Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Swiss Type Screw Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

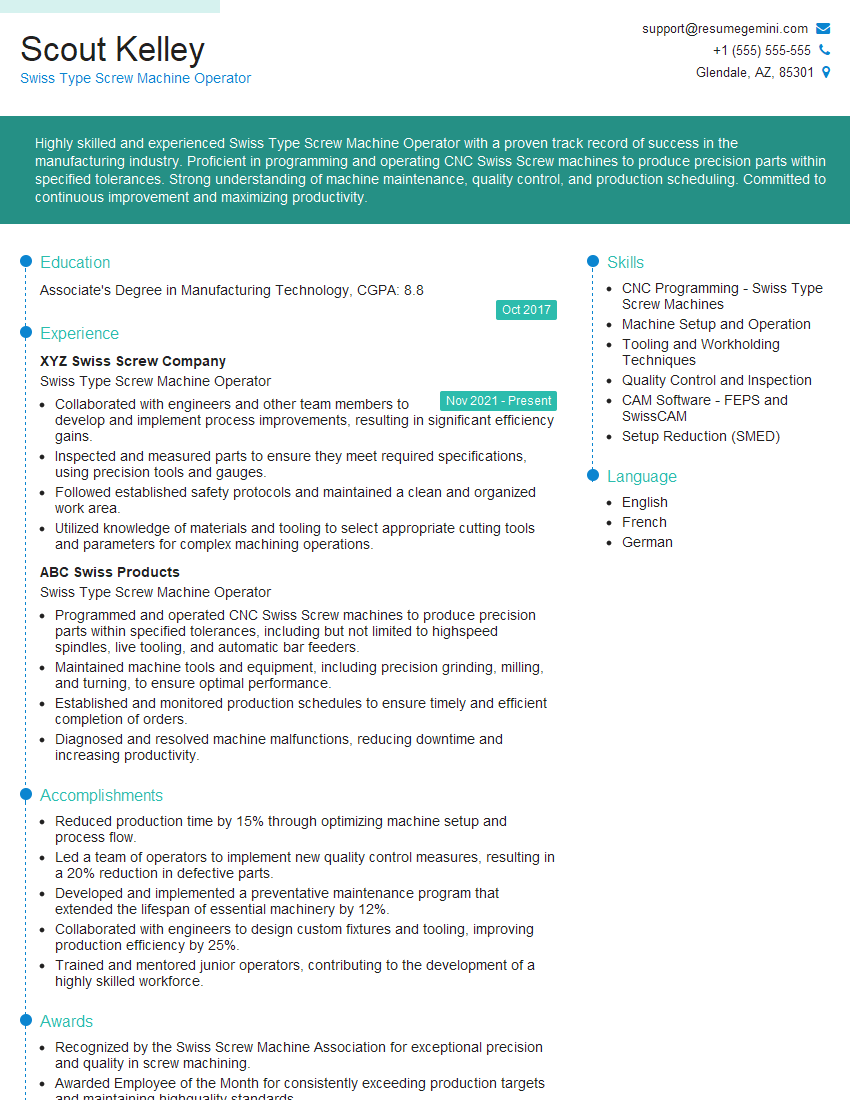

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swiss Type Screw Machine Operator

1. Describe the key steps involved in setting up and operating a Swiss-type screw machine?

- Prepare the machine by installing the appropriate tooling, fixtures, and materials.

- Program the machine to run the desired part program.

- Load the raw material into the machine.

- Start the machine and monitor its operation to ensure that it is running smoothly.

- Unload the finished parts from the machine.

2. Explain the principles of Swiss-type screw machining and how it differs from traditional screw machining?

Principles of Swiss-type screw machining

- Uses a rotating tool to cut material from a stationary workpiece.

- Produces parts with high precision and accuracy.

- Can be used to produce complex parts with multiple features.

Differences from traditional screw machining

- Swiss-type screw machines use a guide bushing to support the tool during cutting, which results in improved accuracy and reduced vibration.

- Swiss-type screw machines are typically equipped with multiple spindles, which allows for simultaneous operations such as turning, drilling, and threading.

- Swiss-type screw machines use coolant under high pressure to remove chips and lubricate the cutting tool, which results in improved tool life and surface finish.

3. How do you approach troubleshooting when a Swiss-type screw machine is not operating properly?

- Identify the problem by observing the machine’s operation and error messages.

- Check for mechanical issues such as loose belts, worn bearings, or misaligned components.

- Check for electrical issues such as faulty sensors, wiring problems, or power outages.

- Check for programming errors in the machine’s CNC controller.

- Consult the machine’s manual or consult with a qualified technician for assistance.

4. How do you ensure the quality of parts produced on a Swiss-type screw machine?

- Use high-quality materials and tooling.

- Properly set up and operate the machine.

- Regularly calibrate and maintain the machine.

- Inspect parts regularly during and after production.

- Use statistical process control (SPC) to monitor and improve the quality of parts.

5. What are the safety precautions that should be taken when operating a Swiss-type screw machine?

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Be aware of the moving parts of the machine and keep hands and clothing away from them.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Follow all lockout/tagout procedures when servicing the machine.

6. How do you maintain a Swiss-type screw machine?

- Regularly clean and lubricate the machine.

- Inspect the machine for wear and tear, and replace worn parts as needed.

- Calibrate the machine regularly to ensure accuracy.

- Follow the manufacturer’s recommended maintenance schedule.

- Keep a maintenance log to track all maintenance activities.

7. What is your experience with programming Swiss-type screw machines?

Provide details of your experience, including the types of machines you have programmed, the programming languages you are familiar with, and the types of parts you have produced.

8. What are your strengths as a Swiss-type screw machine operator?

- Strong attention to detail.

- Ability to work independently and as part of a team.

- Proficient in programming and operating Swiss-type screw machines.

- Excellent troubleshooting skills.

- Commitment to quality and safety.

9. What are your career goals?

Explain how this position aligns with your career goals and how you plan to contribute to the company.

10. What questions do you have for me?

Ask thoughtful questions that demonstrate your interest in the position and the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swiss Type Screw Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swiss Type Screw Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Swiss Type Screw Machine Operators play a crucial role in the production of precision components utilizing advanced CNC Swiss-type screw machines.

1. Machine Operation

Operate Swiss-type screw machines to manufacture complex parts according to specifications and blueprints.

- Set up and adjust machines, ensuring optimal performance.

- Load and feed raw materials, monitor production, and ensure quality.

2. Tooling and Maintenance

Maintain and troubleshoot Swiss-type screw machines and peripheral equipment.

- Inspect and replace tooling as needed.

- Lubricate and adjust machines to prevent breakdowns and maintain efficiency.

3. Quality Control

Inspect finished parts to ensure they meet specifications and quality standards.

- Use precision measuring instruments to verify dimensions and tolerances.

- Identify and correct any discrepancies or defects.

4. Production Planning and Scheduling

Assist in production planning and scheduling to optimize machine utilization and meet deadlines.

- Collaborate with supervisors and other team members to ensure smooth production flow.

- Monitor production progress and identify potential bottlenecks.

Interview Tips

To ace an interview for a Swiss Type Screw Machine Operator position, it’s essential to:

1. Highlight Relevant Experience

Emphasize your experience operating Swiss-type screw machines and working with precision tooling. Quantify your accomplishments and provide specific examples of your contributions.

- Example: “In my previous role, I operated a Star CNC Swiss-type screw machine and consistently produced precision components within tolerances of ±0.0005 inches.”

2. Showcase Machine Knowledge

Demonstrate your in-depth knowledge of Swiss-type screw machines. Discuss the different types of machines, their capabilities, and the various tooling options available.

- Example: “I have experience operating both Citizen and Tornos Swiss-type screw machines and am proficient in setting up and adjusting these machines for complex part production.”

3. Emphasize Quality Assurance

Highlight your commitment to quality assurance. Explain your experience with precision measurement tools and your ability to identify and correct defects.

- Example: “I am proficient in using CMMs and optical comparators to verify the dimensions and tolerances of finished parts. I have consistently met or exceeded quality standards in all my previous roles.”

4. Prepare for Technical Questions

Be prepared for technical questions related to Swiss-type screw machine operation. These may include questions about machine setup, tooling selection, and troubleshooting.

- Example: “Describe the steps involved in setting up a Swiss-type screw machine for a new part production run.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Swiss Type Screw Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!