Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Swedger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

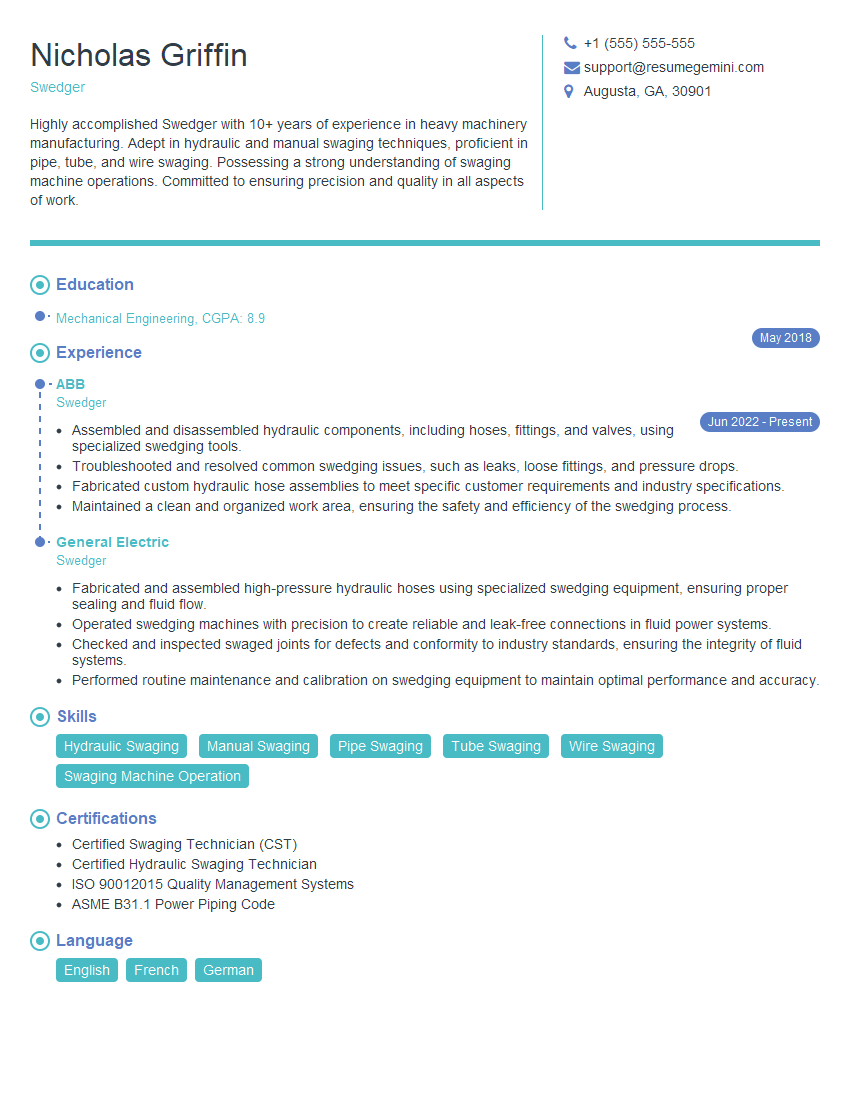

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swedger

1. What is Swedging? Explain the process briefly.

Swedging is a metalworking process that involves reducing the diameter of a tube or pipe by hammering or pressing it into a die. The process is typically used to create a tight fit between two pieces of metal, or to create a specific shape or profile in the metal.

2. Describe the different types of Swedging machines. What are the advantages and disadvantages of each?

Mechanical swedging machines

- Advantages: High production rates, low cost, simple to operate.

- Disadvantages: Limited capacity, can only produce simple shapes.

Hydraulic swedging machines

- Advantages: High capacity, can produce complex shapes, precise control.

- Disadvantages: Slower production rates, higher cost, more complex to operate.

3. What are the key factors that affect the quality of a swedged joint?

- The condition of the dies

- The material properties of the tube or pipe

- The lubrication used during the process

- The skill of the operator

4. What are the common applications of swedging?

- Creating tight fits between two pieces of metal

- Creating specific shapes or profiles in metal

- Repairing damaged tubes or pipes

- Assembling metal components

5. What are the safety precautions that should be taken when operating a swedging machine?

- Wear appropriate PPE, including safety glasses,

- gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine if it is damaged or malfunctioning.

- Always follow the manufacturer’s instructions for operating the machine.

6. What are the benefits of using swedging over other metalworking processes?

- Swedging is a relatively low-cost process.

- Swedging can be used to create a wide variety of shapes and sizes.

- Swedging is a precise process that can produce high-quality joints.

- Swedging is a relatively fast process.

7. What are the challenges of using swedging?

- Swedging can be a dangerous process if proper safety precautions are not taken.

- Swedging can be a time-consuming process, especially for complex shapes.

- Swedging can require specialized equipment and tooling.

- Swedging can be difficult to perform on certain types of materials.

8. What is the difference between swedging and flaring?

- Swedging is a process of reducing the diameter of a tube or pipe by hammering or pressing it into a die.

- Flaring is a process of expanding the end of a tube or pipe by hammering or pressing it into a die.

9. What is the difference between swedging and beading?

- Swedging is a process of reducing the diameter of a tube or pipe by hammering or pressing it into a die.

- Beading is a process of creating a raised edge on a tube or pipe by hammering or pressing it into a die.

10. What are the latest trends in swedging technology?

- The use of CNC machines to automate the swedging process.

- The development of new swedging dies that can produce more complex shapes.

- The use of new materials that are better suited for swedging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swedger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swedger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Swedger, your primary focus will be on the production and repair of cables and wires. Your responsibilities demand precision, technical expertise, and unwavering adherence to industry standards.

1. Cable and Wire Production

You will play a vital role in the manufacturing process of various cables and wires, ensuring they meet exact specifications. This includes:

- Fabricating cables of varying lengths, gauges, and insulation types.

- Operating specialized machinery, such as swaging machines, to join and terminate cables.

2. Cable and Wire Repair

When cables or wires are damaged, your expertise will be utilized to restore their functionality promptly and effectively.

- Diagnosing cable and wire faults using testing equipment and troubleshooting techniques.

- Repairing damaged sections by splicing, soldering, or replacing faulty components.

3. Quality Control and Inspection

Maintaining the highest standards of quality is paramount, and you will be responsible for:

- Performing thorough inspections of produced and repaired cables and wires.

- Testing and verifying their electrical and mechanical properties to ensure compliance with specifications.

4. Inventory Management and Maintenance

You will oversee the inventory of raw materials and ensure adequate supplies. Additionally:

- Maintaining and calibrating swaging machines and other equipment to optimize performance.

- Adhering to safety protocols and environmental regulations.

Interview Tips

Preparing effectively for your Swedger interview can significantly increase your chances of success. Here are some crucial tips:

1. Research the Company and Role

Take the time to learn about the company, its industry, and the specific role you are applying for. This will enable you to speak intelligently about your qualifications and how they align with the company’s needs.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to emphasize your relevant experience and skills. Quantify your accomplishments whenever possible to showcase the impact of your contributions.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your technical abilities, problem-solving skills, and attention to detail. Practice answering them concisely and professionally.

4. Ask Insightful Questions

During the interview, ask thoughtful questions about the company, the role, and the industry. This demonstrates your engagement and interest in the position.

5. Showcase Your Knowledge of Swaging Techniques

Highlight your expertise in swaging techniques, including your understanding of different swaging machines and the ability to produce high-quality cable terminations.

6. Express Your Passion for Accuracy and Precision

Emphasize your commitment to accuracy and precision in all aspects of your work. Explain how you maintain a high level of quality in your cable and wire production and repair processes.

7. Prepare for a Hands-On Assessment

Some interviews may include a hands-on assessment of your swaging skills. Practice working with swaging machines and demonstrate your proficiency in producing quality cable terminations.

8. Be Confident and Professional

Approach the interview with confidence and professionalism. Dress appropriately, arrive on time, and maintain a positive attitude throughout the process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Swedger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.