Feeling lost in a sea of interview questions? Landed that dream interview for Surfacing Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Surfacing Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

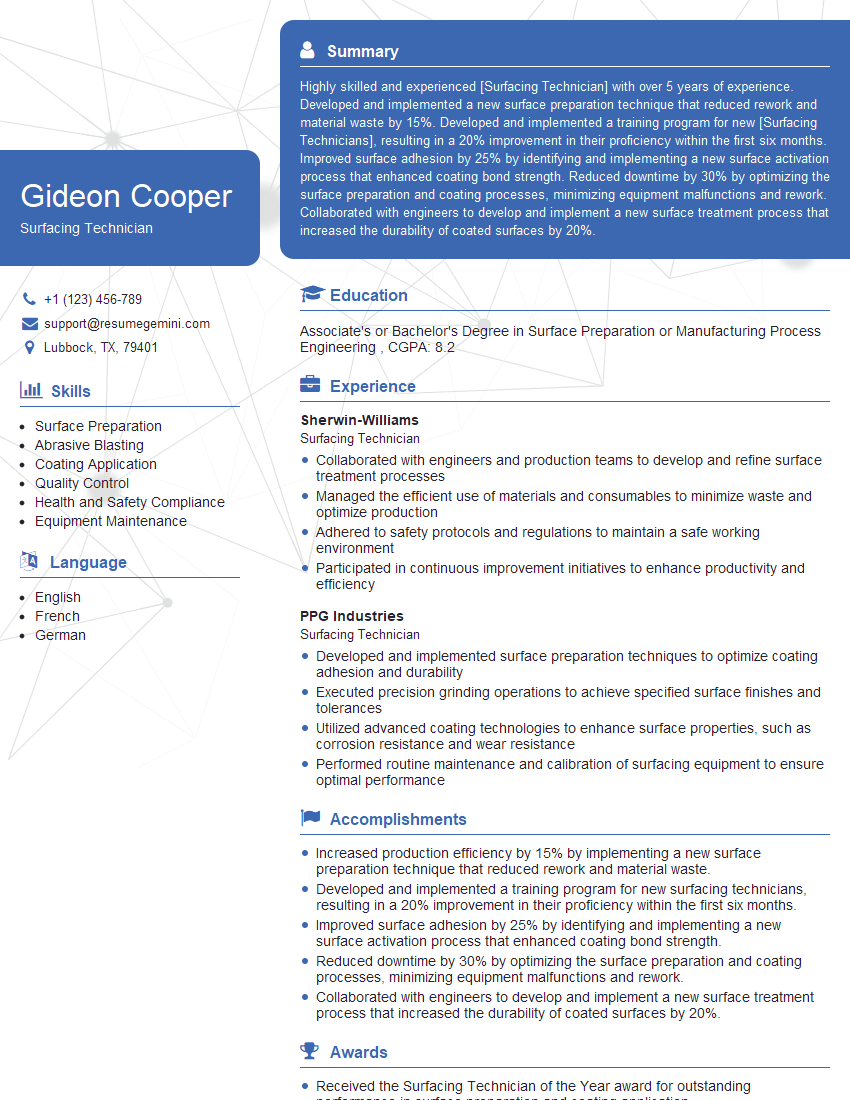

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Surfacing Technician

1. What are the different types of surfacing materials and their applications?

- Asphalt: Used for roads, driveways, and parking lots due to its durability and cost-effectiveness.

- Concrete: Ideal for sidewalks, patios, and foundations because of its strength and resistance to wear and tear.

- Pavers: Available in various materials like brick, stone, and concrete, used for decorative and functional purposes on walkways, patios, and driveways.

- Resin-based surfacing: Used in commercial and industrial settings for flooring and surfaces that require chemical resistance and non-slip properties.

2. Describe the steps involved in preparing a surface for surfacing.

Surface Inspection:

- Check for cracks, unevenness, and any existing damage.

- Determine the type of subsurface and its condition.

Surface Preparation:

- Remove any loose debris or vegetation.

- Repair or fill cracks and holes to ensure a smooth base.

- Apply a primer or bonding agent to enhance adhesion.

3. What factors influence the selection of a surfacing material?

- Intended use: Purpose and traffic load the surface will experience.

- Climate conditions: Temperature fluctuations, precipitation, and UV exposure.

- Aesthetics: Color, texture, and visual appeal considerations.

- Budget and maintenance costs: Installation expenses and long-term upkeep requirements.

- Environmental regulations: Compliance with local codes and sustainability standards.

4. How do you ensure proper compaction and curing of surfaced areas?

- Compaction: Use appropriate equipment, such as rollers or tampers, to achieve the desired density and stability.

- Curing: Allow the surface to rest and cure according to the manufacturer’s guidelines. This involves protecting it from moisture, excessive heat, and traffic.

- Monitoring: Regularly check the surface for any signs of cracking or settling, and make necessary adjustments.

5. What are the potential hazards associated with surfacing work and how do you mitigate them?

- Heavy machinery: Follow proper safety protocols for equipment operation and wear personal protective gear.

- Chemicals: Handle materials like solvents and bonding agents with care, ensuring proper ventilation and protective equipment.

- Extreme temperatures: Take precautions against heat stress or hypothermia while working in extreme weather conditions.

- Physical exertion: Practice proper lifting techniques and avoid overexertion to prevent injuries.

6. Describe your experience in diagnosing and repairing surface defects.

- Cracks: Identify the cause (e.g., movement, settlement) and repair with appropriate materials.

- Potholes: Remove damaged material, prepare the base, and fill with new material, ensuring proper compaction.

- Uneven surfaces: Level the surface using grinding or patching techniques.

- Drainage issues: Assess the cause of water accumulation and implement drainage improvements.

7. How do you stay up-to-date with the latest surfacing techniques and materials?

- Attend industry conferences and workshops: Engage with experts and learn about new technologies and trends.

- Read trade publications and online resources: Stay informed about the latest materials, equipment, and best practices.

- Network with peers: Build connections and exchange knowledge with other surfacing professionals.

8. Explain the importance of proper jointing and sealing in surfacing work.

- Prevent water infiltration: Joints and seals protect against water damage, which can lead to structural issues.

- Enhance durability: Proper jointing and sealing prevent cracking and deterioration, extending the lifespan of the surface.

- Improve aesthetics: Well-sealed joints and edges enhance the visual appeal of the surfaced area.

9. What is your approach to managing a team of surfacing technicians?

- Clear communication: Establish clear expectations, roles, and responsibilities for team members.

- Effective supervision: Monitor progress, provide guidance, and ensure quality control.

- Collaboration: Foster a positive and collaborative work environment where team members support each other.

- Professional development: Encourage team members to enhance their skills and knowledge through training and mentorship.

10. How do you ensure customer satisfaction with your surfacing work?

- Understanding the client’s needs: Listen attentively to the client’s requirements and preferences.

- Clear communication: Keep the client informed about the project’s progress and any potential challenges.

- High-quality workmanship: Deliver work that meets or exceeds the client’s expectations, ensuring durability and aesthetics.

- Timely completion: Manage the project efficiently to meet agreed deadlines.

- Responsive aftercare: Address any post-installation concerns or issues promptly and professionally.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Surfacing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Surfacing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A skilled Surfacing Technician is a valuable asset for any organization. The primary goal of a Surfacing Technician is to provide high-quality surface finishes on various materials. Their responsibilities include:

1. Surface Preparation

Preparing surfaces involves several meticulous steps, such as:

- Cleaning and degreasing surfaces to ensure proper adhesion.

- Applying primers and coatings to enhance surface durability.

- Sanding and polishing surfaces to achieve desired smoothness and texture.

2. Coating Application

Applying coatings requires careful attention to detail and precision:

- Selecting and mixing appropriate coating materials based on surface requirements.

- Using spray guns, brushes, or other tools to apply coatings evenly and efficiently.

- Controlling coating thickness and drying time to ensure optimal results.

3. Quality Assurance and Control

Maintaining high standards of quality is crucial:

- Inspecting surfaces before, during, and after the surfacing process.

- Identifying and correcting defects or inconsistencies in the surface finish.

- Adhering to established quality standards and ensuring compliance with industry regulations.

4. Troubleshooting and Repair

Addressing issues promptly is essential to maintain productivity:

- Diagnosing problems related to surface preparation or coating application.

- Performing repairs or touch-ups to restore the surface to its intended condition.

- Taking preventive measures to minimize future issues.

Interview Tips

To ace the interview for a Surfacing Technician position, it’s crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Learn about the company’s background, mission, and values. Research the specific role to understand its responsibilities and requirements.

2. Practice Answering Common Interview Questions

Prepare responses to typical interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Examples:

- For “Tell me about yourself,” instead of just stating your name and job title, highlight your relevant skills and experience that align with the job requirements.

- For “Why are you interested in this position?” emphasize your passion for surface finishing and how your expertise can contribute to the company’s success.

3. Showcase Your Technical Skills

Highlight your proficiency in surface preparation techniques, coating application methods, and quality control procedures. Mention any certifications or training you have obtained.

4. Demonstrate Your Problem-Solving Abilities

Share experiences where you successfully diagnosed and resolved issues related to surface finishing. Explain your approach to troubleshooting and your ability to find effective solutions.

5. Emphasize Your Attention to Detail

Stress your commitment to producing high-quality work and your meticulous approach to surface preparation and coating application. Provide examples of your attention to detail.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s projects, the team you’ll be working with, or opportunities for professional development.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive on time for your interview. This shows respect for the interviewer and the company.

Next Step:

Now that you’re armed with the knowledge of Surfacing Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Surfacing Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini