Feeling lost in a sea of interview questions? Landed that dream interview for Sub Arc Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sub Arc Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

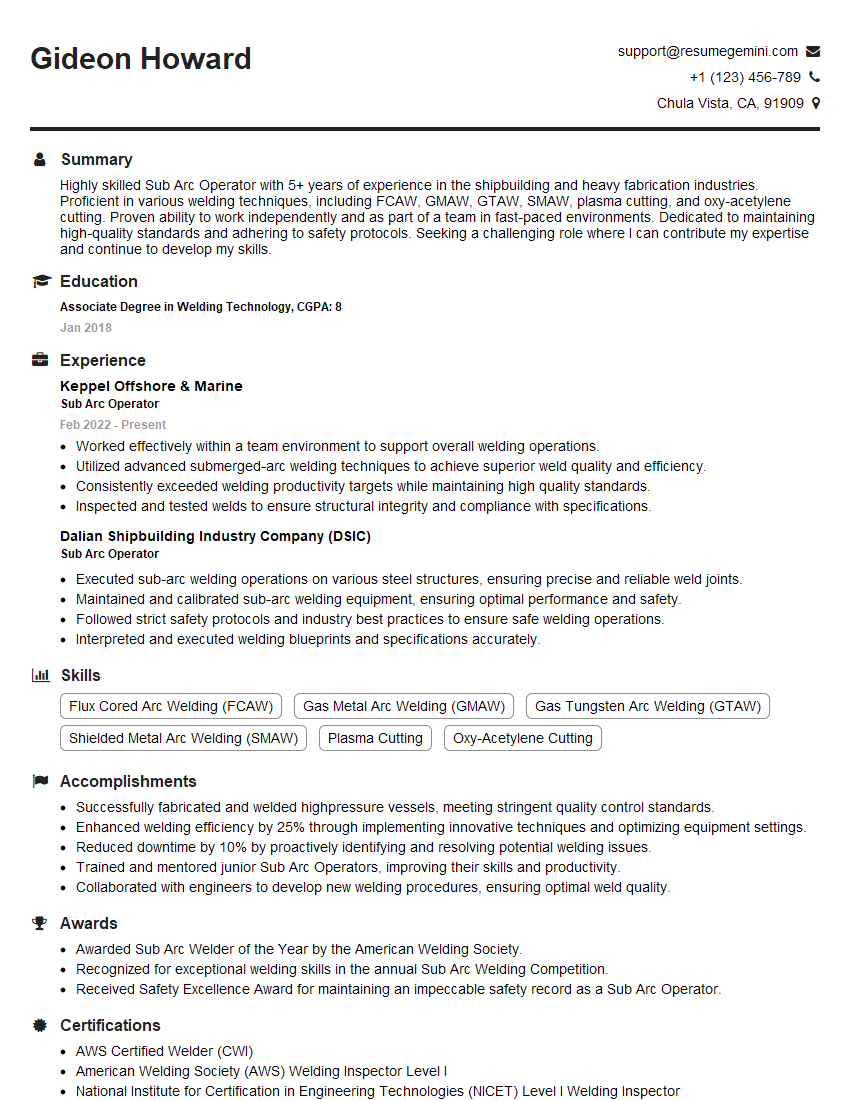

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sub Arc Operator

1. What are the key parameters that you consider when setting up a Sub Arc Welding (SAW) machine?

- Welding current

- Voltage

- Wire feed speed

- Travel speed

- Flux type and amount

- Electrode type and diameter

- Shielding gas

- Joint preparation

- Material thickness

- Welding position

2. Explain the different types of fluxes used in SAW and their applications.

- Acidic fluxes: Used for welding carbon steels and low-alloy steels, produce a thin, glassy slag that is easy to remove, but can be corrosive if not removed properly.

- Basic fluxes: Used for welding high-alloy steels and stainless steels, produce a thick, viscous slag that is more difficult to remove, but provides better protection against oxidation and corrosion.

- Neutral fluxes: Used for welding a variety of materials, produce a slag that is intermediate in properties between acidic and basic fluxes.

- Metal-cored fluxes: Contain metal powder in addition to fluxing agents, provide higher deposition rates and better weld quality.

subheading of the answer

- Bonded fluxes: Consist of flux particles bonded together with a resin or adhesive, provide better flux distribution and reduce spatter.

- Agglomerated fluxes: Consist of flux particles fused together by heat, provide higher flux density and better electrical conductivity.

3. What are the common defects associated with SAW and how can they be prevented?

- Lack of fusion: Occurs when the weld metal does not fully penetrate the joint, can be prevented by using proper welding parameters and joint preparation.

- Porosity: Occurs when gas bubbles are trapped in the weld metal, can be prevented by using dry flux and shielding gas.

- Slag inclusions: Occurs when flux is trapped in the weld metal, can be prevented by using proper flux removal techniques.

- Undercut: Occurs when the weld metal melts and flows away from the joint, can be prevented by using proper welding parameters and joint preparation.

- Overhead: Occurs when the weld metal flows downward due to gravity, can be prevented by using proper welding techniques and equipment.

4. How do you maintain and troubleshoot SAW equipment?

- Regularly inspect and clean the equipment: Check for any loose connections, worn parts, or damage.

- Calibrate the equipment: Ensure that the welding parameters are set accurately.

- Troubleshoot common problems: Quickly identify and resolve any issues that may arise during welding.

- Follow the manufacturer’s instructions: Refer to the manual for proper maintenance and troubleshooting procedures.

5. What are the safety precautions that you must observe when operating a SAW machine?

- Wear appropriate personal protective equipment (PPE): Including welding helmet, gloves, and protective clothing.

- Ensure proper ventilation: To remove welding fumes and gases.

- Keep the work area clean and organized: To prevent tripping hazards and fires.

- Follow proper handling and storage procedures: For welding wire, flux, and equipment.

- Be aware of potential electrical hazards: And take precautions to prevent electrical shock.

- Never operate a SAW machine if you are under the influence of alcohol or drugs.

6. What are the advantages and disadvantages of SAW compared to other welding processes?

Advantages

- High deposition rate

- Deep penetration

- Good weld quality

- High productivity

- Versatile

Disadvantages

- Slow travel speed

- Limited visibility

- Fumes and gases

- More expensive equipment

7. How do you ensure that your welds meet the required specifications and standards?

- Follow the welding procedure specifications (WPS): Developed by qualified welding engineers.

- Use qualified welding materials: Meet the requirements of the WPS.

- Properly prepare the joint: Clean, free of contaminants, and properly aligned.

- Use the correct welding parameters: As specified in the WPS.

- Perform non-destructive testing (NDT): To verify the quality of the welds.

8. What is your experience with welding exotic materials, such as stainless steel or aluminum?

- Stainless steel: Requires special welding techniques and filler materials to prevent corrosion and maintain strength.

- Aluminum: Requires special shielding gases and techniques to prevent oxidation and contamination.

9. How do you stay updated with the latest advancements in SAW technology?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Consult with welding equipment manufacturers and suppliers

- Participate in online forums and discussion groups

- Seek opportunities for professional development

10. Can you describe a time when you faced a challenging welding situation and how you overcame it?

- Describe the situation: Clearly and concisely.

- Explain your approach: How you analyzed the problem and developed a solution.

- Highlight your skills and abilities: How you applied your knowledge and experience to overcome the challenge.

- Quantify the results: If possible, provide specific metrics or examples to demonstrate the success of your efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sub Arc Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sub Arc Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sub Arc Operators are responsible for operating and maintaining Submerged Arc Welding (SAW) equipment to join metal components. Their primary duties include:

1. Welding Operations

Execute Submerged Arc Welding (SAW) processes to join metal components according to specified blueprints and welding procedures.

- Set up and operate SAW equipment, including welding machines, wire feeders, and flux recovery systems.

- Monitor welding parameters such as voltage, amperage, and travel speed to ensure optimal weld quality.

- Inspect welds visually and using non-destructive testing methods to verify compliance with quality standards.

2. Equipment Maintenance

Perform routine maintenance and repairs on SAW equipment to ensure optimal performance and safety.

- Clean and inspect welding equipment regularly, including nozzles, tips, and wires.

- Troubleshoot and resolve welding equipment malfunctions to minimize downtime.

- Calibrate and adjust welding equipment according to manufacturer’s specifications.

3. Quality Control

Implement quality control measures to ensure the integrity and reliability of welds.

- Adhere to established welding procedures and quality standards.

- Conduct visual inspections and non-destructive testing to verify weld quality.

- Document welding parameters and inspection results for quality control purposes.

4. Safety and Compliance

Maintain a safe and compliant work environment in accordance with industry regulations.

- Follow established safety protocols and wear appropriate personal protective equipment.

- Ensure work area is well-ventilated and free of hazards.

- Comply with environmental regulations related to welding operations.

Interview Tips

To ace an interview for a Sub Arc Operator position, candidates should:

1. Research the Company and Role

Familiarize yourself with the company’s history, products or services, and industry reputation. Understand the specific responsibilities and requirements of the Sub Arc Operator role.

- Review the job description carefully and identify the key skills and experience the employer is seeking.

- Visit the company’s website and social media pages to gather information about their culture and values.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in Sub Arc Welding (SAW) techniques, equipment maintenance, and quality control procedures.

- Provide specific examples of projects or tasks where you successfully applied these skills.

- Quantify your accomplishments whenever possible, using metrics such as increased productivity or improved weld quality.

3. Demonstrate Safety Consciousness

Sub Arc Operators must prioritize safety in their work. Highlight your commitment to following established safety protocols and maintaining a safe work environment.

- Describe your experience in using personal protective equipment, adhering to safety regulations, and identifying potential hazards.

- Emphasize your understanding of the importance of proper ventilation and environmental compliance in welding operations.

4. Prepare for Technical Questions

Interviewers may ask technical questions to assess your knowledge of SAW welding principles and equipment. Be prepared to discuss topics such as:

- Different types of SAW fluxes and their applications.

- Factors affecting weld quality, such as voltage, amperage, and travel speed.

- Troubleshooting common SAW equipment malfunctions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sub Arc Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sub Arc Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.