Are you gearing up for an interview for a Synthetic Plasterer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Synthetic Plasterer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

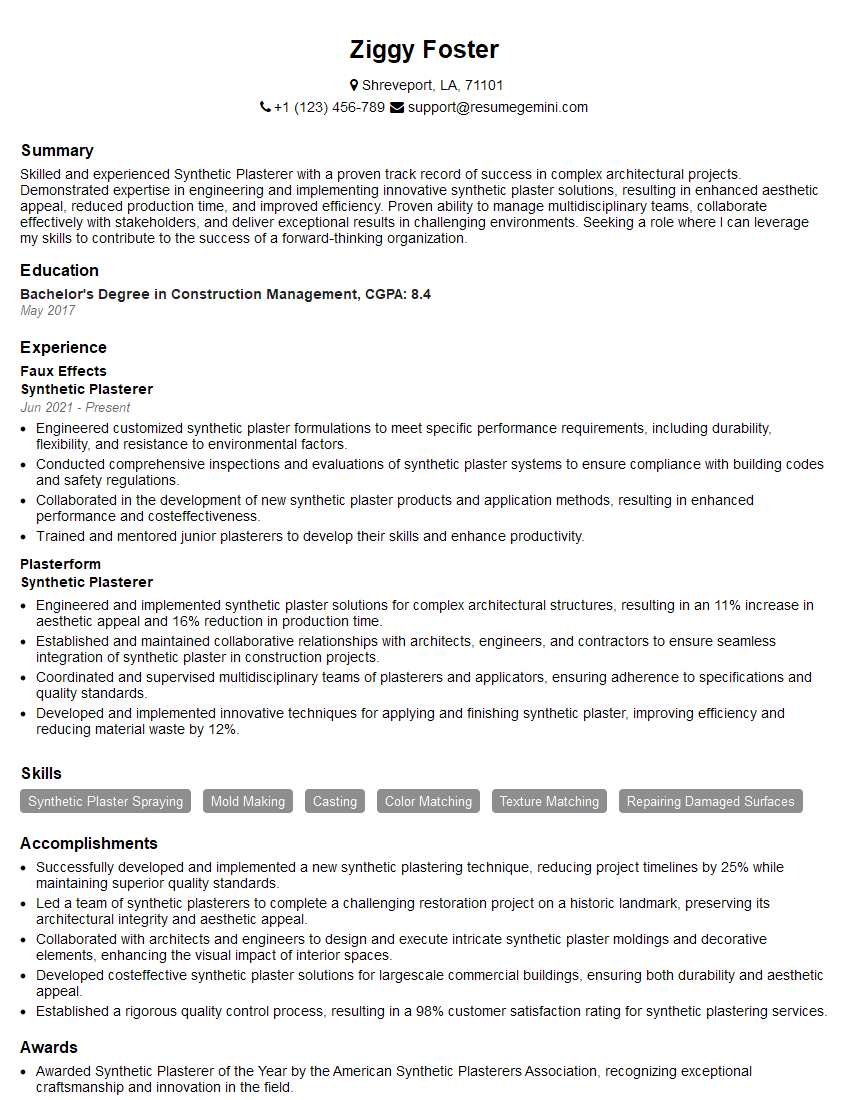

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Synthetic Plasterer

1. What are the different types of synthetic plasters and their applications?

Synthetic plasters are manufactured using synthetic resins and polymers. They are more durable and resistant to wear and tear, making them suitable for use in high-traffic areas or on exterior walls.

- Acrylic plaster: Acrylic plasters are made with acrylic resins and are known for their flexibility and resistance to cracking. They are commonly used for exterior walls, as they can withstand weathering and UV damage.

- Vinyl plaster: Vinyl plasters are made with vinyl resins and are known for their smooth, glossy finish. They are often used for interior walls, as they are easy to clean and maintain.

- Silicone plaster: Silicone plasters are made with silicone resins and are known for their high elasticity and resistance to water and chemicals. They are often used for specialized applications, such as swimming pools or industrial settings.

2. Describe the process of preparing a surface for synthetic plaster application.

Surface preparation

- The surface must be clean, dry, and free of any dirt, grease, or debris.

- Any cracks or holes in the surface should be repaired with a suitable filler.

- The surface should be primed with a bonding agent to ensure good adhesion of the plaster.

Application

- Synthetic plaster is typically applied using a trowel or spray gun.

- The plaster should be applied in a thin, even layer, and any excess should be removed with a trowel.

- The plaster should be allowed to dry for a period of time, depending on the type of plaster used.

3. What are the different techniques used to apply synthetic plaster?

There are two main techniques used to apply synthetic plaster: trowel application and spray application.

- Trowel application: Trowel application is the traditional method of applying synthetic plaster. The plaster is applied using a trowel, and the surface is smoothed and leveled using a float.

- Spray application: Spray application is a faster and more efficient method of applying synthetic plaster. The plaster is sprayed onto the surface using a spray gun, and the surface is then smoothed using a trowel or float.

4. What are the advantages and disadvantages of using synthetic plasters?

Advantages

- Durability: Synthetic plasters are more durable than traditional plasters and are resistant to wear and tear, making them suitable for use in high-traffic areas or on exterior walls.

- Water resistance: Synthetic plasters are water resistant, making them suitable for use in areas that are exposed to moisture, such as bathrooms or kitchens.

- Flexibility: Synthetic plasters are more flexible than traditional plasters, which makes them less likely to crack or chip.

Disadvantages

- Cost: Synthetic plasters are more expensive than traditional plasters.

- Skilled labor: Applying synthetic plasters requires skilled labor, which can be difficult to find.

5. What are the safety precautions that should be taken when working with synthetic plasters?

- Wear appropriate protective gear: When working with synthetic plasters, it is important to wear appropriate protective gear, including gloves, eye protection, and a respirator.

- Work in a well-ventilated area: Synthetic plasters can release harmful fumes, so it is important to work in a well-ventilated area.

- Follow the manufacturer’s instructions: It is important to follow the manufacturer’s instructions for mixing and applying synthetic plasters.

6. What are the different types of finishes that can be achieved with synthetic plasters?

There are a variety of different finishes that can be achieved with synthetic plasters, including:

- Smooth finish: A smooth finish is the most common type of finish for synthetic plasters. It is achieved by applying a thin, even layer of plaster and then smoothing it with a float.

- Textured finish: A textured finish can be achieved by applying a thicker layer of plaster and then using a trowel or sponge to create a textured surface.

- Polished finish: A polished finish can be achieved by applying a thin layer of plaster and then polishing it with a trowel or burnishing tool.

7. What are the common problems that can occur when applying synthetic plasters and how can they be avoided?

There are several common problems that can occur when applying synthetic plasters, including:

- Cracking: Cracking can occur if the plaster is applied too thickly, if the surface is not properly prepared, or if the plaster is not allowed to dry properly.

- Peeling: Peeling can occur if the plaster is not properly bonded to the surface or if the surface is not properly prepared.

- Blistering: Blistering can occur if the plaster is applied to a damp surface or if the surface is not properly prepared.

These problems can be avoided by following the manufacturer’s instructions, by properly preparing the surface, and by allowing the plaster to dry properly.

8. What are the latest trends in synthetic plastering?

There are several latest trends in synthetic plastering, including:

- The use of textured plasters: Textured plasters are becoming increasingly popular, as they can add a unique and stylish look to a space.

- The use of polished plasters: Polished plasters are also becoming increasingly popular, as they can create a smooth, glossy finish that is both stylish and durable.

- The use of sustainable plasters: Sustainable plasters are becoming increasingly popular, as they are made from recycled materials and are more environmentally friendly.

9. What are the qualities of a good synthetic plasterer?

- Skilled: A good synthetic plasterer will be skilled in the application of synthetic plasters and will be able to achieve a high-quality finish.

- Experienced: A good synthetic plasterer will have experience in the application of synthetic plasters and will be able to anticipate and solve problems that may arise.

- Knowledgeable: A good synthetic plasterer will be knowledgeable about the different types of synthetic plasters and their applications, and will be able to advise clients on the best type of plaster for their needs.

10. What is your experience with synthetic plastering?

I have been working as a synthetic plasterer for the past 5 years. During this time, I have gained experience in the application of a variety of different types of synthetic plasters, including acrylic, vinyl, and silicone plasters. I have worked on a variety of different projects, including residential, commercial, and industrial projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Synthetic Plasterer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Synthetic Plasterer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Synthetic Plasterers are responsible for applying synthetic plaster to walls and ceilings in order to create a smooth, decorative finish. Their duties include:

1. Preparing surfaces

Before applying plaster, Synthetic Plasterers must prepare the surfaces by removing old plaster, cleaning away dirt and debris, and repairing any damage. They may also need to apply a bonding agent to help the plaster adhere to the surface.

2. Mixing and applying plaster

Synthetic Plasterers mix the plaster according to the manufacturer’s instructions and then apply it to the surface using a trowel. They must work quickly and evenly to ensure that the plaster is applied smoothly and without any lumps or bumps.

3. Finishing the surface

Once the plaster has been applied, Synthetic Plasterers must finish the surface by smoothing it out with a trowel and then sanding it to remove any imperfections. They may also need to apply a paint or sealant to protect the plaster from damage.

4. Cleaning up

After finishing the job, Synthetic Plasterers must clean up their work area and dispose of any waste materials.

Interview Tips

Preparing for a Synthetic Plasterer interview can be daunting, but with the right tips, you can increase your chances of success. Here are a few things you can do to prepare:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a candidate.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Synthetic Plasterer. Be prepared to discuss your past projects, your techniques, and your attention to detail. You should also be able to explain how your skills and experience make you the ideal candidate for the position.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are taking the interview seriously.

Next Step:

Now that you’re armed with the knowledge of Synthetic Plasterer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Synthetic Plasterer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini