Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Structural and Ornamental Metalwork Steel Fabricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

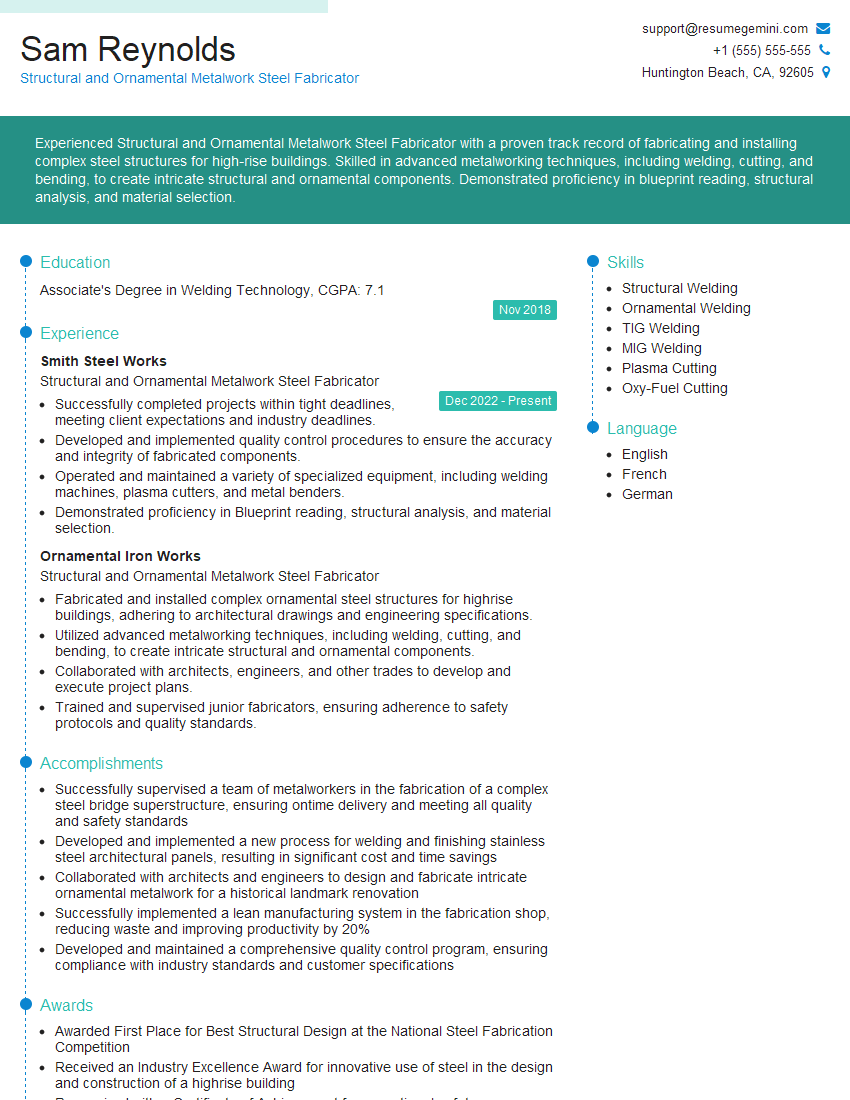

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Structural and Ornamental Metalwork Steel Fabricator

1. What techniques do you use to ensure the accuracy and precision of your steel fabrications?

In order to ensure the accuracy and precision of my steel fabrications, I use a combination of techniques. These include:

- Detailed planning and engineering drawings

- State-of-the-art cutting and welding equipment

- Quality control measures throughout the fabrication process

- Regular calibration and maintenance of equipment

- Skilled and experienced fabricators

2. How do you interpret and use engineering drawings and specifications for structural steel fabrication?

Understanding the Drawings

- Review the drawings thoroughly to understand the overall scope and requirements.

- Identify the dimensions, tolerances, and material specifications.

- Study the details, such as connections, welding symbols, and any special requirements.

Using the Information

- Translate the drawings into fabrication instructions for the shop floor.

- Determine the necessary materials, equipment, and tooling.

- Plan the fabrication sequence and ensure compliance with specifications.

3. Describe the different types of welding processes you are proficient in and the applications where each is most suitable.

I am proficient in various welding processes, including:

- Shielded Metal Arc Welding (SMAW): Suitable for general fabrication, repair work, and thick materials.

- Gas Metal Arc Welding (GMAW): Ideal for thin materials, high-speed welding, and automated processes.

- Gas Tungsten Arc Welding (GTAW): Used for high-quality welds, thin materials, and intricate work.

- Flux-Cored Arc Welding (FCAW): Versatile process suitable for both thick and thin materials, with high deposition rates.

- Submerged Arc Welding (SAW): Automated process used for high-volume production of large, thick components.

4. How do you ensure the structural integrity of steel fabrications?

To ensure the structural integrity of steel fabrications, I adhere to the following measures:

- Material Selection: Choosing the appropriate steel grade and thickness based on load requirements and environmental factors.

- Proper Welding Techniques: Using qualified welders and following industry standards for welding procedures and quality control.

- Quality Control: Implementing non-destructive testing methods such as visual inspection, ultrasonic testing, and magnetic particle testing to verify weld quality.

- Load Analysis: Calculating and analyzing loads to ensure that the structure can withstand the intended forces.

- Compliance with Codes: Adhering to applicable building codes and industry standards to ensure safety and reliability.

5. What is your experience in fabricating and installing ornamental metalwork?

I have extensive experience in fabricating and installing ornamental metalwork, including:

- Handrails and Balustrades: Creating custom designs and fabricating intricate components for both interior and exterior applications.

- Gates and Fences: Designing and fabricating ornamental gates and fences to enhance security and aesthetics.

- Decorative Elements: Producing decorative metalwork elements such as scrolls, finials, and rosettes to add architectural interest.

- Installation: Installing ornamental metalwork components safely and securely, ensuring proper alignment and functionality.

6. How do you handle complex design requirements for ornamental metalwork?

When handling complex design requirements for ornamental metalwork, I follow a systematic approach:

- Collaboration: Working closely with designers and architects to understand the vision and technical specifications.

- Prototyping: Creating prototypes to test designs and ensure feasibility before full-scale production.

- Technical Expertise: Utilizing my knowledge of metalworking techniques and materials to find innovative solutions.

- Attention to Detail: Paying meticulous attention to detail to achieve intricate and high-quality finishes.

- Craftsmanship: Combining traditional craftsmanship with modern fabrication methods to create unique and visually appealing pieces.

7. What is your experience in working with different types of steel alloys?

I have experience in working with a wide range of steel alloys, including:

- Carbon Steel: Common and versatile alloy used in general fabrication and construction.

- Alloy Steel: Stronger and more corrosion-resistant than carbon steel, suitable for demanding applications.

- Stainless Steel: Highly resistant to corrosion and heat, commonly used in food processing and architectural applications.

- Tool Steel: Hard and wear-resistant, used for cutting and forming tools.

- High-Strength Low-Alloy (HSLA) Steel: Increased strength and toughness compared to carbon steel, used in bridges and other structural applications.

8. How do you ensure quality control in your fabrication process?

I implement a comprehensive quality control process to ensure the highest standards in my fabrication process:

- Material Inspection: Verifying the quality and specifications of incoming materials.

- In-Process Inspections: Monitoring fabrication steps to identify and correct any deviations.

- Non-Destructive Testing: Using methods such as ultrasonic testing and magnetic particle testing to assess weld quality and material integrity.

- Final Inspection: Conducting a thorough inspection of finished products against specifications and customer requirements.

- Documentation: Maintaining detailed records of all inspections and test results for traceability and accountability.

9. What is your experience in using computer-aided design (CAD) software for steel fabrication?

I am proficient in using CAD software for steel fabrication, including:

- AutoCAD: Creating 2D and 3D models, generating drawings, and detailing fabrication processes.

- SolidWorks: Designing complex 3D models, performing structural analysis, and generating fabrication instructions.

- Tekla Structures: Modeling and detailing steel structures, creating production drawings, and managing project data.

- CAM Software: Generating CNC programs for automated cutting, welding, and other fabrication processes.

10. How do you stay updated with the latest advancements in steel fabrication technology?

To stay updated with the latest advancements in steel fabrication technology, I engage in the following activities:

- Industry Events: Attending conferences, trade shows, and workshops to learn about new technologies and best practices.

- Technical Publications: Reading industry journals, magazines, and technical papers to keep abreast of current trends.

- Online Research: Regularly exploring online resources, forums, and manufacturer websites for information on new products and techniques.

- Training and Certification: Participating in training programs and obtaining certifications to enhance my knowledge and skills.

- Networking: Connecting with other professionals in the field to exchange ideas and share experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Structural and Ornamental Metalwork Steel Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Structural and Ornamental Metalwork Steel Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Structural and Ornamental Metalwork Steel Fabricator holds the responsibility of cutting, shaping, and assembling structural and ornamental metalwork components. They work in collaboration with engineers, architects, and other specialists to bring blueprints and designs to life. Their work requires precision, technical expertise, and a commitment to safety.

1. Fabrication and Assembly

The core responsibility of a Structural and Ornamental Metalwork Steel Fabricator lies in fabricating and assembling metal components used in the construction industry. This involves:

- Interpreting engineering drawings and blueprints to understand the specifications of the metalwork required.

- Selecting and cutting the appropriate type and size of metal, using tools such as plasma cutters, oxy-fuel torches, or saws.

- Shaping and bending the metal into the desired form, utilizing equipment like press brakes, rolling machines, or hammers.

- Assembling the fabricated components into complete structures, ensuring proper fit and alignment.

2. Welding and Joining

To join metal components, Structural and Ornamental Metalwork Steel Fabricators employ various welding and joining techniques, including:

- Arc welding, using methods like shielded metal arc welding (SMAW) or gas metal arc welding (GMAW), to fuse metal pieces together.

- Oxy-fuel welding, using a combination of oxygen and fuel gases to create a high-temperature flame for cutting and welding.

- Riveting, applying mechanical fasteners to connect metal parts.

3. Finishing and Inspection

Once the metalwork is fabricated and assembled, Structural and Ornamental Metalwork Steel Fabricators perform finishing and inspection tasks:

- Grinding and polishing the metal surfaces to remove burrs and rough edges.

- Applying protective coatings, such as paint or galvanizing, to prevent corrosion and enhance durability.

- Conducting thorough inspections to ensure that the fabricated metalwork meets the required specifications and safety standards.

4. Equipment Maintenance and Safety

Structural and Ornamental Metalwork Steel Fabricators are responsible for maintaining the equipment they use, including:

- Conducting regular inspections and servicing of welding machines, cutting tools, and other fabrication equipment.

- Ensuring that all equipment is in good working order to prevent accidents and maintain productivity.

- Adhering to safety protocols, wearing appropriate protective gear, and following established safety procedures to minimize risks.

Interview Tips

Preparing for an interview for a Structural and Ornamental Metalwork Steel Fabricator role requires a combination of technical knowledge and a demonstration of your skills and experience.

1. Research the Company and Role

Before the interview, thoroughly research the company you’re applying to and the specific role you’re seeking. Familiarize yourself with their products, services, and industry reputation. Understanding the company’s culture and values will also help you align your qualifications and aspirations with their needs.

2. Highlight Your Technical Skills

Emphasize your technical proficiency in metal fabrication, welding, and finishing techniques. Provide specific examples of projects you’ve worked on, highlighting your ability to read blueprints, operate equipment, and produce high-quality metalwork. Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your contributions.

3. Showcase Your Experience

Describe your previous work experience in detail, emphasizing your responsibilities and accomplishments as a Structural and Ornamental Metalwork Steel Fabricator. Use the STAR method (Situation, Task, Action, Result) to provide structured and impactful answers to interview questions.

4. Prepare for Common Interview Questions

Research common interview questions for this role. Practice your answers, ensuring that you articulate your skills, experience, and qualifications clearly and concisely. Consider questions related to your technical abilities, safety practices, and ability to work in a team environment.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for your interview. This demonstrates your respect for the interviewer and the company. Maintain a positive attitude and be enthusiastic about the opportunity to contribute your skills to their team.

Next Step:

Now that you’re armed with the knowledge of Structural and Ornamental Metalwork Steel Fabricator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Structural and Ornamental Metalwork Steel Fabricator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini