Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sugar Boiler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

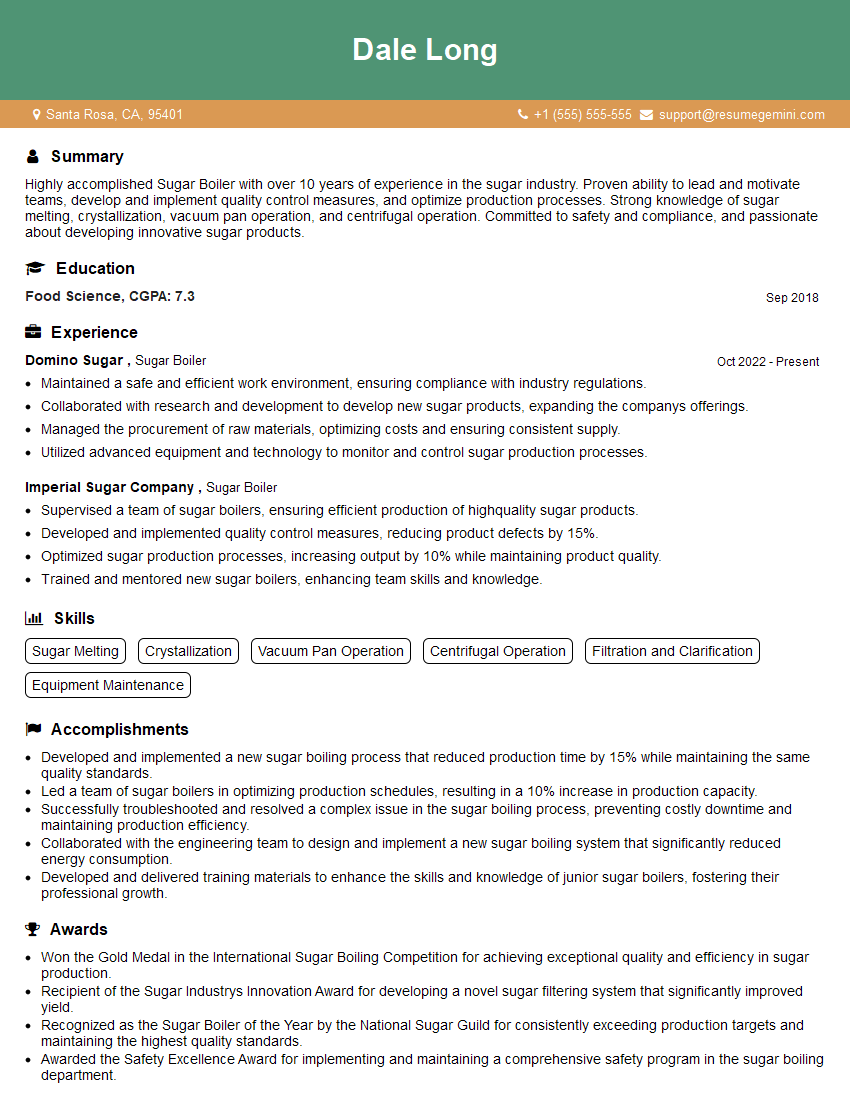

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sugar Boiler

1. Explain the process of sugar boiling in detail.

- Start by dissolving sugar in water to create a sugar solution.

- Heat the sugar solution to a specific temperature, typically between 212°F (100°C) and 250°F (121°C).

- As the sugar solution heats, the water evaporates and the sugar concentration increases.

- Continue heating the sugar solution until it reaches the desired concentration, which is determined by the specific type of sugar being boiled.

- Once the desired concentration is reached, remove the sugar solution from the heat and allow it to cool.

2. Describe the different types of sugar boiling methods and when each method is appropriate.

Vacuum Pan Boiling

- Used to produce high-quality sugar with a consistent crystal size.

- Sugar solution is heated in a vacuum pan under reduced pressure, which lowers the boiling point and allows for more controlled evaporation.

Open Pan Boiling

- Traditional method of sugar boiling used for smaller-scale production.

- Sugar solution is heated in an open pan, and the evaporation rate is controlled by adjusting the heat and stirring the solution.

Continuous Boiling

- Used in large-scale sugar production.

- Sugar solution is continuously fed into a boiling chamber, and the evaporated water is removed through a vacuum system.

3. What are the critical control points in the sugar boiling process and how do you ensure they are met?

- Temperature: Control the temperature of the sugar solution to achieve the desired sugar concentration.

- Evaporation rate: Manage the evaporation rate to prevent crystallization.

- Crystallization: Monitor the sugar solution for signs of crystallization and adjust the boiling process accordingly.

- Hygiene: Maintain a clean and sanitary environment to prevent contamination.

4. How do you troubleshoot common problems that occur during sugar boiling?

- Crystallization: Lower the temperature or add water to the sugar solution to prevent crystallization.

- Scorching: Adjust the heat and stir the sugar solution more frequently to prevent scorching.

- Overheating: Remove the sugar solution from the heat and allow it to cool if it becomes overheated.

- Contamination: Discard the sugar solution if it becomes contaminated.

5. Describe the different grades of sugar and how they are used.

- Granulated sugar: Common table sugar used for baking and sweetening beverages.

- Caster sugar: Fine-grained sugar used for dusting pastries and making meringues.

- Demerara sugar: Coarse-grained sugar with a slightly caramelized flavor used in baked goods and desserts.

- Brown sugar: Moist sugar with a molasses content used for baking and adding flavor to dishes.

- Confectioners’ sugar: Powdered sugar used for frosting and dusting baked goods.

6. How do you ensure the quality of the sugar produced?

- Monitor the boiling process to control temperature and evaporation rate.

- Inspect the sugar for color, texture, and taste.

- Use standardized recipes and procedures to ensure consistency.

- Implement quality control measures to detect and eliminate defects.

7. Describe the different equipment used in sugar boiling and how each piece of equipment contributes to the process.

- Sugar boiler: Vessel used to heat and evaporate the sugar solution.

- Thermometer: Used to monitor the temperature of the sugar solution.

- Refractometer: Used to measure the sugar concentration of the solution.

- Stirrer: Used to agitate the sugar solution and prevent crystallization.

- Vacuum pump: Used to create a vacuum in the vacuum pan boiling process.

8. What safety precautions should be taken when working with sugar boiling equipment?

- Wear protective gear, including gloves, apron, and safety glasses.

- Keep the work area clean and free of spills.

- Be aware of the potential for burns and take precautions to avoid them.

- Follow all operating instructions and safety procedures.

9. How do you stay up-to-date with the latest advancements in sugar boiling technology?

- Attend industry conferences and workshops.

- Read trade publications and research papers.

- Network with other sugar boilers and industry professionals.

- Explore and implement new technologies that improve efficiency and product quality.

10. How do you handle working in a fast-paced, demanding environment?

- Prioritize tasks and manage time effectively.

- Stay calm under pressure and make decisions quickly.

- Work well as part of a team and communicate effectively.

- Maintain focus and accuracy even when working long hours.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sugar Boiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sugar Boiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sugar Boilers are responsible for the operation and maintenance of sugar boiling equipment, and for the production of high-quality sugar products. They must have a thorough understanding of the sugar boiling process, and be able to make adjustments to the equipment as needed to ensure that the sugar is produced to the correct specifications. They must also be able to work independently and as part of a team, and be able to follow instructions accurately.

1. Operate and maintain sugar boiling equipment

Sugar Boilers are responsible for the operation and maintenance of sugar boiling equipment, including vacuum pans, crystallizers, and centrifuges. They must be able to start up, shut down, and operate the equipment safely and efficiently, and be able to troubleshoot and repair any problems that may occur. They must also be able to clean and sanitize the equipment according to established procedures.

- Operate vacuum pans to boil sugar solutions to the desired concentration.

- Control the crystallization process to produce sugar crystals of the desired size and shape.

- Operate centrifuges to separate sugar crystals from the molasses.

- Clean and sanitize sugar boiling equipment according to established procedures.

2. Produce high-quality sugar products

Sugar Boilers are responsible for producing high-quality sugar products, including granulated sugar, brown sugar, and molasses. They must be able to adjust the boiling process to produce sugar products that meet the desired specifications, and be able to identify and correct any problems that may occur during the production process. They must also be able to package and store sugar products according to established procedures.

- Adjust the boiling process to produce sugar products that meet the desired specifications.

- Identify and correct any problems that may occur during the production process.

- Package and store sugar products according to established procedures.

3. Work independently and as part of a team

Sugar Boilers must be able to work independently and as part of a team. They must be able to follow instructions accurately, and be able to work safely and efficiently in a fast-paced environment. They must also be able to communicate effectively with other team members, and be able to work under pressure.

- Follow instructions accurately.

- Work safely and efficiently in a fast-paced environment.

- Communicate effectively with other team members.

- Work under pressure.

Interview Tips

To ace the interview for a Sugar Boiler position, it is important to be prepared and to have a good understanding of the key job responsibilities. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to learn more about the specific requirements of the position. You can find information about the company on their website, and you can also read online reviews to get a sense of what it is like to work there. It is also helpful to learn about the specific industry that the company operates in, as this will help you to understand the challenges and opportunities that the company faces.

- Visit the company’s website to learn about their culture and values.

- Read online reviews to get a sense of what it is like to work there.

- Learn about the specific industry that the company operates in.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked during your interview for a Sugar Boiler position. These questions include:

- Tell me about your experience with sugar boiling.

- What are your strengths and weaknesses as a Sugar Boiler?

- Why are you interested in this position?

- What are your salary expectations?

It is important to practice answering these questions in advance so that you can deliver clear and concise answers during your interview. You can practice answering these questions with a friend or family member, or you can record yourself answering the questions and then listen back to your answers to identify areas for improvement.

3. Be prepared to talk about your experience

During your interview, you will be asked about your experience as a Sugar Boiler. Be prepared to talk about your experience in detail, including your responsibilities, your accomplishments, and the challenges you have faced. You should also be prepared to talk about your skills and how they would benefit the company. It is helpful to use specific examples from your experience to illustrate your skills and accomplishments.

4. Dress professionally and arrive on time

It is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time. You should also be polite and respectful to everyone you meet during your interview, including the receptionist, the interviewer, and other employees.

- Dress professionally.

- Arrive on time.

- Be polite and respectful to everyone you meet.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sugar Boiler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sugar Boiler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.