Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stripping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

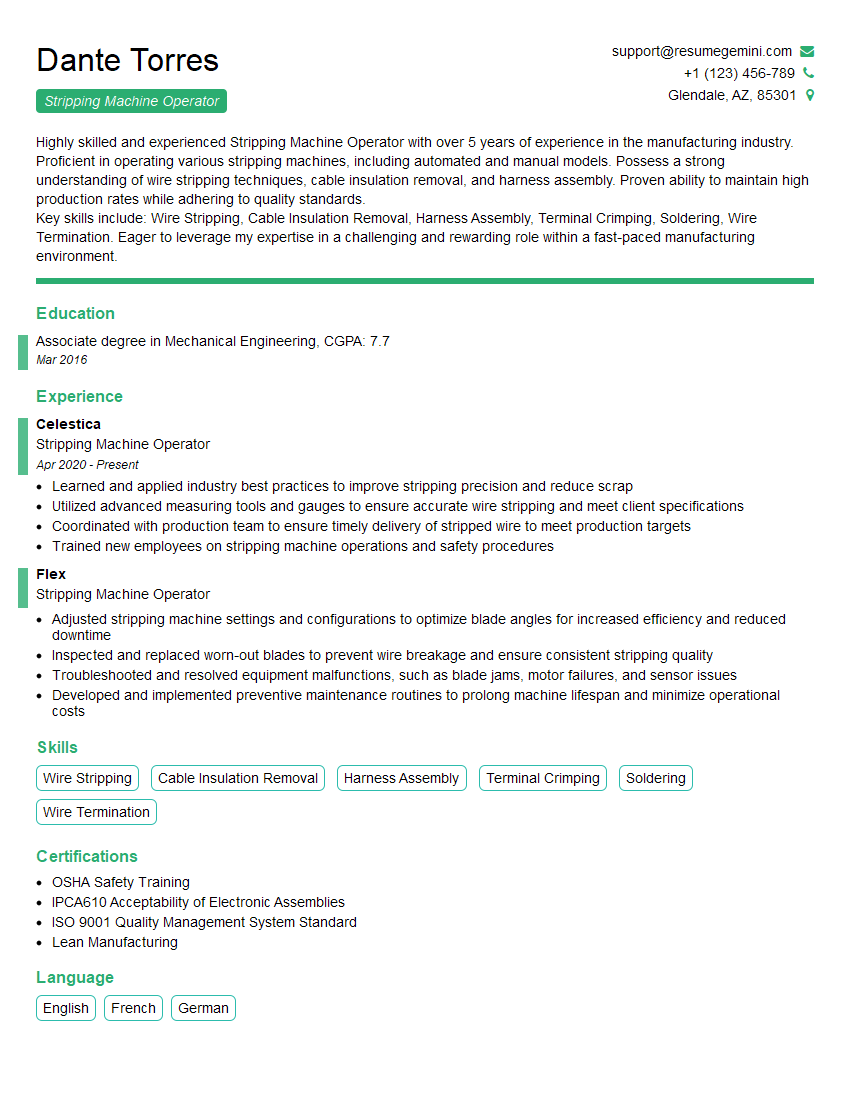

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stripping Machine Operator

1. What type of materials can a stripping machine process?

A stripping machine can process a variety of materials, including:

- Metals (e.g., steel, aluminum, copper)

- Plastics

- Rubber

- Wood

- Glass

2. What are the different types of stripping machines?

Mechanical Stripping Machines

- Use mechanical force to remove the coating

- Types: blade strippers, abrasive brush strippers

Chemical Stripping Machines

- Use chemicals to dissolve the coating

- Types: immersion strippers, spray strippers

Thermal Stripping Machines

- Use heat to soften or vaporize the coating

- Types: flame strippers, hot air strippers

3. What are the factors that affect the selection of a stripping machine?

- Type of material to be stripped

- Thickness of the coating

- Desired surface finish

- Production volume

- Environmental regulations

4. How do you maintain a stripping machine?

- Regularly clean the machine

- Inspect the machine for wear and tear

- Lubricate the machine as recommended by the manufacturer

- Calibrate the machine regularly

- Follow manufacturer’s maintenance schedule

5. What safety precautions should be taken when operating a stripping machine?

- Wear appropriate safety gear

- Follow manufacturer’s safety instructions

- Be aware of potential hazards

- Use proper ventilation

- Keep the work area clean and organized

6. What is the difference between a wet stripper and a dry stripper?

- Wet strippers use a chemical solution to dissolve the coating.

- Dry strippers use mechanical force or heat to remove the coating.

7. What are the advantages and disadvantages of using a stripping machine?

Advantages

- Efficient

- Consistent

- Can handle large volumes

Disadvantages

- Can be expensive

- Can damage the underlying material

- Can create hazardous waste

8. What is the future of stripping machine technology?

- Development of more efficient and environmentally friendly machines

- Increased use of automation

- Integration with other manufacturing processes

9. What are the different types of stripping processes?

- Mechanical stripping

- Chemical stripping

- Thermal stripping

- Laser stripping

10. What is the most important factor to consider when selecting a stripping process?

- The type of material to be stripped

- The thickness of the coating

- The desired surface finish

- The production volume

- The environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stripping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stripping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stripping Machine Operators are responsible for operating and maintaining stripping machines, which are used to remove the outer insulation from wires and cables.

1. Machine Operation

Stripping Machine Operators are required to control and operate stripping machines.

- Load wires and cables into the stripping machine.

- Set up and adjust the machine to strip the insulation to the desired length.

- Monitor the stripping process and make adjustments as needed.

2. Machine Maintenance

Stripping Machine Operators must perform routine maintenance on the machines they operate.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for any signs of wear or damage.

- Report any problems with the machine to the supervisor.

3. Quality Control

Stripping Machine Operators are responsible for ensuring that the stripped wires and cables meet quality standards.

- Inspect the stripped wires and cables for any defects.

- Reject any wires or cables that do not meet the quality standards.

- Keep records of the quality of the stripped wires and cables.

4. Safety

Stripping Machine Operators must follow all safety procedures.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when performing maintenance on the machine.

- Report any unsafe conditions to the supervisor.

Interview Tips

In order to ace an interview, candidates for the Stripping Machine Operator must be well-prepared.

1. Research the company and the position

Before the interview, candidates should research the company and the specific position they are applying for.

- Visit the company’s website to learn about their history, their mission, and their products or services.

- Read the job description carefully and identify the key skills and experience required for the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that candidates for Stripping Machine Operator positions can expect to be asked.

- Tell me about your experience operating stripping machines.

- How do you ensure that the stripped wires and cables meet quality standards?

- What are your safety procedures when operating a stripping machine?

3. Dress professionally

First impressions matter, so candidates should dress professionally for their interview.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

4. Be confident and enthusiastic

Candidates should be confident and enthusiastic during their interview.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be enthusiastic about the position and the company.

By following these tips, candidates can increase their chances of success in an interview for a Stripping Machine Operator position.

Next Step:

Now that you’re armed with the knowledge of Stripping Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stripping Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini