Feeling lost in a sea of interview questions? Landed that dream interview for Submarine Vertical Launch System Tube Maintenance Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Submarine Vertical Launch System Tube Maintenance Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

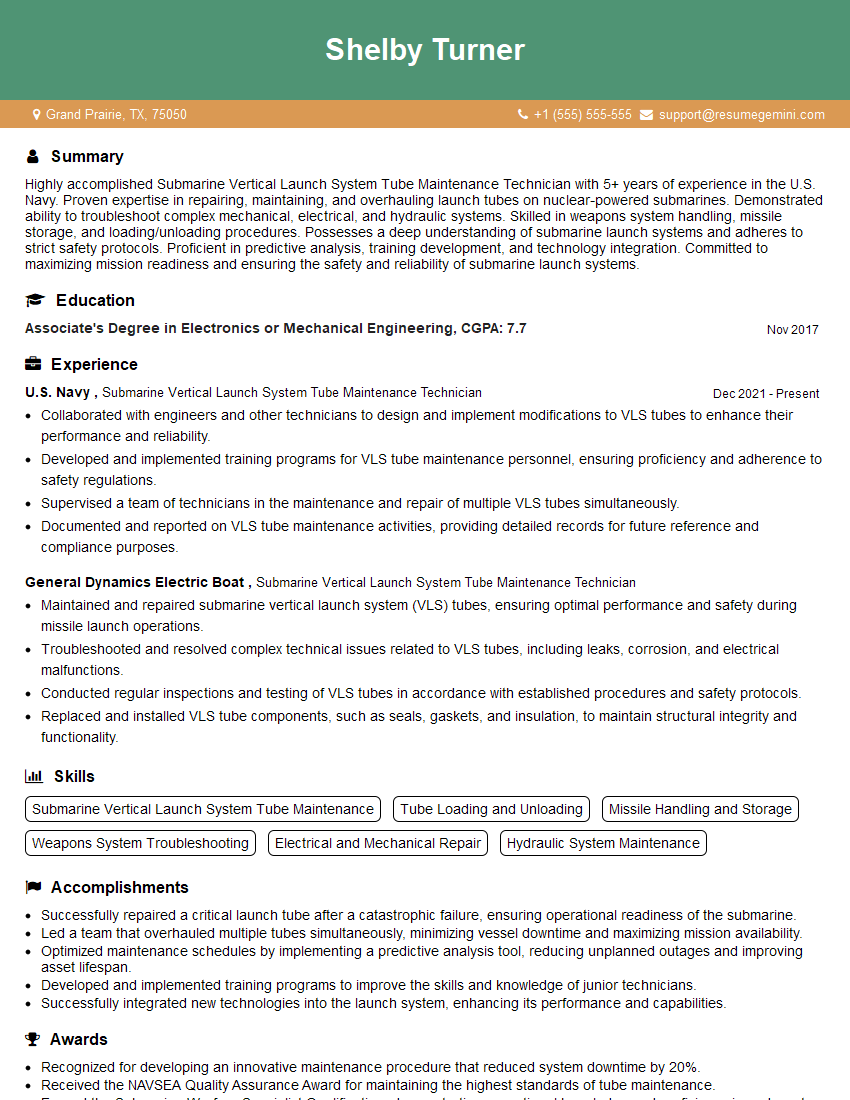

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Submarine Vertical Launch System Tube Maintenance Technician

1. Describe the process of troubleshooting a Submarine Vertical Launch System (VLS) tube that is not pressurizing properly?

- Confirm that the VLS system is powered on and operational.

- Verify that the pressure source is providing the correct pressure.

- Check the VLS tube for leaks using a leak detection solution.

- Inspect the VLS tube for any damage or obstructions.

- Test the VLS tube’s pressure relief valve to ensure it is functioning properly.

- Determine if the issue is with the VLS tube itself or with the associated piping or valves.

2. Explain the procedures for handling and storing VLS tubes?

Storage

- Store VLS tubes in a clean, dry, and temperature-controlled environment.

- Protect VLS tubes from moisture, dust, and other contaminants.

- Handle VLS tubes with care to avoid damage.

Handling

- Use proper lifting equipment to move VLS tubes.

- Inspect VLS tubes for damage before handling.

- Wear appropriate personal protective equipment (PPE) when handling VLS tubes.

3. What are the safety precautions to be taken when working on a VLS system?

- Ensure the VLS system is de-energized and depressurized before performing any maintenance.

- Wear appropriate PPE, including gloves, safety glasses, and a hard hat.

- Follow established lockout/tagout procedures.

- Be aware of the potential hazards associated with working with high-pressure systems.

- Never work alone when performing maintenance on a VLS system.

4. How do you test the functionality of a VLS tube’s missile interface system?

- Connect a missile simulator to the VLS tube’s missile interface system.

- Conduct electrical continuity tests to ensure proper connections.

- Perform functional tests to verify the missile interface system’s ability to receive, decode, and process commands.

- Inspect the missile interface system for any damage or defects.

5. Describe the maintenance procedures for VLS tube seals and gaskets?

- Inspect seals and gaskets regularly for damage or wear.

- Replace seals and gaskets as needed using specified materials and procedures.

- Lubricate seals and gaskets according to manufacturer’s instructions.

- Follow proper torque specifications when tightening seals and gaskets.

6. How do you ensure that a VLS tube is properly aligned and secured after maintenance?

- Use precision alignment tools to position the VLS tube correctly.

- Tighten the VLS tube’s securing bolts to the specified torque.

- Verify the VLS tube’s alignment and security using a level or other measurement devices.

7. Explain the process of performing a hydrostatic pressure test on a VLS tube?

- Install a pressure gauge and fill the VLS tube with water.

- Increase the pressure gradually and monitor the pressure gauge.

- Hold the pressure at the specified test pressure for a predetermined period of time.

- Observe the VLS tube for any leaks or deformations.

8. Describe the inspection procedures for VLS tube interiors?

- Use a borescope or other inspection device to visually examine the VLS tube’s interior.

- Inspect for corrosion, cracks, or other damage.

- Check the condition of seals, gaskets, and other components.

- Document and report any findings.

9. How do you maintain and calibrate the sensors and instrumentation associated with a VLS system?

- Follow established calibration procedures and schedules.

- Use certified calibration equipment and standards.

- Verify the accuracy and functionality of sensors and instruments.

- Document and record calibration results.

10. Explain the importance of adhering to quality assurance and control procedures when working on VLS systems?

- Ensures the safety and reliability of VLS systems.

- Minimizes the risk of system failures and malfunctions.

- Maintains compliance with industry standards and regulations.

- Facilitates effective troubleshooting and maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Submarine Vertical Launch System Tube Maintenance Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Submarine Vertical Launch System Tube Maintenance Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Submarine Vertical Launch System (VLS) Tube Maintenance Technicians play a vital role in ensuring the operational readiness of submarines. Their primary responsibilities include:

1. VLS Tube Maintenance and Inspection

Conducting routine inspections, preventive maintenance, and repairs on VLS tubes, ensuring they meet operational standards.

- Inspecting tube interiors for corrosion, damage, or blockages.

- Performing leak tests and pressure checks to verify tube integrity.

2. Troubleshooting and Repair

Diagnosing and repairing malfunctions in VLS tubes, including hydraulic, electrical, and mechanical systems.

- Identifying and resolving issues with missile launch systems, door mechanisms, and sealing components.

- Working closely with engineers and other technicians to determine appropriate repair solutions.

3. Equipment Calibration and Testing

Calibrating and testing VLS equipment, such as missile interface units, control systems, and power supplies.

- Ensuring proper functioning of launch sequence components.

- Performing data acquisition and analysis to verify equipment performance.

4. Documentation and Reporting

Maintaining accurate records of all maintenance activities, inspections, and repairs.

- Preparing technical reports and logs for documentation purposes.

- Communicating maintenance status and recommendations to supervisors and other stakeholders.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Submarine Vertical Launch System Tube Maintenance Technician position:

1. Research the Company and Position

Familiarize yourself with the company’s history, mission, and submarine capabilities. Research the specific VLS system you will be working on and its operational requirements.

- Visit the company website and read industry publications for relevant information.

- Speak to current or former employees to gain insights into the company culture and work environment.

2. Emphasize Relevant Skills and Experience

Highlight your technical abilities in VLS maintenance and repair. Quantify your experience with specific examples that demonstrate your proficiency.

- Provide details about your involvement in troubleshooting and resolving complex VLS issues.

- Showcase your experience with equipment calibration, testing, and documentation.

3. Prepare for Technical Questions

You may be asked technical questions to assess your knowledge and problem-solving abilities. Prepare for questions related to VLS tube construction, launch sequence, and maintenance procedures.

- Review technical manuals and documentation to enhance your understanding of the VLS system.

- Practice answering common technical questions in a clear and concise manner.

4. Demonstrate Teamwork and Safety Awareness

VLS maintenance often involves collaboration with other technicians and engineers. Emphasize your ability to work effectively as part of a team and your commitment to safety regulations.

- Provide examples of successful collaborations and how you contributed to project outcomes.

- Explain your understanding of safety protocols and your adherence to them in a submarine environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Submarine Vertical Launch System Tube Maintenance Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Submarine Vertical Launch System Tube Maintenance Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.