Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Surfboard Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

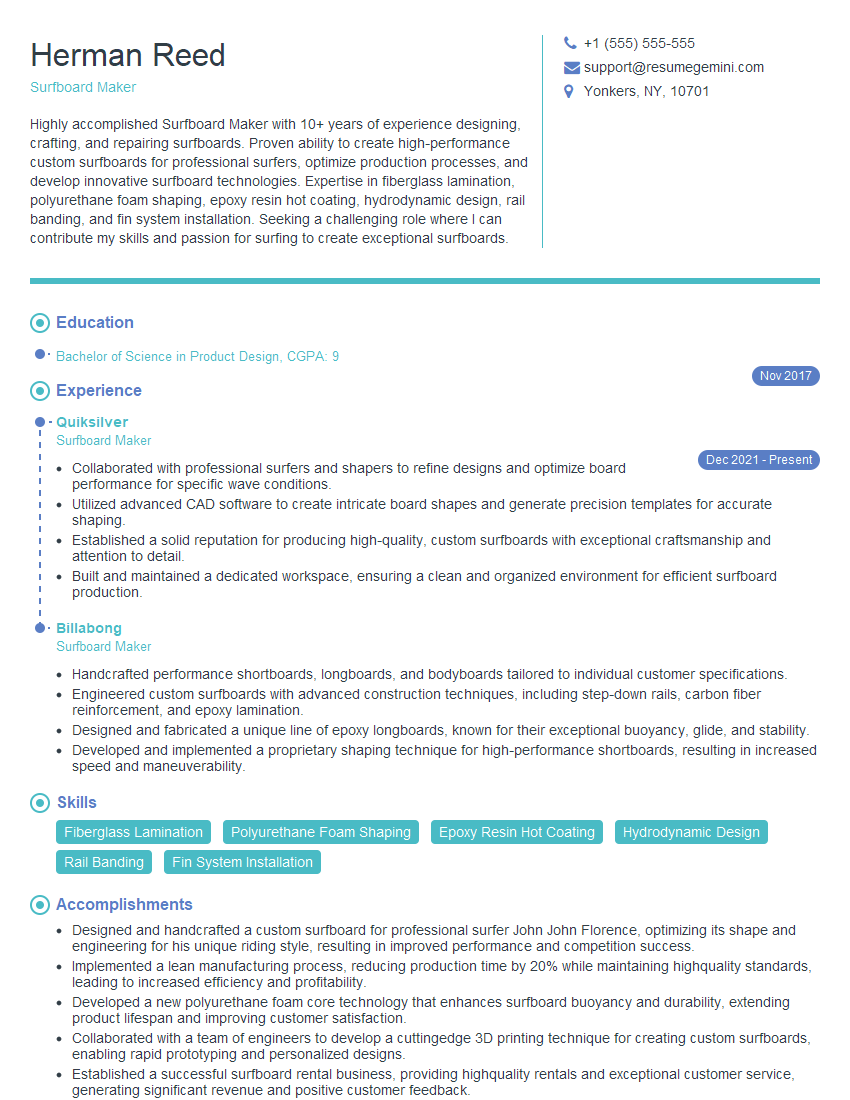

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Surfboard Maker

1. How do you determine the appropriate size and shape of a surfboard for a particular customer?

- Consider the customer’s height, weight, experience level, and surfing style.

- Measure the customer’s torso, arm length, and leg length to determine the ideal board length and width.

- Assess the customer’s ability to control and maneuver the board based on their experience level.

- Determine the type of waves the customer will typically be surfing and match the board design to those conditions (e.g., shortboard for fast waves, longboard for mellow waves).

2. What are the key factors that influence the performance of a surfboard?

Material and construction:

- Foam core (polystyrene, polyurethane, or epoxy) provides buoyancy and shape.

- Fiberglass or carbon fiber layers provide strength and durability.

Shape:

- Length, width, and thickness affect speed, stability, and maneuverability.

- Rocker (curve from nose to tail) influences how the board reacts to water.

- Fins (shape, size, and placement) provide control and help the board turn.

Design:

- Concave or convex bottom shapes can affect speed and maneuverability.

- Tail shape (e.g., swallowtail, squaretail) influences how the board responds to different waves.

- Artwork and graphics can affect the board’s aesthetic appeal.

3. Explain the process of shaping a custom surfboard from start to finish.

- Select the appropriate foam blank based on the desired size and shape.

- Use shaping tools (e.g., planer, hot wire, rasp) to carve and refine the blank.

- Apply fiberglass layers and resin to strengthen the board.

- Sand and finish the board to achieve the desired look and feel.

- Install fins and other accessories as necessary.

4. How do you repair common surfboard damage, such as dings and cracks?

- For small dings: Sand the affected area, apply epoxy or resin, and sand again to smooth.

- For cracks: Clean and dry the area. Fill the crack with epoxy or resin. Clamp the board together and allow it to dry.

- For larger repairs: May involve removing damaged foam and replacing it with new foam, then reinforcing with fiberglass and resin.

5. What are the different types of surfboard fins and how do they affect board performance?

Single fin:

- Provides stability and drive.

- Suited for longboards and traditional surfboards.

Twin fins:

- Offer more maneuverability than a single fin.

- Popular for fish and shortboards.

Three fins (thruster):

- Provides a balance of stability and maneuverability.

- Versatile design suitable for various wave types and skill levels.

Quad fins:

- Similar to thrusters but with an additional two fins near the tail.

- Offers increased drive and control in small waves.

6. How do you ensure the safety and quality of the surfboards you produce?

- Use high-quality materials and follow industry standards for construction.

- Inspect each board thoroughly before and after shaping and finishing.

- Test surfboards in various wave conditions to assess performance and durability.

- Provide customers with clear instructions and recommendations for proper use and care of their surfboards.

7. What is your approach to understanding and meeting customer needs when designing and building custom surfboards?

- Consult with customers to gather their specific requirements and preferences.

- Analyze their surfing style, experience level, and intended use for the board.

- Provide guidance and recommendations based on their needs and technical knowledge.

- Collaborate with customers throughout the design and shaping process to ensure their satisfaction.

8. Describe a time when you had to troubleshoot and resolve a technical issue related to surfboard design or construction.

- Explain the issue encountered, including symptoms and potential causes.

- Describe the steps taken to diagnose and identify the root cause.

- Explain the solution implemented to resolve the issue effectively.

- Discuss the lessons learned and how it improved future design or construction practices.

9. How do you stay up-to-date with the latest trends and advancements in surfboard technology?

- Attend industry trade shows and conferences.

- Read surf magazines and online forums.

- Collaborate with other surfboard makers and experiment with new materials and designs.

- Conduct research on hydrodynamic principles and board performance.

10. What sets your surfboard-making skills apart from other candidates and makes you the ideal choice for this role?

- Highlight your extensive experience and expertise in shaping and designing custom surfboards.

- Emphasize your understanding of surfboard physics and hydrodynamics.

- Mention your ability to troubleshoot and resolve technical issues effectively.

- Showcase your strong communication and customer service skills.

- Express your passion for surfing and your commitment to delivering exceptional surfboards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Surfboard Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Surfboard Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Surfboard makers, also known as shapers, are responsible for designing, building, and repairing surfboards. They work closely with customers to understand their specific requirements and preferences, and then use their skills and knowledge to create custom surfboards that meet those needs.

1. Design and shape surfboards

Surfboard makers typically start by designing the shape of the surfboard, which is determined by a number of factors, including the surfer’s size, weight, and surfing style. Once the shape has been designed, the maker will use a variety of tools to cut and shape the foam blank into the desired shape.

- Read and interpret blueprints and specifications

- Use hand and power tools to shape and finish surfboards

2. Laminate and finish surfboards

Once the surfboard has been shaped, it is laminated with fiberglass or other materials to make it strong and durable. The maker will then apply a finish to the surfboard, which can include sanding, polishing, and painting.

- Apply fiberglass or other materials to the surfboard

- Sand, polish, and paint the surfboard

3. Repair surfboards

Surfboards can be damaged during use, so surfboard makers are also responsible for repairing them. Repairs can range from simple fixes, such as repairing a ding in the foam, to more complex repairs, such as fixing a broken fin box.

- Identify and assess damage to surfboards

- Repair or replace damaged parts

4. Other duties

In addition to the above duties, surfboard makers may also be responsible for:

- Ordering and maintaining supplies

- Providing customer service

- Marketing and selling surfboards

Interview Tips

Preparing for a surfboard maker interview can be a daunting task, but by following these tips you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a surfboard maker.

- Visit the company’s website

- Read articles about the company and its products

- Talk to people who work at the company

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Use the STAR method to answer questions

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the job of a surfboard maker. This includes your experience in shaping, laminating, and repairing surfboards, as well as your knowledge of different materials and techniques.

- Quantify your accomplishments

- Use specific examples to illustrate your skills

4. Be enthusiastic and passionate

Surfboard makers are typically passionate about their work, so it is important to show your enthusiasm and passion in your interview. This will help you stand out from other candidates and show the interviewer that you are genuinely interested in the position.

- Share your knowledge and experience

- Ask questions about the company and the position

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Surfboard Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.