Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sweep Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sweep Molder so you can tailor your answers to impress potential employers.

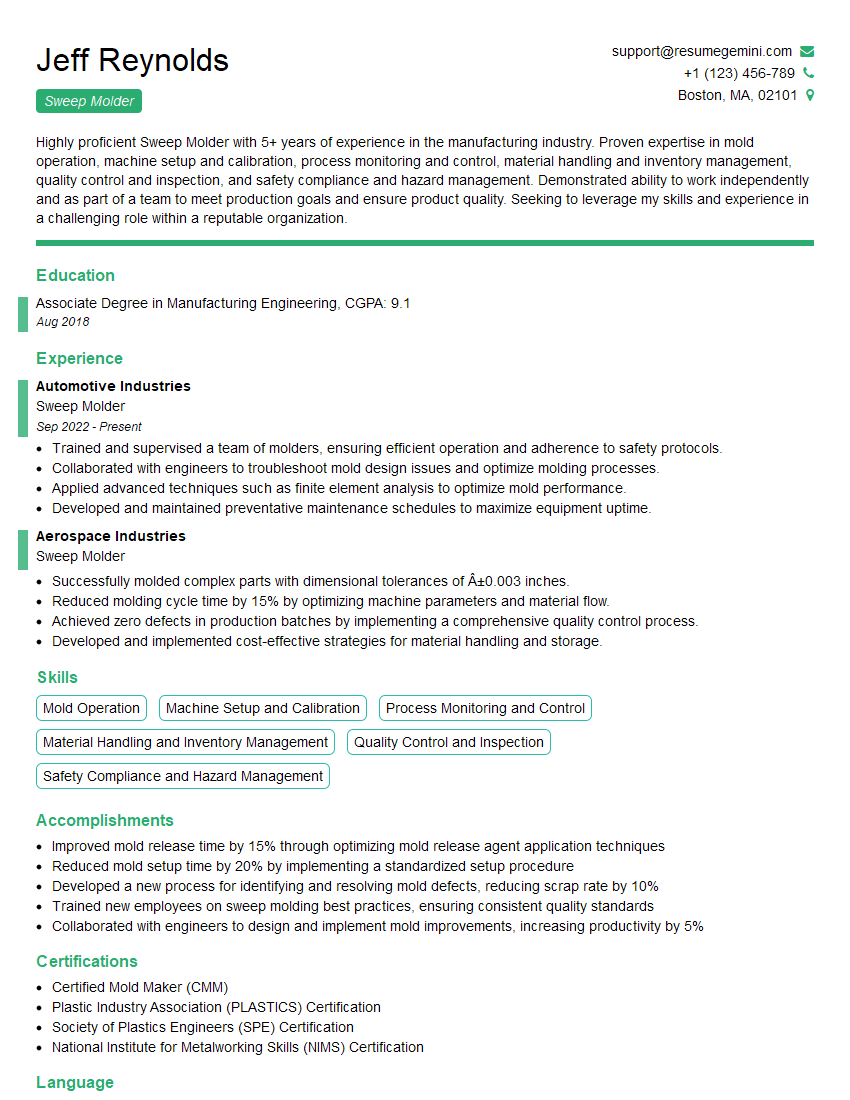

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sweep Molder

1. Describe the sweep molding process in detail.

- Sweep molding is a casting process in which a mold is created by sweeping a pattern over a surface.

- The pattern is typically made of wood or metal and is shaped to the desired contour of the casting.

- The pattern is attached to a sweep arm, which is then rotated over the surface of a sand bed.

- As the sweep arm rotates, the pattern creates a mold cavity in the sand.

- Molten metal is then poured into the mold cavity and allowed to solidify.

- Once the metal has solidified, the mold is broken away and the casting is removed.

2. What are the different types of sweep molding?

- There are two main types of sweep molding: vertical sweep molding and horizontal sweep molding.

- In vertical sweep molding, the sweep arm is rotated vertically over the surface of the sand bed.

- In horizontal sweep molding, the sweep arm is rotated horizontally over the surface of the sand bed.

3. What are the advantages of sweep molding?

- Sweep molding is a relatively simple and inexpensive process.

- It can be used to produce castings with complex shapes.

- Sweep molding is also a versatile process that can be used to produce castings in a variety of materials.

4. What are the disadvantages of sweep molding?

- Sweep molding can be a time-consuming process, especially for castings with complex shapes.

- Sweep molding can also be a labor-intensive process, as it requires a skilled operator to create the mold.

5. What are the different applications of sweep molding?

- Sweep molding is used to produce a variety of castings, including engine blocks, cylinder heads, and other complex shapes.

- Sweep molding is also used to produce castings for the aerospace, automotive, and other industries.

6. What are the safety precautions that must be taken when operating a sweep molding machine?

- Sweep molding machines can be dangerous if they are not operated properly.

- It is important to wear proper safety gear, including gloves, safety glasses, and a hard hat.

- It is also important to keep the work area clean and free of debris.

7. What are the maintenance procedures that must be performed on a sweep molding machine?

- Sweep molding machines require regular maintenance to keep them operating properly.

- It is important to inspect the machine regularly for any signs of wear or damage.

- It is also important to lubricate the machine regularly according to the manufacturer’s instructions.

8. How do you troubleshoot a sweep molding machine?

- If a sweep molding machine is not operating properly, it is important to troubleshoot the problem.

- The first step is to identify the source of the problem.

- Once the source of the problem has been identified, it can be repaired.

9. What are the different types of defects that can occur in sweep molding?

- There are a variety of defects that can occur in sweep molding, including:

- shrinkage porosity

- cold shuts

- hot tears

- misruns

- fins

- flash

10. How do you prevent defects from occurring in sweep molding?

- There are a variety of ways to prevent defects from occurring in sweep molding, including:

- using the correct materials

- using the correct process parameters

- maintaining the equipment properly

- training operators properly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sweep Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sweep Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sweep Molders usually work in a foundry environment and are responsible for using a “sweep” to form molds for molten metal castings. The sweep is a long, narrow tool, usually made of wood or metal, that is used to create the shape of the mold. Sweep Molders use various techniques, such as sweeping, ramming, and venting, to create the molds.

1. Preparing the Molding Flask

Sweep Molders start by preparing the molding flask, which is a box-like container that holds the sand used to create the mold. They make sure the flask is clean and free of any debris and then place it on a molding board.

2. Creating the Mold Cavity

Using a sweep, Sweep Molders create the shape of the mold cavity by sweeping the sand in a specific pattern. The sweep is typically attached to a spindle, which allows Sweep Molders to rotate the sweep and create a more complex shape.

3. Ramming the Sand

Once the mold cavity is created, Sweep Molders use a rammer to pack the sand tightly around the sweep. This helps to ensure that the mold is strong enough to withstand the molten metal when it is poured.

4. Venting the Mold

Sweep Molders also vent the mold by creating small holes in the sand. These holes allow gases to escape from the mold during the casting process, which helps to prevent defects in the final casting.

5. Finishing the Mold

Once the mold is complete, Sweep Molders finish it by smoothing out the surface of the sand and removing any excess sand. They may also apply a parting agent to the mold to help prevent the casting from sticking to the sand.

Interview Tips

Preparing for an interview for a Sweep Molder position requires a combination of technical knowledge, research, and practice. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Before the interview, take some time to research the company you are applying to and the specific Sweep Molder position. This will give you a better understanding of the company’s culture, values, and the specific requirements of the role.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently during the interview.

3. Highlight Your Relevant Skills and Experience

In your resume and during the interview, make sure to highlight your relevant skills and experience. Employers will be looking for candidates with a strong understanding of the sweep molding process, as well as experience in using a variety of tools and equipment. Be sure to emphasize any specific skills or certifications that you have that are relevant to the position.

4. Be Prepared to Discuss Safety Procedures

Safety is a critical aspect of the Sweep Molder role, so be prepared to discuss your understanding of safety procedures and your commitment to working safely. Employers will be looking for candidates who are aware of the potential hazards associated with the job and who have a strong track record of following safety protocols.

5. Ask Questions

At the end of the interview, take the opportunity to ask the interviewer any questions you have about the position or the company. This shows that you are engaged and interested in the opportunity, and it gives you a chance to clarify any details that you may have missed during the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Sweep Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.