Feeling lost in a sea of interview questions? Landed that dream interview for Sugar Refiner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sugar Refiner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

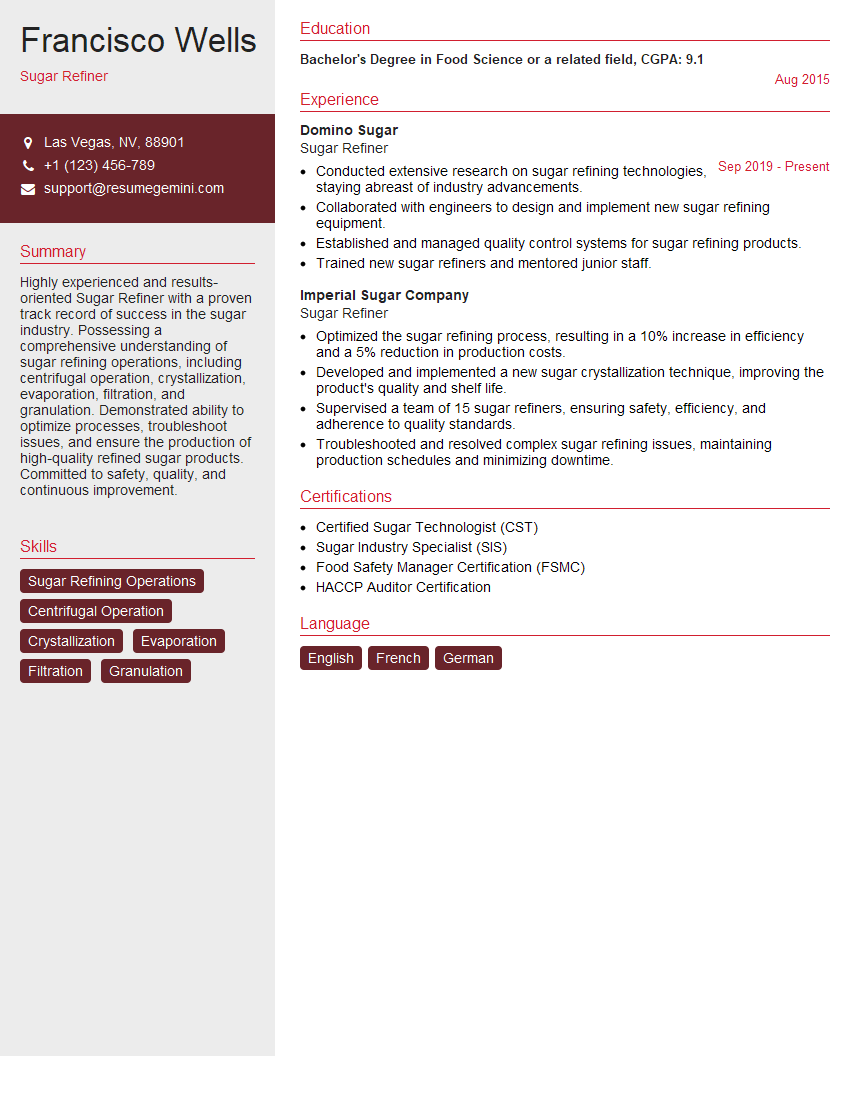

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sugar Refiner

1. What are the key performance indicators (KPIs) you typically monitor in a sugar refining operation?

KPIs may include:

- Extraction efficiency

- Refining loss

- Purity of finished product

- Yield of refined sugar

- Quality control parameters (e.g., color, moisture content, particle size)

2. Describe the different stages involved in the sugar refining process.

Raw Sugar Cleaning

- Removing impurities (e.g., dirt, stones, leaves)

- Dissolving sugar in water to form a liquor

Liquor Purification

- Treating liquor with lime and carbon dioxide to remove impurities

- Filtration and clarification

Crystallization

- Evaporating liquor to supersaturate the sugar

- Cooling and introducing seed crystals to induce crystallization

Centrifugation

- Separating sugar crystals from molasses

- Washing and drying crystals

3. Discuss the equipment used in modern sugar refining plants.

Equipment typically includes:

- Cane crushers and shredders

- Extraction diffusers

- Clarifiers

- Filters

- Crystallizers

- Centrifuges

- Dryers

- Packaging machines

4. What are the common challenges encountered in sugar refining and how can they be mitigated?

Challenges and mitigation strategies:

- Impurities: Implement effective cleaning and purification processes.

- Color formation: Use decolorizing agents or optimize process conditions.

- Crystallization issues: Control temperature, agitation, and nucleation rate.

- Equipment downtime: Conduct regular maintenance and implement redundancy plans.

- Product quality variations: Establish robust quality control systems.

5. How do you ensure the safety and quality of sugar products?

Ensuring safety and quality involves:

- Implementing food safety management systems (e.g., HACCP, ISO 22000)

- Complying with regulatory standards and best practices

- Conducting regular testing and inspections

- Training employees on food safety and quality control

- Establishing quality control specifications and monitoring processes

6. What are the key trends and advancements in the sugar refining industry?

Key trends and advancements:

- Automation and digitization: Implementing sensors, control systems, and data analytics.

- Sustainability: Reducing water and energy consumption, and minimizing waste.

- Alternative sweeteners: Exploring natural and artificial sweeteners as substitutes for refined sugar.

- Research and development: Developing new technologies for improved extraction and refining efficiency.

- Product diversification: Expanding into value-added products (e.g., specialty sugars, syrups, sweeteners blends).

7. How do you optimize the extraction process in sugar refining?

Extraction optimization strategies:

- Cane preparation: Cutting and crushing cane efficiently to expose sucrose.

- Diffusion process: Using high-efficiency diffusers to leach sucrose from cane.

- Temperature and pH control: Optimizing conditions for maximum sucrose extraction.

- Maceration: Adding water to the bagasse to extract residual sucrose.

- Clarification: Removing impurities to improve juice quality.

8. What are the quality control measures applied in sugar refining?

Quality control measures include:

- Raw material inspection: Assessing the quality of incoming cane or beets.

- Process monitoring: Tracking key parameters during extraction, purification, and crystallization.

- Product testing: Analyzing finished products for purity, color, moisture content, and other specifications.

- Sensory evaluation: Taste and appearance testing to ensure product acceptability.

- Compliance audits: Ensuring adherence to regulatory standards and internal quality protocols.

9. How do you handle waste management in a sugar refining plant?

Waste management strategies:

- Bagasse utilization: Using bagasse as fuel, animal feed, or compost.

- Molasses treatment: Converting molasses into ethanol or other byproducts.

- Water recycling: Treating and reusing process water to minimize discharge.

- Emissions control: Implementing technologies to reduce air and water pollution.

10. What are the safety precautions that must be observed in a sugar refining plant?

Safety precautions include:

- Machine guarding: Installing barriers around moving machinery.

- Hazard communication: Providing clear instructions and labels for potential hazards.

- Personal protective equipment: Requiring employees to wear appropriate gear.

- Emergency response plans: Establishing protocols for fires, spills, and other emergencies.

- Training and education: Informing employees about safety procedures and hazardous materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sugar Refiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sugar Refiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sugar Refiners play a crucial role in the production of refined sugar, a widely consumed sweetener used in various industries and households. They are responsible for a range of tasks that ensure the quality and purity of refined sugar.

1. Raw Sugar Processing

Sugar Refiners begin by processing raw sugar, which is typically imported from sugar-producing countries. This involves:

- Melting raw sugar to dissolve impurities

- Filtering out suspended solids and impurities

- Decolorizing the sugar solution using activated carbon

- Crystallizing the sugar from the solution

2. Refining Process

Once raw sugar has been processed, it undergoes further refining steps to remove remaining impurities and enhance its quality:

- Recrystallizing the sugar to obtain larger, more uniform crystals

- Dissolving and recrystallizing the sugar to remove residual impurities

- Centrifuging the sugar to separate crystals from syrup

- Drying the sugar crystals to remove moisture

3. Packaging and Storage

Refined sugar is packaged in various forms, including granulated, cube, and liquid, to meet customer requirements:

- Packaging sugar in bags, cartons, or bulk containers

- Labeling and storing sugar according to industry standards

- Maintaining inventory and ensuring proper storage conditions

4. Quality Control and Safety

Sugar Refiners are responsible for maintaining the highest quality standards and ensuring the safety of the refined sugar:

- Conducting regular quality checks on raw materials and finished products

- Monitoring the refining process to ensure efficiency and consistency

- Adhering to safety protocols and regulations

- Maintaining a clean and hygienic work environment

Interview Tips

Preparing thoroughly for a Sugar Refiner interview is essential to showcase your qualifications and increase your chances of success. Here are some tips to guide you:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry position, and specific role requirements. Researching their website, news articles, and social media profiles will provide you with valuable insights.

2. Highlight Relevant Experience and Skills

Emphasize your technical knowledge, experience in sugar refining or a related field, and any relevant certifications or licenses. Quantify your accomplishments and provide specific examples of your contributions in previous roles.

3. Demonstrate Your Understanding of the Industry

Showcase your understanding of the sugar refining industry, including recent trends, market dynamics, and technological advancements. This demonstrates your industry knowledge and adaptability.

4. Prepare for Technical Questions

Anticipate questions related to the sugar refining process, equipment operation, and quality control procedures. Familiarize yourself with the terminology and concepts associated with the role.

5. Emphasize Your Safety and Quality Focus

Highlight your commitment to safety and quality assurance. Describe your experience with maintaining a clean and safe work environment, adhering to industry regulations, and implementing quality control measures.

6. Practice Your Communication Skills

Articulate your thoughts clearly and concisely. Practice answering questions in a structured and professional manner. Use examples and data to support your responses.

7. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the role and the company. Prepare questions about the company’s growth plans, industry outlook, or opportunities for professional development.

8. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time. A professional demeanor reflects your respect for the company and the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sugar Refiner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sugar Refiner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.