Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Surgical Forceps Fabricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

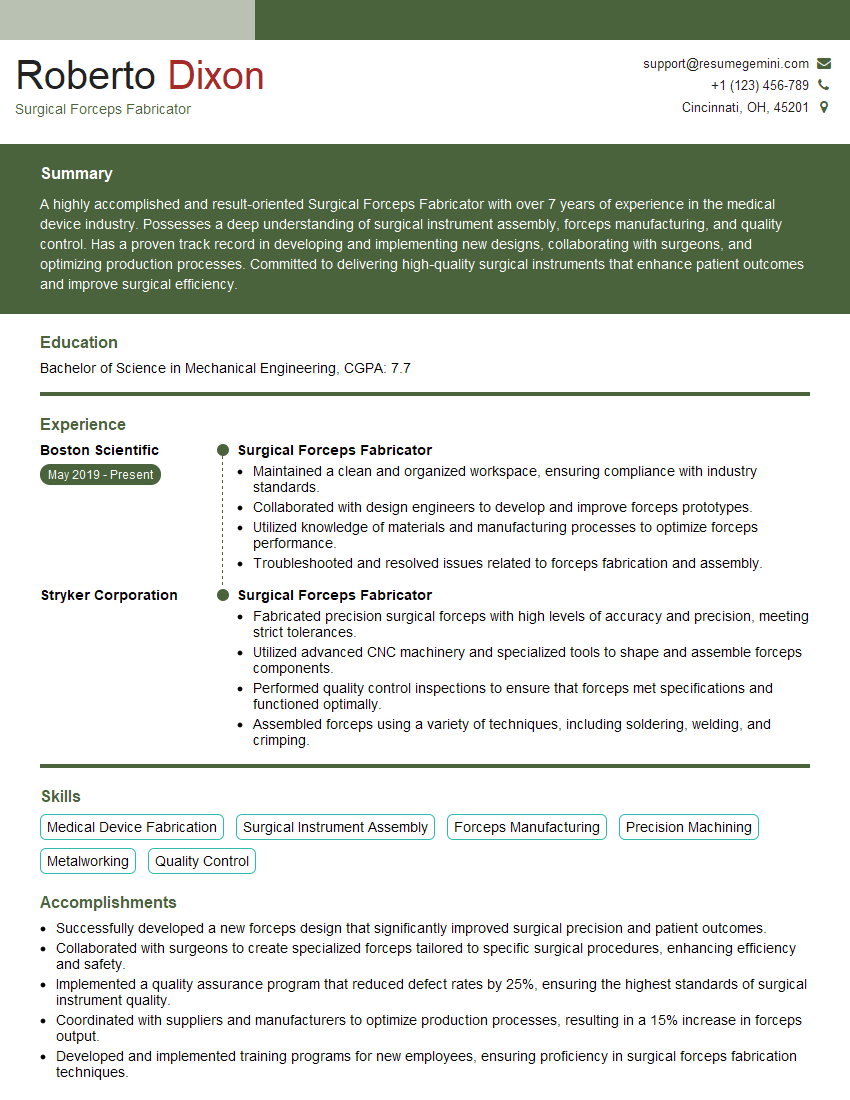

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Surgical Forceps Fabricator

1. Describe the process of fabricating surgical forceps, including the materials and tools used?

The process of fabricating surgical forceps involves the following steps:

- Selection of materials: The first step is to select the right materials for the forceps. The most common materials used for surgical forceps are stainless steel, titanium, and tungsten carbide. The choice of material depends on the specific application of the forceps.

- Cutting and shaping: Once the materials have been selected, they are cut and shaped into the desired form. This can be done using a variety of tools, including saws, shears, and grinders.

- Heat treating: The forceps are then heat treated to improve their strength and durability. This is done by heating the forceps to a high temperature and then cooling them slowly.

- Polishing: The forceps are then polished to remove any burrs or sharp edges. This is done using a variety of abrasives, including sandpaper and polishing wheels.

- Assembly: The final step is to assemble the forceps. This involves attaching the handles to the tips of the forceps. The forceps are then tested to ensure that they meet the required specifications.

2. How do you ensure the accuracy and precision of the finished product?

Quality control

- Dimensional accuracy: The dimensions of the forceps are critical to their performance. To ensure accuracy, the forceps are inspected using a variety of measuring tools, including calipers and micrometers.

- Surface finish: The surface finish of the forceps is also important to their performance. A smooth surface finish helps to prevent the forceps from sticking to tissue or causing damage. To achieve a smooth surface finish, the forceps are polished using a variety of abrasives, including sandpaper and polishing wheels.

Testing

- Functional testing: The forceps are tested to ensure that they meet the required functional specifications. This includes testing the forceps for strength, durability, and cutting ability.

- Sterilization testing: The forceps are also tested to ensure that they can be sterilized without damage. This is done by exposing the forceps to a variety of sterilization methods, including steam sterilization and chemical sterilization.

3. What are the different types of surgical forceps and what are their uses?

- Hemostatic forceps: Hemostatic forceps are used to clamp blood vessels and stop bleeding. They have a serrated surface that helps to grip the blood vessel and prevent it from slipping.

- Tissue forceps: Tissue forceps are used to hold and manipulate tissue. They have a smooth surface that helps to prevent damage to the tissue.

- Dissecting forceps: Dissecting forceps are used to cut and dissect tissue. They have a sharp edge that helps to make precise cuts.

- Needle holders: Needle holders are used to hold and manipulate needles. They have a locking mechanism that helps to keep the needle secure.

4. What are the safety precautions that must be taken when working with surgical forceps?

- Always wear gloves when handling surgical forceps. This will help to protect your hands from cuts and abrasions.

- Never use surgical forceps on a patient who is awake. This could cause serious injury.

- Always inspect surgical forceps before using them. Make sure that the forceps are in good condition and that there are no loose parts.

- Never use surgical forceps for any purpose other than their intended purpose. This could damage the forceps or cause injury to the patient.

- Always dispose of surgical forceps properly. This will help to prevent the spread of infection.

5. What are the latest trends in surgical forceps design?

- Miniaturization: Surgical forceps are becoming increasingly smaller and more precise. This is due to the need for minimally invasive surgery, which requires smaller incisions and less tissue damage.

- Multifunctionality: Surgical forceps are becoming more multifunctional. This means that they can be used for a variety of purposes, such as grasping, cutting, and dissecting.

- Improved materials: New materials are being used to make surgical forceps, such as titanium and tungsten carbide. These materials are stronger and more durable than traditional materials, which makes them ideal for use in demanding surgical applications.

6. What are the challenges in fabricating surgical forceps?

- Precision: Surgical forceps must be extremely precise in order to perform their intended function. This can be difficult to achieve, especially when working with small or delicate instruments.

- Materials: The materials used to fabricate surgical forceps must be strong, durable, and biocompatible. This can be a challenge, as many materials that meet these requirements are also difficult to work with.

- Sterilization: Surgical forceps must be able to withstand repeated sterilization cycles without damage. This can be a challenge, as some sterilization methods can be harsh on materials.

7. How do you stay up-to-date on the latest advancements in surgical forceps design and fabrication?

- Attend industry conferences and trade shows. This is a great way to learn about new products and technologies from leading manufacturers.

- Read industry publications. There are a number of journals and magazines that cover the latest advancements in surgical forceps design and fabrication.

- Network with other professionals in the field. This can be a great way to learn about new techniques and technologies that are being used by other surgeons.

8. What are your strengths and weaknesses as a surgical forceps fabricator?

- Strengths:

- I have a strong understanding of the principles of surgical forceps design and fabrication.

- I am skilled in using a variety of tools and equipment to fabricate surgical forceps.

- I am committed to producing high-quality surgical forceps that meet the needs of surgeons.

- Weaknesses:

- I am relatively new to the field of surgical forceps fabrication.

- I am not yet familiar with all of the latest advancements in surgical forceps design and fabrication.

- I do not have any experience with fabricating surgical forceps for minimally invasive surgery.

9. Why are you interested in working as a surgical forceps fabricator?

I am interested in working as a surgical forceps fabricator because I am passionate about helping surgeons to perform their jobs more effectively. I believe that surgical forceps are essential tools for surgeons, and I am committed to producing high-quality forceps that meet the needs of surgeons. I am also interested in the challenges of surgical forceps fabrication, and I am confident that I have the skills and experience necessary to be successful in this field.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can make a valuable contribution to your company, and I am looking for a salary that reflects my worth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Surgical Forceps Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Surgical Forceps Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Surgical Forceps Fabricator is responsible for designing, fabricating, and modifying surgical forceps and related instruments used in the medical field. Below are key job responsibilities of Surgical Forceps Fabricator.

1. Design and Development

Creating technical drawings and specifications for new or modified surgical forceps designs.

- Collaborating with design engineers, physicians, and surgeons to develop innovative forceps solutions.

- Analyzing existing forceps designs and identifying areas for improvement.

2. Fabrication and Assembly

Using specialized tools and techniques to fabricate forceps components from various materials, including stainless steel, titanium, and plastics.

- Assembling and welding forceps components to create functional prototypes.

- Conducting quality control checks to ensure that forceps meet specifications.

3. Testing and Evaluation

Testing fabricated forceps to assess their performance, functionality, and durability.

- Recording and analyzing test results to identify areas for design refinement.

- Working with surgeons to provide feedback on forceps performance and incorporate their suggestions into future designs.

4. Maintenance and Repair

Performing maintenance and repair on existing surgical forceps.

- Diagnosing and resolving issues with forceps, such as malfunctions, broken components, or dull blades.

- Sharpening and adjusting forceps to ensure optimal performance.

Interview Tips

To help candidates ace the interview for a Surgical Forceps Fabricator position, here are some interview preparation tips and hacks:

1. Research the Company and Role

Familiarize yourself with the company’s mission, values, and products. Research the specific role and its responsibilities to understand the company’s expectations.

- Visit the company’s website and LinkedIn page to gather information.

- Reach out to current or former employees for insights into the company culture and work environment.

2. Highlight Relevant Skills and Experience

In your resume and interview answers, emphasize your skills and experience that are relevant to the job requirements.

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Use keywords from the job description to tailor your resume and interview responses.

3. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your thoughts clearly and confidently during the interview.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Record yourself practicing to identify areas for improvement.

4. Ask Informed Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement.

- Inquire about the company’s plans for future product development.

- Ask about opportunities for professional development and growth within the organization.

5. Follow Up

Within 24 hours of the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and highlight any additional qualifications or experiences that you feel would add value to the company.

- Use the opportunity to address any questions or concerns that the interviewer may have.

- Let the interviewer know that you are available for further discussions or questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Surgical Forceps Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!