Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Synthetic Filament Extruder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Synthetic Filament Extruder so you can tailor your answers to impress potential employers.

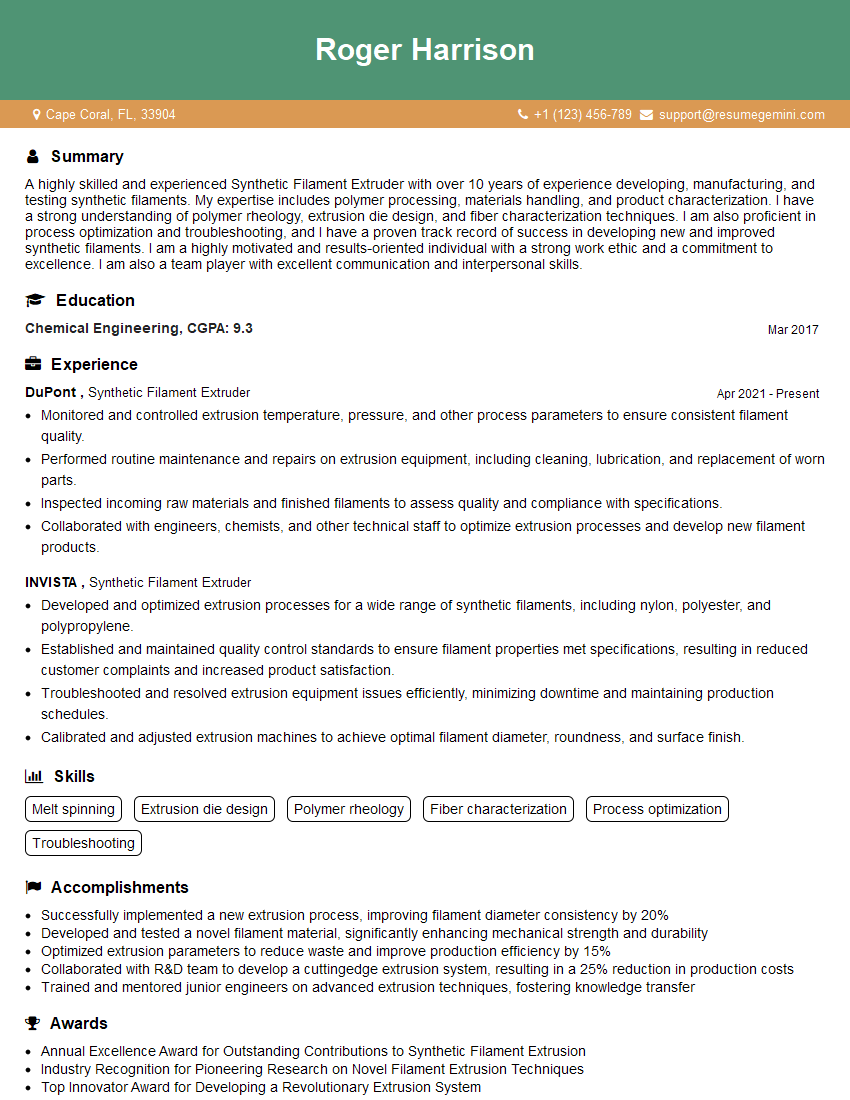

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Synthetic Filament Extruder

1. How would you characterize the quality of a synthetic filament?

- Evenness

- Tenacity

- Elongation at break

- Shrinkage

- Surface smoothness

2. What are the key factors that affect the extrusion process of synthetic filaments?

Process Parameters

- Extruder temperature

- Die temperature

- Screw speed

- Feed rate

- Take-up speed

Material Properties

- Melt viscosity

- Crystallinity

- Molecular weight

- Additives

3. How do you troubleshoot common problems encountered during synthetic filament extrusion?

- Uneven filament diameter

- Filament breakage

- Surface defects

- Inconsistent mechanical properties

- Poor adhesion to substrate

4. What are the different types of dies used in synthetic filament extrusion and their applications?

- Flat dies: producing thin films

- Spinnerets: producing fibers and filaments

- Nozzle dies: producing tubes and hoses

- Co-extrusion dies: producing multilayer filaments

5. How do you optimize the extrusion process for specific filament properties?

- High strength: high extruder temperature, slow screw speed

- High elongation: low extruder temperature, high screw speed

- Low shrinkage: high take-up speed

- Good surface smoothness: clean extruder and die

6. What are the quality control measures for synthetic filaments?

- Diameter measurement

- Tenacity testing

- Elongation testing

- Surface inspection

- Shrinkage testing

7. What are the current trends and advancements in synthetic filament extrusion technology?

- Biodegradable filaments

- Nanoparticle-filled filaments

- Multi-material filaments

- High-speed extrusion

8. What are the safety precautions that should be followed during synthetic filament extrusion?

- Wear appropriate protective gear

- Keep work area clean and free of tripping hazards

- Handle molten filaments with care

- Ventilate the work area properly

9. What are the different applications of synthetic filaments?

- Textiles

- Medical devices

- Automotive parts

- Packaging

- Composite materials

10. What are the emerging applications of synthetic filaments in the field of renewable energy?

- Solar cell substrates

- Wind turbine blades

- Battery separators

- Electrodes for fuel cells

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Synthetic Filament Extruder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Synthetic Filament Extruder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Synthetic Filament Extruder plays a crucial role in the manufacturing process of synthetic filaments. Their key responsibilities include:

1. Extrusion Process Management

Operate and monitor extrusion equipment, ensuring optimal production output and quality.

- Calibrate and adjust extrusion parameters (e.g., temperature, pressure, flow rate).

- Monitor and troubleshoot extrusion issues, identifying and addressing root causes.

2. Product Quality Control

Conduct regular quality checks on extruded filaments, ensuring they meet specifications.

- Perform physical and chemical tests (e.g., tensile strength, diameter measurement).

- Identify and resolve quality deviations, implementing corrective actions.

3. Equipment Maintenance and Troubleshooting

Maintain and troubleshoot extrusion equipment, ensuring smooth operations and preventing downtime.

- Perform preventive maintenance (e.g., cleaning, lubrication).

- Diagnose and repair equipment malfunctions, minimizing production disruptions.

4. Process Optimization and Improvement

Continuously evaluate and improve the extrusion process, seeking ways to enhance efficiency and productivity.

- Identify areas for improvement, implementing process modifications.

- Collaborate with engineers and technicians to develop and implement process innovations.

Interview Tips

To ace the interview for a Synthetic Filament Extruder position, candidates should prepare thoroughly by following these tips:

1. Research and Know the Company

Demonstrate your interest in the company by researching their history, products, and industry standing.

- Visit the company website and social media pages.

- Read industry news and articles to gain insights into the company’s market position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in extrusion processes, quality control, and equipment troubleshooting.

- Quantify your achievements and provide specific examples of your contributions.

- Showcase your problem-solving abilities and attention to detail.

3. Show Interest and Enthusiasm

Convey your passion for the extrusion industry and your eagerness to contribute to the company’s success.

- Ask thoughtful questions about the role and the company’s operations during the interview.

- Express your interest in learning and growing within the organization.

4. Prepare Questions for the Interviewers

Preparing questions demonstrates your engagement and interest in the role and the company.

- Ask about the company’s growth plans and industry outlook.

- Inquire about the specific challenges and opportunities within the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Synthetic Filament Extruder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!