- Inspect the machine before each use and make sure it is in good working order.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Follow the manufacturer’s instructions for operating the machine.

5. How do you maintain a stripping cutter and winder machine to ensure optimal performance and longevity?

Sample Answer

- Clean the machine regularly to remove any debris or build-up.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the cutting blades and winding head regularly and replace them as needed.

- Calibrate the machine regularly to ensure it is cutting and winding accurately.

- Follow the manufacturer’s instructions for maintenance and troubleshooting.

6. What is the difference between a stripping cutter and a wire stripper?

Sample Answer

- A stripping cutter is a machine that cuts and strips the insulation from wire or cable.

- A wire stripper is a tool that is used to remove the insulation from wire or cable by hand.

7. What are the benefits of using a stripping cutter and winder machine over hand-stripping and winding wire or cable?

Sample Answer

- Increased speed and efficiency.

- Improved accuracy and consistency.

- Reduced risk of injury.

8. What are the different types of wire and cable that can be processed using a stripping cutter and winder machine?

Sample Answer

- Copper wire

- Aluminum wire

- Coaxial cable

- Twisted-pair cable

9. What is the maximum capacity of wire or cable that can be processed using the stripping cutter and winder machine?

Sample Answer

- The maximum capacity will vary depending on the specific machine.

- It is important to consult the manufacturer’s specifications for the specific machine you are using.

10. What are the different types of applications that can be performed using a stripping cutter and winder machine?

Sample Answer

- Preparing wire or cable for splicing

- Creating terminals

- Winding wire or cable onto spools

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stripping Cutter and Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stripping Cutter and Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Stripping Cutter and Winder is a skilled professional responsible for the operation, maintenance, and troubleshooting of stripping and winding machinery in a manufacturing setting.

1. Strip and Cut Material

Prepare and cut metal or other materials to specified dimensions and shapes.

- Load and align the material on the cutting machine.

- Adjust and calibrate the cutting equipment according to the specified specifications.

2. Operate Winding Equipment

Operate winding machines to spool and wrap cut materials onto reels or spools.

- Set up and run winding machines, ensuring proper tension and alignment.

- Monitor winding operations and make adjustments as needed to achieve optimal results.

3. Maintain and Repair Equipment

Perform ongoing maintenance and troubleshooting of stripping and winding equipment.

- Identify and resolve mechanical, electrical, and hydraulic malfunctions promptly.

- Inspect and clean equipment regularly to ensure optimal performance.

4. Ensure Product Quality

Inspect stripped and wound materials to ensure they meet quality standards.

- Check for defects, such as cuts, tears, or scratches.

- Follow established quality control procedures and report any discrepancies.

Interview Tips

To effectively prepare for an interview for the Stripping Cutter and Winder position, consider the following tips:

1. Research the Company and Position

Gather information about the company, its products or services, and the specific responsibilities of the Stripping Cutter and Winder role.

- Visit the company’s website.

- Read trade publications and industry news.

- Connect with employees on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your background in material handling, machine operation, and quality control.

- Quantify your accomplishments with specific examples.

- Use action verbs to describe your skills.

- Examples: “Developed and implemented a preventive maintenance program that reduced machine downtime by 20%” or “Trained a team of operators on proper winding techniques, resulting in a 15% increase in production efficiency.”

3. Prepare for Common Interview Questions

Anticipate typical interview questions and prepare thoughtful responses.

- Tell me about your experience in operating stripping and winding machinery.

- How do you ensure the quality of the materials you produce?

- Describe a time when you had to troubleshoot and repair a malfunctioning machine.

- What is your understanding of preventive maintenance?

4. Practice Your Interview Skills

Rehearse your answers to common interview questions and ask a friend or family member to conduct a mock interview.

- Practice your delivery and ensure you maintain eye contact.

- Dress professionally and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stripping Cutter and Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!