Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sugar Chipper Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sugar Chipper Machine Operator so you can tailor your answers to impress potential employers.

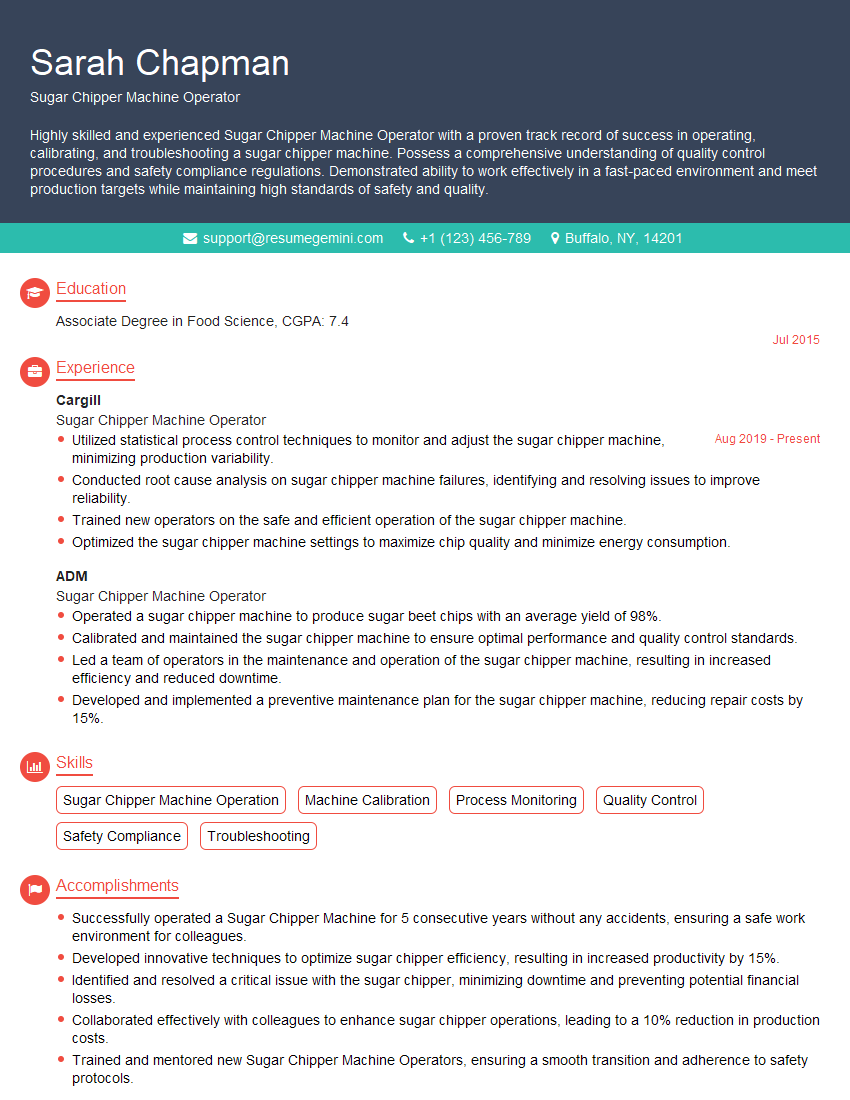

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sugar Chipper Machine Operator

1. What are the key responsibilities of a Sugar Chipper Machine Operator?

The primary responsibilities of a Sugar Chipper Machine Operator typically include:

- Operating and maintaining sugar chipper machines to produce sugar chips from sugarcane.

- Monitoring and adjusting machine settings to ensure optimal performance and chip quality.

- Inspecting and maintaining the machine for smooth functioning and identifying any potential issues.

2. Can you describe the process of operating a Sugar Chipper Machine?

The process of operating a Sugar Chipper Machine generally involves the following steps:

Receiving and preparing sugarcane:

- Receiving and inspecting sugarcane to ensure it meets quality standards.

- Preparing the sugarcane by removing any leaves or debris that may interfere with the chipping process.

Chipping the sugarcane:

- Feeding the sugarcane into the chipper machine’s hopper.

- Monitoring the chipping process to ensure the desired chip size and quality are achieved.

Conveying and storing the sugar chips:

- Conveying the sugar chips away from the chipper machine using a conveyor belt or other means.

- Storing the sugar chips in designated areas for further processing or transportation.

3. What are the different types of Sugar Chipper Machines?

Sugar Chipper Machines can be categorized into various types based on their design, capacity, and application. Some common types include:

- Hammer mills: These machines use rotating hammers to break down sugarcane into smaller pieces.

- Disc chippers: These machines employ rotating discs with sharp blades to cut and chip sugarcane.

- Knifer chippers: These machines utilize fixed or rotating knives to slice and chip sugarcane.

4. What are the common maintenance tasks required for Sugar Chipper Machines?

Regular maintenance is essential to ensure the optimal performance and longevity of Sugar Chipper Machines. Common maintenance tasks include:

- Cleaning and inspecting the machine’s components, such as the blades, hammers, and conveyor belts.

- Lubricating moving parts to reduce friction and wear.

- Checking and adjusting belts, chains, and other mechanical components for proper tension and alignment.

- Identifying and replacing worn or damaged parts promptly.

5. How do you troubleshoot common problems that may arise during the operation of a Sugar Chipper Machine?

To ensure smooth operation, it is important to be able to troubleshoot common problems that may arise during the operation of a Sugar Chipper Machine. Some common issues and their potential solutions include:

- Reduced chipping efficiency: This can be caused by dull blades or hammers. The solution is to sharpen or replace the cutting components.

- Blockages in the conveyor system: This can be caused by foreign objects or excessive sugarcane feed. The solution is to clear the blockage and adjust the feed rate.

- Excessive vibration: This can be caused by unbalanced components or loose bolts. The solution is to balance the components and tighten any loose fasteners.

6. What safety precautions should be taken when operating a Sugar Chipper Machine?

To ensure a safe working environment, it is crucial to adhere to the following safety precautions when operating a Sugar Chipper Machine:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves.

- Follow proper lockout/tagout procedures before performing any maintenance or repairs.

- Keep the work area clean and free of debris to prevent slips and falls.

- Be aware of the machine’s moving parts and keep a safe distance.

- Never attempt to operate the machine if you are not properly trained.

7. What quality control measures are implemented to ensure the production of high-quality sugar chips?

To ensure the production of high-quality sugar chips, the following quality control measures are typically implemented:

- Regular inspection of sugarcane to ensure it meets the required standards.

- Calibration and monitoring of the Sugar Chipper Machine to maintain optimal chipping parameters.

- Sampling and testing of sugar chips to assess their size, shape, and moisture content.

- Implementation of quality control protocols to identify and correct any deviations from the desired specifications.

8. How do you maintain a clean and sanitary work environment in the sugar chipper machine operating area?

Maintaining a clean and sanitary work environment in the sugar chipper machine operating area is essential to ensure the health and safety of workers and the quality of the produced sugar chips. The following practices are typically followed:

- Regular cleaning and disinfection of the machine and its surroundings.

- Proper disposal of sugarcane waste and debris.

- Control of pests and rodents to prevent contamination.

- Implementation of good personal hygiene practices among workers.

- Regular monitoring and maintenance of the work environment to ensure compliance with safety and sanitation standards.

9. What is your experience in optimizing the performance of a Sugar Chipper Machine?

To maximize the efficiency and productivity of a Sugar Chipper Machine, the following optimization techniques can be employed:

- Regular maintenance and calibration to ensure optimal operating conditions.

- Fine-tuning of machine settings to achieve the desired chip size and quality.

- Maximizing the feed rate while maintaining chip quality to increase throughput.

- Minimizing downtime through proactive maintenance and prompt troubleshooting.

- Training operators on best practices for efficient machine operation.

10. Can you describe a challenging situation you encountered while operating a Sugar Chipper Machine and how you overcame it?

During my experience as a Sugar Chipper Machine Operator, I encountered a situation where the machine experienced a sudden vibration and loss of efficiency. To resolve this issue, I followed these steps:

Troubleshooting the issue:

- Visually inspected the machine for any loose or damaged components.

- Checked the alignment and tension of belts and chains.

- Listened for any unusual noises or vibrations that could indicate a specific problem.

Resolving the issue:

- Tightened a loose bolt that was causing the vibration.

- Adjusted the tension of a belt that was slipping.

- Replaced a worn bearing that was causing excessive noise.

After implementing these corrective actions, the machine’s performance was restored, and it operated smoothly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sugar Chipper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sugar Chipper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sugar Chipper Machine Operators are responsible for the safe and efficient operation of sugar chipping machines in a food processing environment. They ensure that the machine is clean, calibrated, and functioning properly to produce high-quality sugar chips.

1. Machine Operation

Operate sugar chipping machines according to established procedures and safety guidelines.

- Load sugar beets into the machine.

- Monitor machine performance and make adjustments as needed.

2. Quality Control

Inspect sugar chips for quality and consistency.

- Check chip size, color, and texture.

- Identify and remove any foreign objects.

3. Maintenance

Perform routine maintenance on sugar chipping machines.

- Clean and lubricate machine components.

- Identify and repair minor malfunctions.

4. Safety

Adhere to all safety regulations and procedures.

- Wear appropriate personal protective equipment.

- Follow lockout/tagout procedures.

Interview Tips

Preparation is key to acing any interview. Here are some specific tips for Sugar Chipper Machine Operator interviews:

1. Research the Company and Industry

Learn about the company’s history, products, and market position. This will help you understand the company’s culture and goals, and how your skills and experience can contribute to their success.

- Visit the company’s website.

- Read industry news articles.

- Attend industry events.

2. Practice Your Answers

Think about common interview questions and prepare your answers. This will help you feel confident and articulate during the interview.

- Tell me about your experience with sugar chipping machines.

- What are your strengths and weaknesses as a Sugar Chipper Machine Operator?

- Why are you interested in this position?

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This shows that you are taking the interview seriously and that you respect the interviewer’s time.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose shoes that are comfortable and professional.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic about their work and who are positive about their abilities. Show the interviewer that you are excited about the opportunity to work for their company.

- Smile and make eye contact.

- Speak clearly and confidently.

- Be honest and upfront about your skills and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sugar Chipper Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.