Feeling lost in a sea of interview questions? Landed that dream interview for Stripping Shovel Oiler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stripping Shovel Oiler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

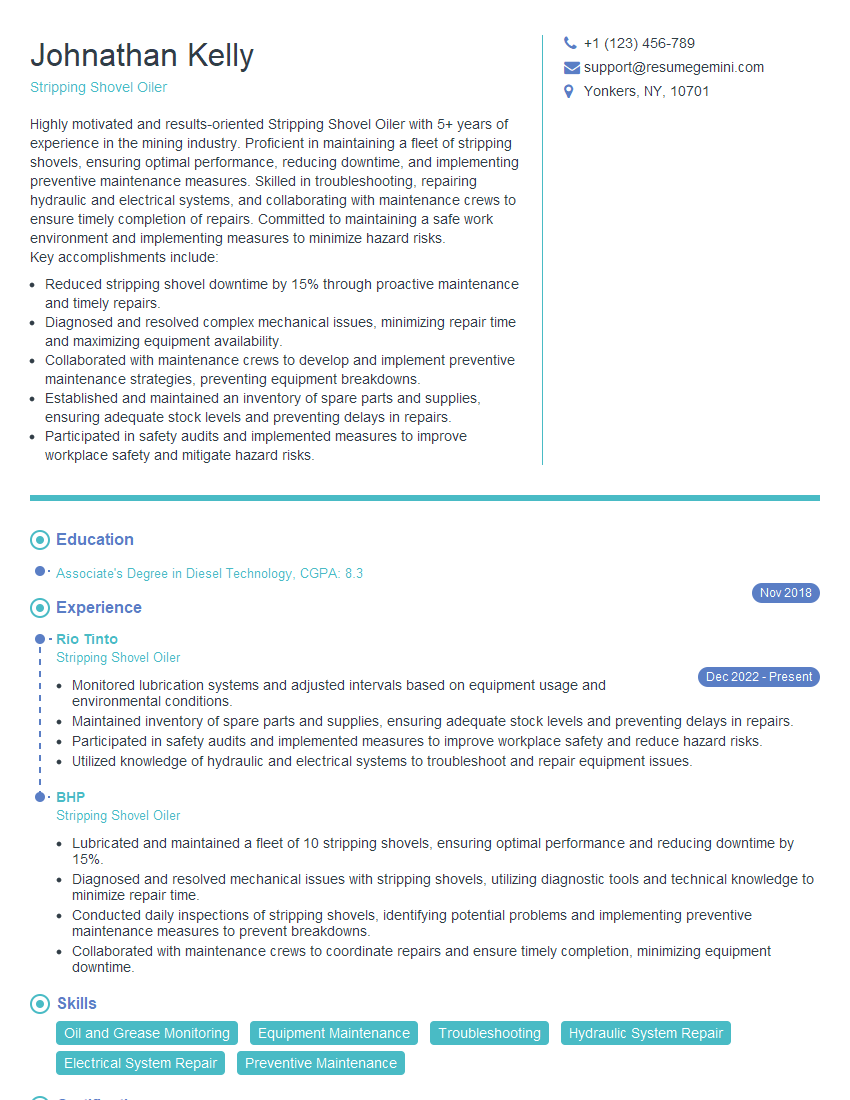

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stripping Shovel Oiler

1. Explain the role of a Stripping Shovel Oiler?

As a Stripping Shovel Oiler, I am responsible for maintaining and lubricating the various components of a stripping shovel, a heavy-duty mining machine used in surface mining. My primary duties include:

- Monitoring and maintaining oil levels in reservoirs and gearboxes.

- Applying lubricants to gears, chains, and other moving parts.

- Inspecting and replacing worn or damaged oil filters.

- Monitoring oil pressure and temperature readings.

- Troubleshooting and resolving minor oil-related issues.

2. Describe the different types of lubricants used in a stripping shovel?

Stripping shovels require a range of lubricants to ensure smooth operation and prevent wear and tear. The types of lubricants I commonly use include:

Engine Oils:

- Heavy-duty diesel engine oils for optimal engine performance.

- Hydraulic oils designed for hydraulic systems, providing power and control.

Gear Oils:

- Industrial gear oils for gearboxes and differentials, reducing friction and wear.

Greases:

- Lithium-based greases for high-temperature applications.

- Calcium-based greases for water-resistant applications.

- Synthetic greases for extreme pressure and high-load situations.

3. How do you ensure the proper lubrication of a stripping shovel?

To ensure proper lubrication, I follow a systematic approach:

- Regularly check oil levels and top up as needed.

- Use the recommended type and quantity of lubricant for each component.

- Replace oil filters according to the manufacturer’s specifications.

- Inspect oil for signs of contamination or excessive wear.

- Lubricate all moving parts as per the lubrication schedule.

- Maintain records of lubrication activities for tracking and future reference.

4. What are the consequences of improper lubrication in a stripping shovel?

Improper lubrication can lead to several detrimental consequences:

- Increased wear and tear on components.

- Reduced efficiency and performance of the shovel.

- Overheating and potential component failure.

- Corrosion and premature aging of parts.

- Increased downtime and costly repairs.

- Environmental hazards due to oil leaks or spills.

5. How do you maintain the cleanliness of oil reservoirs and gearboxes?

Maintaining cleanliness is crucial for optimal lubrication. I follow these practices:

- Regular inspection of oil reservoirs for contamination.

- Cleaning and flushing oil reservoirs during oil changes.

- Using clean oil filters and avoiding contamination during filter changes.

- Monitoring oil condition and replacing it when it becomes contaminated or degraded.

- Applying anti-corrosion measures to prevent moisture and contaminants from entering the system.

6. What are the safety precautions you observe when performing oil-related tasks?

Safety is paramount when handling lubricants:

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Avoid contact with hot oil and lubricated surfaces.

- Handle oil spills promptly and safely.

- Dispose of used oil and filters properly according to environmental regulations.

- Follow established safety procedures and protocols.

7. How do you troubleshoot common oil-related issues in a stripping shovel?

Troubleshooting oil-related issues requires a systematic approach:

- Identify the symptoms and potential causes.

- Check oil levels, pressure, and temperature readings.

- Inspect oil condition and look for signs of contamination or wear.

- Tighten loose connections or replace worn components as needed.

- Consult with maintenance technicians or refer to technical manuals for guidance.

8. How do you stay updated on best practices and advancements in lubrication?

To stay abreast of industry advancements, I engage in the following:

- Attend training workshops and seminars.

- Read industry publications and technical journals.

- Consult with equipment manufacturers and lubrication suppliers.

- Participate in online forums and discussion groups.

- Obtain industry certifications, such as the NLGI Certified Lubrication Technician.

9. Can you describe a situation where you successfully resolved a complex oil-related issue in a stripping shovel?

In one instance, the stripping shovel experienced a sudden loss of oil pressure in the main hydraulic system. I quickly checked the oil level, which was normal, and inspected the oil condition, which showed no signs of contamination. After further troubleshooting, I discovered a loose connection in the hydraulic line. I tightened the connection, refilled the hydraulic reservoir, and the system resumed normal operation without any further issues.

10. Why are you interested in this Stripping Shovel Oiler position?

I am eager to join your team as a Stripping Shovel Oiler because I am confident in my abilities to contribute to the smooth operation and maintenance of your mining equipment. My technical skills, attention to detail, and commitment to safety align with the requirements of this role. I am eager to apply my expertise in lubrication and maintenance to ensure the reliability and productivity of your stripping shovels.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stripping Shovel Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stripping Shovel Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stripping Shovel Oiler is responsible for performing preventative maintenance and lubrication on large-scale stripping shovels. They ensure the smooth operation of the shovels and minimize downtime for repairs.

1. Lubrication and Maintenance

The primary responsibility of a Stripping Shovel Oiler is to lubricate and maintain the shovel’s moving parts, including gears, bearings, and hydraulic systems. They follow lubrication schedules and use specialized equipment to apply lubricants and greases.

2. Inspections and Troubleshooting

Oil Spills are also responsible for conducting regular inspections of the shovel’s components and identifying potential issues. They monitor oil levels and pressures, check for leaks, and troubleshoot any malfunctions or breakdowns.

3. Oil Sampling and Analysis

To ensure the proper functioning of the shovel, Oil Spills collect and analyze oil samples from the shovel’s systems. They perform basic tests to identify any contamination or wear and tear, and report their findings to maintenance supervisors.

4. Safety and Compliance

Oil Spills must adhere to all safety regulations and follow established maintenance protocols. They wear appropriate personal protective equipment (PPE) and prioritize the safety of themselves and others during maintenance tasks.

Interview Tips

Preparing for an interview for a Stripping Shovel Oiler position requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace the interview:

1. Know the Industry and Equipment

Research the mining industry and familiarize yourself with the operations of stripping shovels. Understand the different components of the shovel and their functions, as well as common maintenance procedures.

2. Highlight Maintenance Experience

Emphasize your experience in performing maintenance tasks, including lubrication, inspections, and troubleshooting. Quantify your accomplishments and provide specific examples of how you resolved issues on previous projects.

3. Demonstrate Safety Awareness

Stress the importance of safety in your work and provide examples of how you have prioritized safety in your previous roles. Explain your understanding of PPE, hazard identification, and emergency procedures.

4. Show Knowledge of Oil Analysis

Explain your understanding of oil sampling and analysis. Discuss the different tests you have performed and how you interpret the results to identify potential problems.

5. Be Prepared for Common Interview Questions

Anticipate common interview questions related to your technical skills, safety practices, and experience. Prepare concise and well-structured answers that highlight your qualifications and enthusiasm for the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stripping Shovel Oiler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stripping Shovel Oiler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.