Are you gearing up for a career in Surfacer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Surfacer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

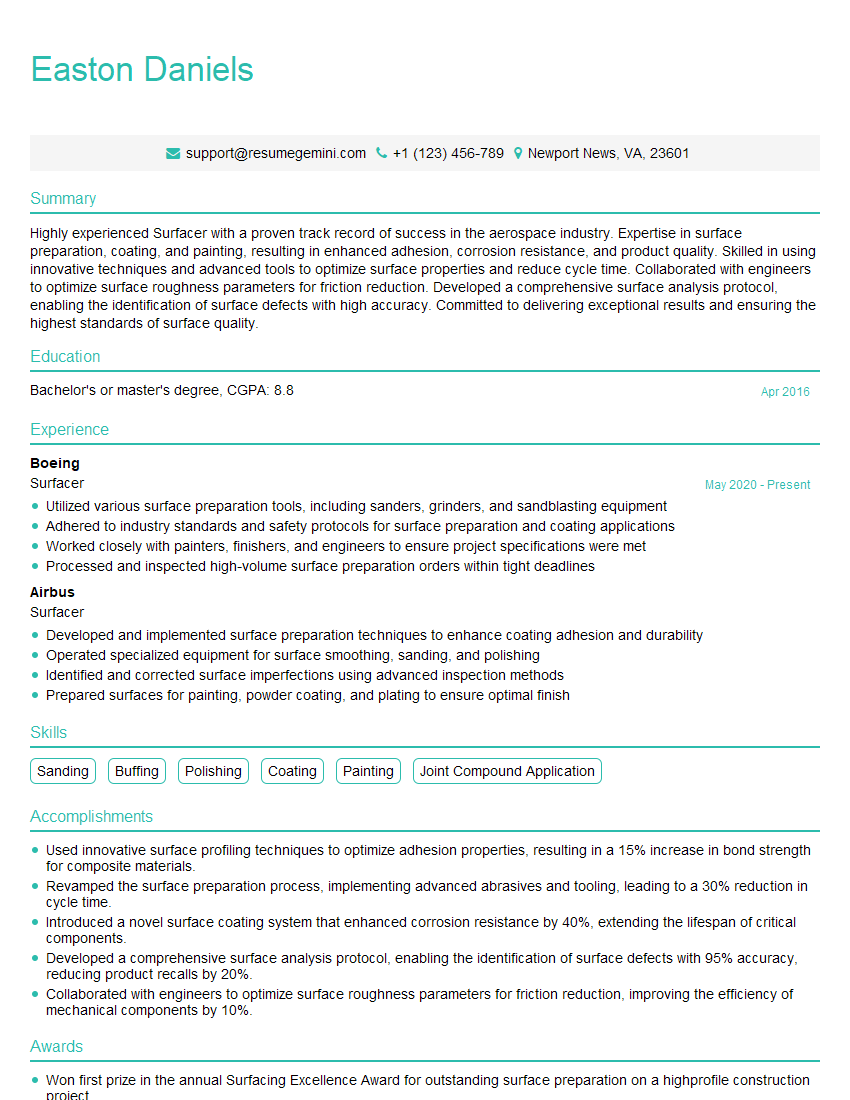

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Surfacer

1. Explain the different methods of surface preparation for various materials?

- Mechanical Methods: These methods involve the use of abrasive tools or materials to remove contaminants and create a rough surface for better adhesion, such as sanding, grinding, and shot blasting.

- Chemical Methods: These methods use chemical solutions or solvents to dissolve or remove contaminants and prepare the surface for coating or adhesion, such as degreasing, etching, and pickling.

- Thermal Methods: These methods apply heat to the surface to change its properties or remove contaminants, such as flame treatment and plasma cleaning.

2. What are the factors to consider when selecting a surface preparation method?

- Material Type: Different materials require different preparation methods based on their properties, such as hardness, porosity, and reactivity.

- Adhesion Requirement: The level of adhesion required for the subsequent process (e.g., coating, bonding) influences the choice of preparation method.

- Environmental Regulations: Certain preparation methods may release hazardous substances or generate waste, which must be considered in compliance with environmental regulations.

- Cost and Efficiency: The cost and efficiency of the preparation method should be evaluated based on factors like time, material consumption, and equipment availability.

3. Describe the process of applying a protective coating to a metal surface, including the steps involved?

- Surface Preparation: Cleaning and preparing the metal surface to ensure proper adhesion of the coating.

- Coating Selection: Choosing the appropriate coating based on the desired properties, such as corrosion resistance, chemical resistance, and mechanical strength.

- Application: Applying the coating using methods like spraying, brushing, or dipping, and ensuring proper thickness and coverage.

- Curing: Allowing the coating to cure through heat, chemical reactions, or other processes to achieve its final properties.

- Inspection and Testing: Evaluating the coating’s adhesion, thickness, and overall performance to ensure quality and effectiveness.

4. What are the common defects that can occur during surface preparation and coating?

- Inadequate Surface Preparation: Incomplete removal of contaminants or improper surface profile, leading to poor adhesion.

- Improper Coating Application: Uneven thickness, runs, or missed spots, affecting the coating’s performance.

- Insufficient Curing: Incomplete or improper curing, resulting in weak or ineffective coatings.

- Contamination: Presence of foreign particles or contaminants on the surface, affecting adhesion and coating integrity.

- Environmental Factors: Exposure to moisture, temperature extremes, or other environmental conditions can damage the coating or hinder its performance.

5. What are the latest advancements in surface preparation and coating technologies?

- Laser Surface Treatment: Using lasers to modify the surface properties of materials for improved corrosion resistance, wear resistance, and biocompatibility.

- Plasma Spraying: Applying coatings using plasma technology, resulting in high bond strength, durability, and resistance to wear and corrosion.

- Thermal Spraying: Depositing coatings with high temperature processes, offering excellent wear resistance, thermal insulation, and corrosion protection.

- Nanotechnology: Utilizing nanomaterials to create coatings with enhanced properties, such as self-cleaning, antimicrobial, and ultra-hardness.

- Environmentally Friendly Coatings: Developing coatings with low VOCs, water-based formulations, and reduced environmental impact.

6. What are the challenges and best practices associated with surface preparation and coating in the automotive industry?

- Challenges: Meeting strict quality standards, handling complex geometries, optimizing coating performance for various materials.

- Best Practices: Implementing rigorous surface preparation protocols, using advanced coating technologies, conducting thorough testing and inspection, and adhering to industry standards.

7. How do you ensure the quality of surface preparation and coatings in your work?

- Following Standard Procedures: Adhering to established protocols for surface preparation and coating application.

- Visual Inspection: Regularly checking the quality of the surface and coating, identifying any defects or imperfections.

- Performance Testing: Conducting tests to verify the coating’s adhesion, durability, and resistance to wear, corrosion, or other factors.

- Continuous Improvement: Seeking feedback, analyzing results, and implementing improvements to enhance quality.

8. How do you handle situations where surface preparation or coating issues arise?

- Troubleshooting: Identifying the root cause of the issue and implementing corrective actions.

- Re-preparation and Coating: If necessary, re-preparing the surface and re-applying the coating to ensure proper adhesion and performance.

- Communication: Informing relevant parties about the issue and collaborating to find solutions.

9. Describe your knowledge of different surface preparation techniques for plastics.

- Mechanical Abrasion: Using abrasive materials to remove contaminants and create a rough surface, such as sanding, grinding, or blasting.

- Chemical Etching: Using chemicals to dissolve or modify the surface layer of the plastic, improving adhesion and wettability.

- Flame Treatment: Exposing the surface to a flame to alter its chemical composition, increasing surface energy and adhesion.

- Corona Treatment: Utilizing electrical discharge to create a high-energy surface, improving adhesion and coating compatibility.

10. What are the key considerations for selecting the appropriate coating for a given application?

- Substrate Material: The type of surface being coated, its properties, and compatibility with the coating.

- Environmental Conditions: The exposure to weather, chemicals, temperature, and other factors that the coating must withstand.

- Performance Requirements: The desired properties, such as corrosion resistance, wear resistance, electrical insulation, or aesthetics.

- Application Process: The compatibility of the coating with the available application methods, such as spraying, brushing, or dipping.

- Cost and Availability: The financial implications and accessibility of the coating for the specific application.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Surfacer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Surfacer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Surfacers play a crucial role in the construction industry, responsible for preparing and finishing surfaces for painting, tiling, or other treatments. Their key job responsibilities include:

1. Surface Preparation

Surfacers prepare surfaces by removing old paint, wallpaper, or other materials using tools like scrapers, sanders, or power washers. They also patch or repair any cracks, holes, or uneven areas to ensure a smooth and even surface.

2. Drywall Installation and Repair

Installing and repairing drywall is a common task for surfacers. They cut and fit drywall panels, fasten them securely to walls or ceilings, and finish the joints and seams to create a seamless surface.

3. Texturing and Smoothing

Surfacers apply texture or smooth finishes to surfaces based on the desired result. They use sprayers or trowels to create textures like stipple, knockdown, or orange peel. They also sand or scrape surfaces to achieve a smooth finish.

4. Caulking and Sealing

Caulking and sealing are essential tasks to prevent moisture or air penetration, and surfacers are responsible for applying caulk or sealant around windows, doors, pipes, and other openings.

Interview Tips

To ace the interview for a Surfacer position, candidates should prepare thoroughly and consider the following tips:

1. Research the Company and Industry

Research the company’s background, services, and industry trends to demonstrate your interest and understanding of the field.

2. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your skills, experience, and why you’re interested in the role. You can find sample questions online or consult with a career counselor.

3. Highlight Relevant Skills and Experience

Thoroughly review the job description and emphasize how your skills and experience align with the requirements. Quantify your accomplishments whenever possible, using specific examples.

4. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive and enthusiastic attitude throughout the interview. Show the interviewer that you’re genuinely interested in the position and the company.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the role, company culture, and future opportunities. This shows your engagement and interest in the position.

6. Follow Up

After the interview, send a thank-you note to the interviewer, reiterating your interest in the position and expressing your gratitude for their time. Consider briefly summarizing your key qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Surfacer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!