Are you gearing up for a career in Supplier Quality Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Supplier Quality Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

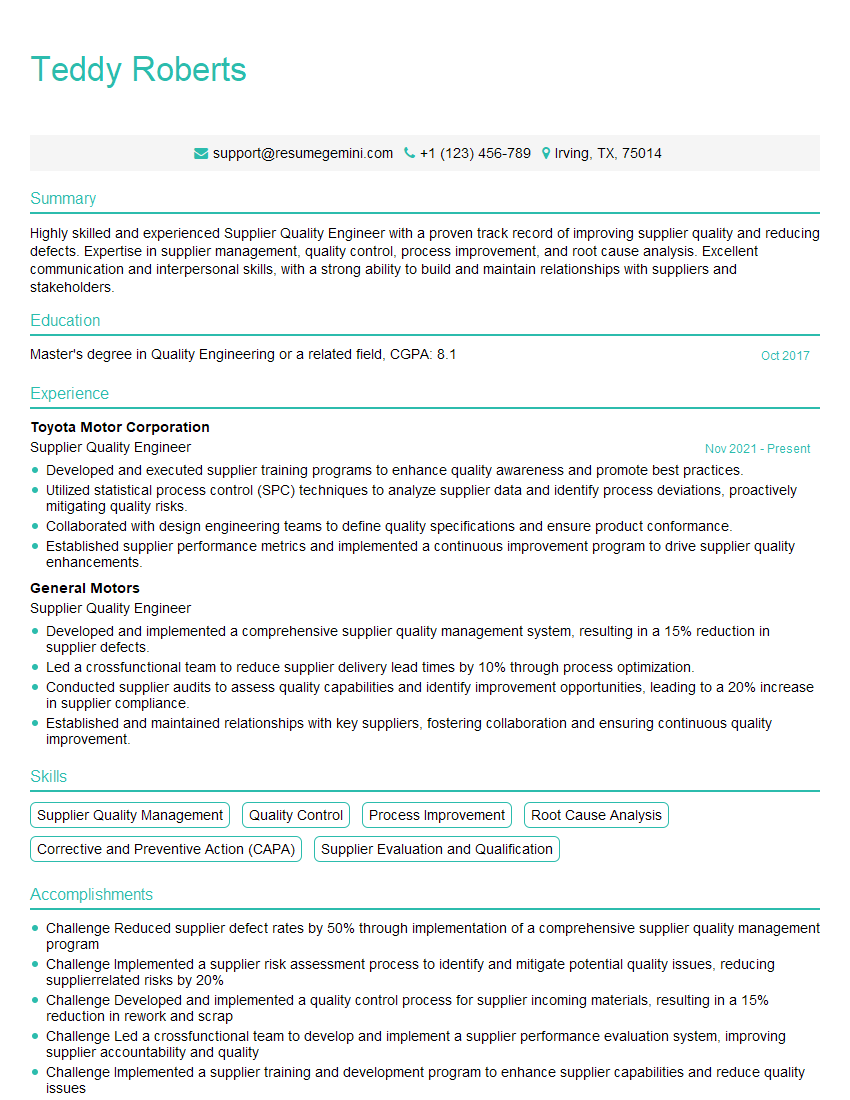

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Supplier Quality Engineer

1. How would you approach the task of evaluating a new supplier for a critical component?

- Review the supplier’s quality management system (QMS) to ensure it aligns with the industry standards and company requirements.

- Conduct a supplier audit to assess their manufacturing capabilities, quality processes, and production environment.

- Analyze the supplier’s performance history, including their on-time delivery, defect rates, and customer feedback.

- Assess the supplier’s financial stability, reputation, and overall risk profile.

- Conduct a risk assessment to identify potential risks associated with sourcing from the supplier, such as supply chain disruptions or quality issues.

2. What are the key elements of an effective supplier quality management program?

Establish clear quality expectations

- Develop and communicate supplier quality specifications, standards, and requirements.

- Establish performance metrics to monitor supplier quality and identify areas for improvement.

Supplier evaluation and selection

- Implement a robust supplier evaluation process to assess potential suppliers’ capabilities and quality systems.

- Select suppliers based on their quality performance, reliability, and ability to meet the company’s requirements.

Supplier monitoring and continuous improvement

- Regularly monitor supplier performance against established metrics.

- Conduct supplier audits to assess their ongoing compliance and identify opportunities for improvement.

- Provide feedback and support to suppliers to help them enhance their quality processes and products.

3. What tools and techniques do you use to analyze supplier performance data?

- Statistical process control (SPC) charts to monitor process stability and identify trends.

- Pareto analysis to identify the root causes of quality issues and prioritize corrective actions.

- Failure mode and effects analysis (FMEA) to assess potential failure modes and their impact on the product or process.

- Benchmarking against industry standards and best practices to identify areas for improvement.

- Data visualization tools to present performance data in a clear and actionable way.

4. How do you handle situations where a supplier fails to meet quality expectations?

- Communicate the quality issue to the supplier and request a corrective action plan.

- Investigate the root cause of the issue and identify measures to prevent it from recurring.

- Monitor the supplier’s corrective actions and provide support as needed.

- If the supplier is unable to resolve the quality issue, evaluate alternative sourcing options.

- Document the entire process and maintain open communication with all stakeholders.

5. What is your experience with supplier development programs?

- Assessed supplier capabilities and identified areas for improvement.

- Developed and implemented training programs to enhance supplier quality processes.

- Provided technical assistance and guidance to suppliers to help them meet the company’s quality standards.

- Monitored supplier progress and provided ongoing support to ensure continuous improvement.

- Recognized and rewarded suppliers for their efforts and achievements in improving quality.

6. How do you stay up-to-date on the latest quality management trends and best practices?

- Attend industry conferences and workshops.

- Read professional journals and articles.

- Participate in online forums and discussion groups.

- Network with other quality professionals.

- Complete continuing education courses and certifications.

7. What is your understanding of Six Sigma and lean manufacturing principles?

- Six Sigma: A data-driven approach to improving processes and reducing defects by identifying and eliminating variation

- Lean manufacturing: A philosophy that focuses on eliminating waste and improving efficiency throughout the supply chain

8. How would you approach the task of implementing a quality management system in a new organization?

- Conduct a needs assessment to identify the organization’s specific requirements.

- Develop a quality policy and objectives that align with the organization’s strategic goals.

- Establish a quality management structure and assign responsibilities.

- Implement quality processes and procedures throughout the organization.

- Provide training and support to employees to ensure they understand and follow the quality management system.

- Monitor the effectiveness of the quality management system and make adjustments as needed.

- Continuously improve the quality management system to enhance its effectiveness.

9. What are the challenges you have faced in your previous roles as a Supplier Quality Engineer?

- Dealing with suppliers who have different quality standards and expectations.

- Balancing the need for supplier development with the need to maintain high-quality standards.

- Convincing suppliers to invest in quality improvements that may not have an immediate return on investment.

- Working with cross-functional teams to ensure that quality is considered in all aspects of the supply chain.

10. What are your career goals and how does this role align with them?

- To continue to grow my skills and knowledge in the field of supplier quality management.

- To make a significant contribution to the success of my organization by ensuring that we receive high-quality products and services from our suppliers.

- To eventually lead a team of supplier quality engineers and develop a world-class supplier quality program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Supplier Quality Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Supplier Quality Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supplier Quality Engineers are responsible for developing and implementing quality assurance programs for suppliers. They work with suppliers to ensure that they are meeting all of the company’s quality standards. They may also be responsible for conducting quality audits and inspections.

1. Develop and implement quality assurance programs

Supplier Quality Engineers develop and implement quality assurance programs for suppliers. These programs are designed to ensure that suppliers are meeting all of the company’s quality standards. They may also be responsible for conducting quality audits and inspections.

- Develop quality assurance plans and procedures.

- Implement quality assurance programs.

- Conduct quality audits and inspections.

2. Work with suppliers to ensure they are meeting all of the company’s quality standards

Supplier Quality Engineers work with suppliers to ensure that they are meeting all of the company’s quality standards. They may provide training, technical assistance, and support to suppliers. They may also work with suppliers to develop and implement quality improvement plans.

- Work with suppliers to develop and implement quality improvement plans.

- Provide training, technical assistance, and support to suppliers.

- Monitor supplier performance and provide feedback.

3. Conduct quality audits and inspections

Supplier Quality Engineers may be responsible for conducting quality audits and inspections. These audits and inspections are designed to ensure that suppliers are meeting all of the company’s quality standards. They may also be responsible for investigating and resolving quality issues.

- Conduct quality audits and inspections.

- Investigate and resolve quality issues.

- Generate and maintain quality records.

4. Stay up-to-date on the latest quality standards and best practices

Supplier Quality Engineers must stay up-to-date on the latest quality standards and best practices. They may do this by attending conferences, reading industry publications, or taking online courses.

- Attend conferences.

- Read industry publications.

- Take online courses.

Interview Tips

Here are some tips to help you ace your Supplier Quality Engineer interview:

1. Research the company and the position

Before you go on your interview, research the company and the position you are applying for. This will help you understand the company’s culture and the qualifications they are looking for in a Supplier Quality Engineer.

- Visit the company’s website.

- Read industry publications.

- Talk to people who work at the company.

2. Prepare your answers to common interview questions

There are some common interview questions that you can prepare for in advance. These questions may include:

- Tell me about your experience in Supplier Quality Engineering.

- What are your strengths and weaknesses?

- Why are you interested in this position?

3. Be prepared to talk about your experience and skills

During your interview, you will be asked to talk about your experience and skills. Be prepared to give specific examples of your work. You should also be able to explain how your skills and experience can benefit the company.

- Give specific examples of your work.

- Explain how your skills and experience can benefit the company.

- Be prepared to answer questions about your experience and skills.

4. Be confident and enthusiastic

Confidence and enthusiasm are important qualities for a Supplier Quality Engineer. Be confident in your abilities and enthusiastic about the position you are applying for. This will help you make a good impression on the interviewer.

- Be confident in your abilities.

- Be enthusiastic about the position you are applying for.

- Make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Supplier Quality Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.