Are you gearing up for a career in Synthetic Gem Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Synthetic Gem Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

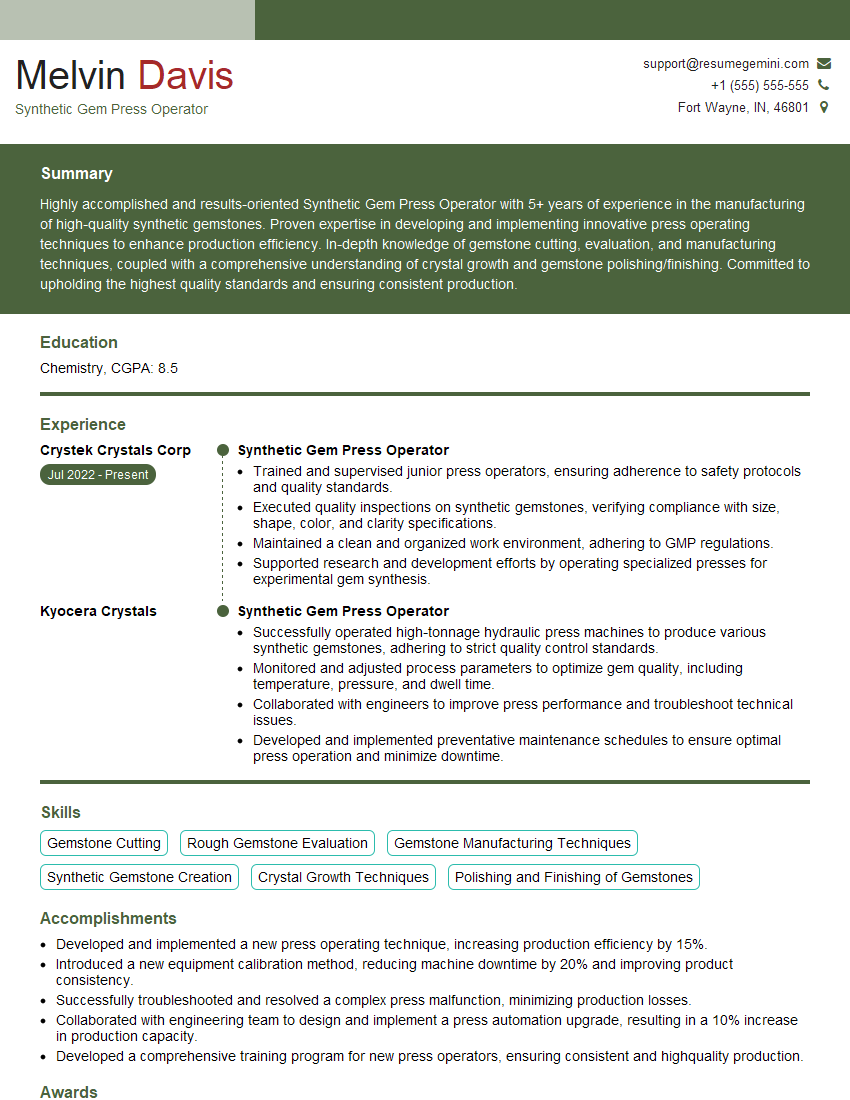

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Synthetic Gem Press Operator

1. Explain the process of synthetic gem pressing?

Synthetic gem pressing involves several key steps:

- Powder Preparation: Raw materials, such as metal oxides and binding agents, are mixed and ground into a fine powder.

- Molding: The powder is placed into a mold and pressed under high pressure to form a pre-form or blank.

- Sintering: The blank is heated to a high temperature, typically between 1200 and 1600 degrees Celsius, to fuse the powder particles together.

- Annealing: The sintered material is cooled slowly to relieve internal stresses and improve its strength.

- Cutting and Polishing: The synthetic gem is cut and polished to achieve its desired shape, size, and clarity.

2. What are the different types of synthetic gems that can be pressed?

Cubic zirconia (CZ)

- Colorless or other colors (e.g., blue, green, red)

- Used in jewelry and industrial applications

Synthetic corundum (ruby, sapphire)

- Range of colors (e.g., red, blue, yellow, pink)

- Used in high-end jewelry and industrial applications

Synthetic spinel

- Wide range of colors

- Used in jewelry and optical applications

3. What are the key parameters to consider when pressing synthetic gems?

- Pressure: Applied during the pressing process, affects the density and strength of the gem.

- Temperature: During sintering, affects the crystal structure and optical properties.

- Atmosphere: Controlled during sintering to prevent oxidation or contamination.

- Cooling rate: During annealing, affects the internal stresses and durability of the gem.

4. How do you ensure the quality of pressed synthetic gems?

- Visual Inspection: Check for cracks, inclusions, color uniformity, and surface finish.

- Optical Characterization: Measure refractive index, dispersion, and clarity.

- Physical Testing: Conduct hardness, toughness, and durability tests.

- Chemical Analysis: Verify the composition and purity of the gem.

5. Describe the safety precautions that must be observed when operating a synthetic gem press?

- Wear protective gear: Including gloves, safety glasses, and a lab coat.

- Handle materials carefully: To avoid cuts or exposure to hazardous chemicals.

- Maintain a clean workspace: To minimize contamination and fire hazards.

- Follow proper operating procedures: As outlined by the manufacturer and industry standards.

6. What troubleshooting steps would you take if the synthetic gem press malfunctions?

- Check the power supply: Ensure that the press is properly connected and receiving power.

- Inspect the hydraulic system: Look for leaks, loose connections, or air bubbles.

- Examine the mold and dies: Check for damage or contamination.

- Calibrate the pressure and temperature sensors: Ensure accuracy and precision.

- Consult the manufacturer’s manual: For specific troubleshooting guidance.

7. How do you maintain and calibrate a synthetic gem press?

- Regular cleaning: Remove dust, debris, and any spilled materials.

- Lubrication: As per manufacturer’s instructions.

- Pressure and temperature calibration: Using certified gauges or equipment.

- Record keeping: Document maintenance and calibration activities.

8. What are the industry trends and advancements in synthetic gem pressing technology?

- Automation: Automated systems for powder mixing, molding, and pressing.

- High-pressure presses: Enabling production of high-density, high-strength gems.

- Advanced materials: Development of new materials and formulations for improved optical and physical properties.

- Sustainability: Exploring environmentally friendly processes and materials.

9. How do you stay up-to-date on the latest developments in the field?

- Attend industry conferences and exhibitions: To network and learn about new technologies.

- Read technical journals and publications: To keep abreast of research and advancements.

- Connect with experts and colleagues: To exchange ideas and collaborate on projects.

10. Why are you interested in this position and why do you believe you are the best candidate?

I am passionate about the science and technology of synthetic gem pressing. I have been working in this field for the past [Number] years, and I have a proven track record of success. I have developed new processes and technologies that have improved the quality and efficiency of gem production. I am also an expert in troubleshooting and maintaining gem presses. I am confident that I have the skills and experience necessary to be successful in this position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Synthetic Gem Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Synthetic Gem Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Synthetic Gem Press Operators play a crucial role in the manufacturing of synthetic gemstones. Their primary responsibilities include:

1. Gemstone Pressing

Operate high-pressure and high-temperature presses to create synthetic gemstones from raw materials.

- Monitor pressure and temperature parameters to ensure optimal conditions for gemstone growth.

- Maintain and calibrate press equipment to ensure accuracy and efficiency.

2. Quality Control

Inspect and evaluate synthetic gemstones for quality and adherence to specifications.

- Identify and resolve defects or imperfections in gemstones.

- Document and maintain records of gemstone production and quality.

3. Equipment Maintenance

Perform routine maintenance and repairs on press equipment.

- Inspect and clean equipment to ensure proper functioning.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

4. Safety and Environment

Follow safety and environmental regulations related to gemstone production.

- Wear appropriate personal protective equipment (PPE) to handle materials and operate machinery.

- Adhere to waste disposal and environmental protection protocols.

Interview Tips

To ace the interview for a Synthetic Gem Press Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and the synthetic gemstone industry.

- Visit the company website and review their latest press releases and financial reports.

- Research industry publications and articles to stay updated on trends and advancements.

2. Highlight Relevant Experience

Emphasize your previous experience in gemstone production or related technical fields.

- Quantify your accomplishments with specific metrics and examples.

- Showcase your familiarity with press equipment, quality control procedures, and safety protocols.

3. Demonstrate Attention to Detail

Synthetic Gem Press Operators need to be meticulous and accurate in their work.

- Provide examples of your ability to follow instructions precisely and maintain high standards.

- Discuss your experience with quality control processes and attention to detail.

4. Emphasize Safety Consciousness

Safety is paramount in gemstone manufacturing. Showcase your commitment to a safe work environment.

- Describe your understanding of safety regulations and your compliance with PPE protocols.

- Share examples of your proactive approach to preventing accidents and incidents.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Synthetic Gem Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Synthetic Gem Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.