Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Supply Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

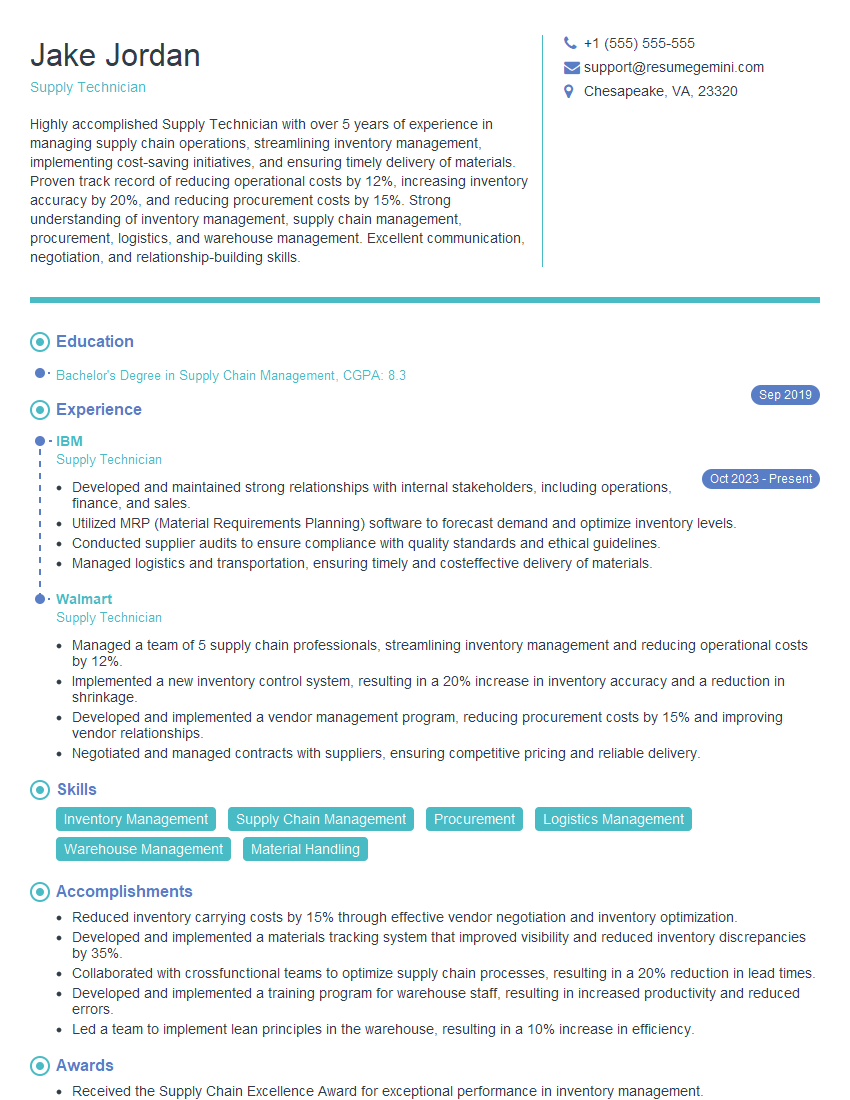

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Supply Technician

1. Describe the process of receiving and inspecting incoming supplies?

The process of receiving and inspecting incoming supplies typically involves the following steps:

- Verifying the delivery: Checking the delivery against the purchase order to ensure that the correct items and quantities have been received.

- Inspecting the items: Examining the items for any damage, defects, or other issues.

- Documenting the inspection: Recording the results of the inspection, including any discrepancies or issues found.

- Storing the items: Placing the items in the appropriate storage location.

2. What techniques do you use to ensure accurate inventory management?

Inventory Control System

- Using a computerized inventory control system to track inventory levels and manage stock.

- Conducting regular inventory audits to verify the accuracy of the inventory records.

Cycle Counting

- Implementing cycle counting procedures to identify and correct inventory discrepancies.

- Utilizing inventory scanning technology to improve the accuracy of inventory counts.

3. How do you manage the procurement process for supplies?

I manage the procurement process for supplies by following these key steps:

- Identifying and qualifying suppliers: Researching and evaluating potential suppliers to ensure they meet quality and reliability standards.

- Requesting and evaluating quotes: Soliciting quotes from qualified suppliers and comparing them based on price, quality, and delivery time.

- Negotiating and placing orders: Negotiating the best terms with suppliers and placing orders for the required supplies.

- Tracking and expediting orders: Monitoring the status of orders and taking proactive steps to expedite delivery if necessary.

- Receiving and inspecting goods: Ensuring that the goods received meet the specifications and quality standards.

4. How do you stay up-to-date on the latest supply chain management trends and best practices?

I stay up-to-date on the latest supply chain management trends and best practices through the following methods:

- Attending industry conferences and webinars: Participating in industry events to learn about new technologies, strategies, and trends.

- Reading industry publications and online resources: Subscribing to trade magazines, journals, and online platforms to gain insights from experts and thought leaders.

- Networking with other supply chain professionals: Connecting with peers and colleagues to exchange ideas and learn about innovative approaches.

- Pursuing professional development opportunities: Taking courses, workshops, or certifications to enhance my skills and knowledge.

5. Describe your experience in managing inventory in a fast-paced environment.

In my previous role at XYZ Company, I was responsible for managing inventory in a fast-paced manufacturing environment. The company specialized in producing high-volume, time-sensitive products. To effectively manage inventory in this demanding setting, I implemented the following strategies:

- Established a robust inventory management system: I implemented a computerized inventory system to track inventory levels, forecast demand, and optimize stock levels.

- Implemented cycle counting procedures: I introduced regular cycle counting processes to identify and correct inventory discrepancies promptly.

- Collaborated with suppliers: I worked closely with suppliers to establish reliable delivery schedules and ensure timely replenishment of critical items.

- Trained staff on inventory management best practices: I provided comprehensive training to warehouse staff on proper inventory handling, storage, and documentation procedures.

6. How do you ensure the quality of supplies and materials?

To ensure the quality of supplies and materials, I follow a rigorous quality control process:

- Establish quality standards: I work with stakeholders to define clear quality standards for all incoming supplies and materials.

- Supplier evaluation: I conduct thorough supplier evaluations to assess their quality management systems and track their performance over time.

- Incoming inspection: I implement a comprehensive incoming inspection process to verify that supplies and materials meet the established quality standards.

- Vendor management: I maintain open communication with suppliers to address any quality issues promptly and develop corrective action plans.

7. How do you handle and resolve supply chain disruptions?

To effectively handle and resolve supply chain disruptions, I follow these key steps:

- Early identification: I continuously monitor supply chain performance indicators and maintain strong relationships with suppliers to identify potential disruptions early on.

- Risk assessment: I conduct thorough risk assessments to evaluate the potential impact of disruptions and develop contingency plans.

- Contingency planning: I implement contingency plans, such as diversifying suppliers, maintaining safety stock, and establishing alternative transportation routes.

- Collaboration and communication: I work closely with suppliers, customers, and internal stakeholders to mitigate disruptions and communicate potential impacts.

8. How do you measure and evaluate the performance of supply chain operations?

To effectively measure and evaluate the performance of supply chain operations, I utilize a combination of metrics and key performance indicators (KPIs):

- Order fulfillment rate: I track the percentage of orders that are fulfilled on time and in full.

- Inventory turnover: I monitor inventory turnover to assess the efficiency of inventory management.

- Supply chain costs: I analyze supply chain costs, including transportation, warehousing, and inventory carrying costs.

- Supplier performance: I evaluate supplier performance based on factors such as delivery reliability, product quality, and responsiveness.

9. What is your experience in using technology to improve supply chain management?

Over the course of my career, I have gained significant experience in leveraging technology to improve supply chain management:

- Inventory management systems: I have implemented and managed various inventory management systems to streamline inventory tracking, forecasting, and replenishment.

- Supply chain planning tools: I have utilized supply chain planning tools to optimize inventory levels, reduce lead times, and enhance supply chain visibility.

- Transportation management systems: I have employed transportation management systems to optimize shipping routes, reduce freight costs, and improve delivery efficiency.

- Data analytics: I have applied data analytics techniques to identify supply chain trends, predict demand, and make informed decisions.

10. How do you stay up-to-date on the latest advancements in supply chain management?

To ensure that I remain knowledgeable about the latest advancements in supply chain management, I actively engage in the following practices:

- Industry conferences and webinars: I attend industry conferences and webinars to gain insights from experts and learn about emerging trends.

- Professional development: I pursue professional development opportunities, such as certifications and workshops, to expand my knowledge and skills.

- Research and reading: I regularly read industry publications, research papers, and online resources to stay informed about the latest advancements in the field.

- Networking: I connect with other supply chain professionals through networking events and online platforms to exchange ideas and learn about new technologies and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Supply Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Supply Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supply Technicians play a vital role in ensuring the smooth functioning of organizations by managing the procurement, storage, and distribution of materials and supplies.

1. Inventory Management

Maintaining accurate inventory records, including tracking stock levels and identifying potential shortages or surpluses.

- Using inventory management software to streamline processes.

- Conducting physical inventory counts to ensure accuracy.

2. Procurement and Ordering

Identifying and acquiring necessary supplies from approved vendors, ensuring timely delivery and cost-effectiveness.

- Negotiating contracts with suppliers.

- Processing purchase orders and tracking delivery status.

3. Receiving and Inspection

Inspecting incoming shipments for quality and compliance, ensuring they meet specifications.

- Verifying quantities and condition of received items.

- Documenting any discrepancies or damages.

4. Shipping and Delivery

Preparing and shipping orders to customers or internal departments, ensuring timely and accurate delivery.

- Packing and labeling shipments.

- Coordinating with carriers for delivery logistics.

5. Warehouse Management

Maintaining an organized and efficient warehouse environment, ensuring proper storage and retrieval of materials.

- Establishing and adhering to warehouse layout and storage procedures.

- Using forklifts or other equipment for material handling.

Interview Tips

To prepare for your Supply Technician interview, it’s essential to highlight your skills, experience, and knowledge relevant to the job. Consider the following tips:

1. Research the Organization

Learn about the organization’s industry, products or services, and supply chain operations. This demonstrates your interest and ability to align with their goals.

- Visit the company website and LinkedIn page.

- Read industry news and articles related to the organization.

2. Highlight Relevant Skills and Experience

Emphasize your knowledge of inventory management, procurement, warehouse operations, and other supply chain functions. Quantify your accomplishments whenever possible.

- Provide specific examples of your involvement in inventory control or procurement projects.

- Describe how you improved efficiency or reduced costs in previous roles.

3. Prepare for Technical Questions

Anticipate questions about inventory management techniques, procurement processes, and warehouse operations. Demonstrate your understanding of the latest industry best practices and technologies.

- Review inventory management systems like FIFO and LIFO.

- Be familiar with procurement methods such as vendor selection and contract negotiation.

4. Practice Active Listening

During the interview, pay close attention to the interviewer’s questions and verbally acknowledge their points. Ask clarifying questions to ensure you understand their requirements.

- Use phrases like “I understand” or “Can you please elaborate on that?”

- Summarize the main points of the interviewer’s questions to demonstrate your comprehension.

5. Prepare Thoughtful Questions

At the end of the interview, ask thoughtful questions that show your interest in the role and the organization. This could include asking about their supply chain strategies or career development opportunities.

- Inquire about the company’s plans for inventory optimization or warehouse automation.

- Ask about opportunities for professional growth and training within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Supply Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!