Feeling lost in a sea of interview questions? Landed that dream interview for Synthetic Soil Blocks Pulper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Synthetic Soil Blocks Pulper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

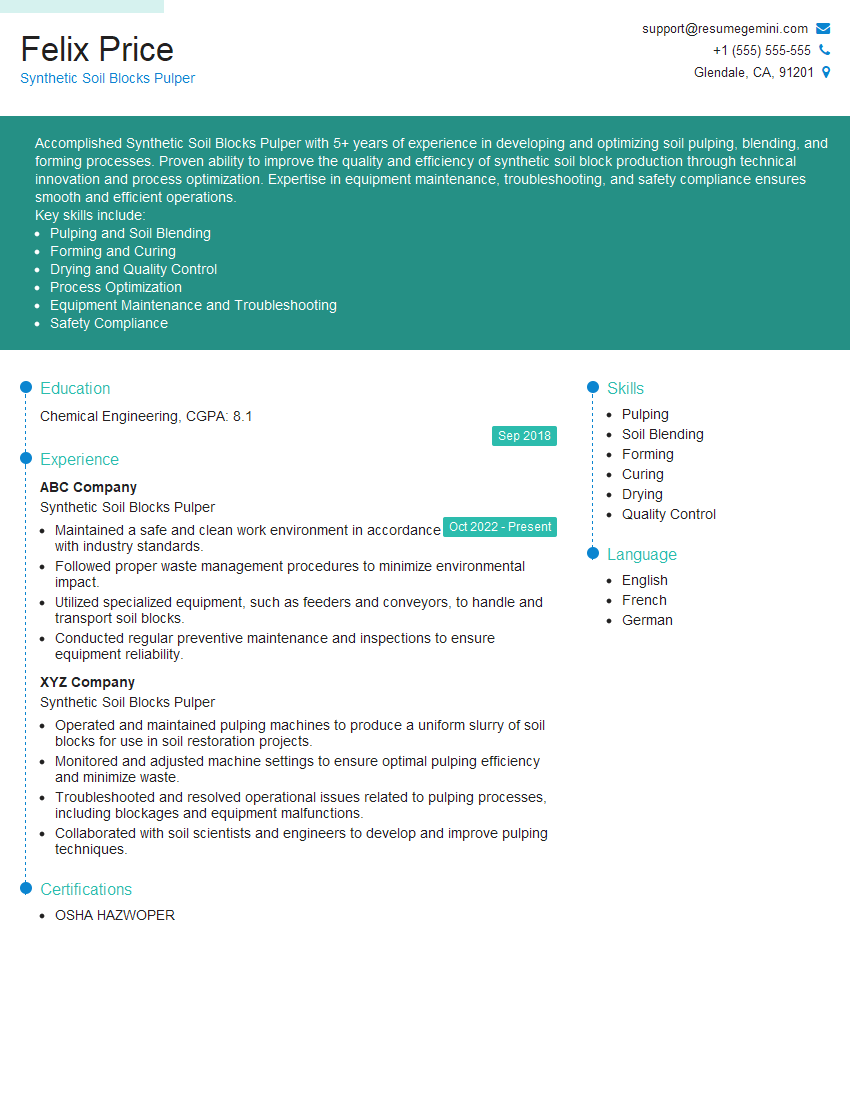

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Synthetic Soil Blocks Pulper

1. Explain the key components of a Synthetic Soil Blocks Pulper and their functions.

The main components of a Synthetic Soil Blocks Pulper are:

- Pulping chamber: Where the soil, water, and additives are mixed to form a pulp.

- Mixing blades: Rotate to mix the ingredients thoroughly and create a uniform pulp.

- Discharge chute: Allows the pulp to be discharged into molds or containers.

- Control panel: Used to adjust the operating parameters of the pulper, such as mixing speed and water flow.

2. Describe the process of pulping synthetic soil blocks.

Mixing

- Load the soil, water, and additives into the pulping chamber.

- Start the mixing blades and mix the ingredients until a uniform pulp is formed.

Discharge

- Open the discharge chute and allow the pulp to flow out into molds or containers.

- The molds or containers are then placed in a drying area to allow the soil blocks to cure.

3. What factors should be considered when selecting the appropriate type of Synthetic Soil Blocks Pulper for a particular application?

- Capacity: The volume of pulp that the pulper can produce per hour.

- Mixing speed: The speed at which the mixing blades rotate.

- Water flow rate: The rate at which water is added to the pulping chamber.

- Power requirements: The amount of power required to operate the pulper.

- Size and weight: The physical dimensions and weight of the pulper.

4. What are the common maintenance tasks associated with Synthetic Soil Blocks Pulpers?

- Cleaning: Regularly clean the pulping chamber, mixing blades, and discharge chute to prevent buildup of soil and additives.

- Inspection: Inspect the pulper regularly for signs of wear or damage.

- Lubrication: Lubricate the moving parts of the pulper as per the manufacturer’s instructions.

- Calibration: Calibrate the control panel to ensure accurate operation.

5. Describe the safety precautions that should be taken when operating a Synthetic Soil Blocks Pulper.

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, and a dust mask.

- Keep hands and body away from moving parts: The mixing blades can cause serious injury.

- Do not operate the pulper if it is damaged or malfunctioning: Have it inspected and repaired by a qualified technician.

- Follow the manufacturer’s instructions: Refer to the user manual for specific safety guidelines.

6. What are the advantages of using synthetic soil blocks over traditional soil blocks?

- Consistency: Synthetic soil blocks are manufactured under controlled conditions, ensuring consistent quality and performance.

- Durability: Synthetic soil blocks are more durable than traditional soil blocks and can withstand harsh weather conditions.

- Lightweight: Synthetic soil blocks are lighter than traditional soil blocks, making them easier to transport and handle.

- Cost-effective: Synthetic soil blocks can be more cost-effective than traditional soil blocks, especially in large-scale applications.

7. What are the applications of synthetic soil blocks?

- Erosion control: Synthetic soil blocks can be used to stabilize slopes and prevent soil erosion.

- Landscaping: Synthetic soil blocks can be used to create raised beds, planters, and other landscaping features.

- Urban greening: Synthetic soil blocks can be used to create green roofs and walls in urban areas.

- Agriculture: Synthetic soil blocks can be used to improve soil fertility and crop yields.

8. What is the future of synthetic soil blocks technology?

- Increased use of recycled materials: Synthetic soil blocks are becoming more sustainable by incorporating recycled materials into their composition.

- Customizable properties: Researchers are developing synthetic soil blocks with customizable properties, such as water retention and nutrient release.

- Integration with smart technologies: Synthetic soil blocks are being integrated with sensors and other smart technologies to monitor soil conditions and optimize plant growth.

- Expanded applications: Synthetic soil blocks are being explored for new applications, such as bioremediation and carbon sequestration.

9. How do you stay up-to-date on the latest advancements in synthetic soil blocks technology?

- Attend industry conferences and workshops: These events provide opportunities to learn about new technologies and network with experts.

- Read technical journals and articles: Stay informed about the latest research and developments in the field.

- Join professional organizations: Connect with other professionals and gain access to resources and information.

- Follow industry news and trends: Keep up with the latest advancements through online news sources and social media.

10. What are your strengths and weaknesses as a Synthetic Soil Blocks Pulper?

My strengths include:

- Extensive knowledge of synthetic soil blocks technology: I have a deep understanding of the principles, materials, and applications of synthetic soil blocks.

- Experience in operating and maintaining pulpers: I have hands-on experience in operating and maintaining various types of synthetic soil blocks pulpers.

- Strong troubleshooting skills: I am able to identify and resolve problems quickly and efficiently.

My weaknesses include:

- Limited experience in large-scale production: I have primarily worked in small-scale synthetic soil blocks production facilities.

- Need to improve communication skills: I am working on developing my communication skills to be able to effectively convey technical information to non-technical audiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Synthetic Soil Blocks Pulper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Synthetic Soil Blocks Pulper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Synthetic Soil Blocks Pulper is responsible for operating and maintaining the soil block pulping machine to produce high-quality synthetic soil blocks. The key job responsibilities include:

1. Operation of Soil Block Pulping Machine

intro paragraph

- Set up and calibrate the soil block pulping machine according to established procedures.

- Monitor the machine’s operation to ensure proper functioning and efficiency.

- Adjust machine settings to optimize soil block quality and productivity.

- Troubleshoot and resolve any issues that arise during the pulping process.

2. Soil Block Production

intro paragraph

- Inspect raw materials and ensure they meet quality standards.

- Load raw materials into the pulping machine.

- Monitor the pulping process to ensure consistent soil block quality.

- Collect and inspect produced soil blocks to verify conformity to specifications.

3. Quality Control

intro paragraph

- Perform regular quality checks on soil blocks to ensure they meet established standards.

- Document and report any quality issues or deviations to supervisors.

- Implement corrective actions to maintain soil block quality and consistency.

4. Machine Maintenance

intro paragraph

- Perform routine maintenance on the soil block pulping machine.

- Clean and lubricate machine components.

- Identify and report any potential maintenance issues to supervisors.

- Assist with major repairs and overhauls as needed.

Interview Tips

To ace the interview for the Synthetic Soil Blocks Pulper position, follow these interview tips and hacks:

1. Research the Company and Role

intro paragraph

- Thoroughly research the company, its products and services, and the specific role you are applying for.

- This will help you understand the company’s culture, goals, and the specific responsibilities of the position.

2. Highlight Relevant Skills and Experience

intro paragraph

- In your resume and during the interview, emphasize your relevant skills and experience, including any experience in soil block production, machine operation, quality control, or maintenance.

- Provide specific examples of your accomplishments in these areas.

3. Demonstrate Problem-Solving Abilities

intro paragraph

- Interviewers will be interested in your problem-solving abilities, particularly in the context of soil block production.

- Be prepared to discuss how you would handle common challenges or unexpected situations that may arise during the pulping process.

4. Show Your Commitment to Quality

intro paragraph

- Emphasize your commitment to producing high-quality soil blocks that meet established standards.

- Explain your understanding of quality control procedures and how you ensure consistent soil block quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Synthetic Soil Blocks Pulper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.