Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Syrup Shed Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

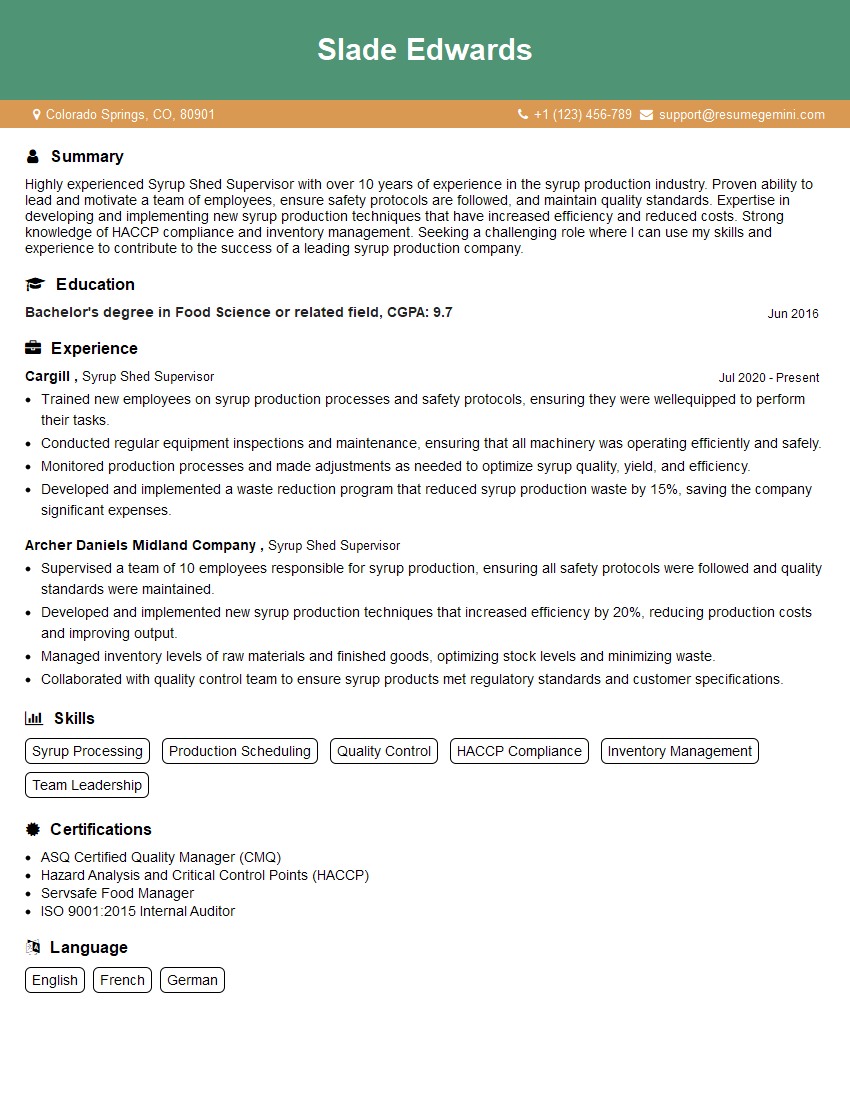

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Syrup Shed Supervisor

1. Describe the processes involved in syrup production at your previous workplace.

In my previous role, syrup production entailed several key processes:

- Raw material inspection: Examining incoming raw materials, such as corn or cane sugar, for quality and adherence to specifications.

- Milling and extraction: Breaking down raw materials into a fine consistency and extracting the sugary liquid.

- Clarification and filtration: Removing impurities and particles from the extracted liquid through sedimentation, filtration, and activated carbon treatment.

- Evaporation: Concentrating the clarified liquid by removing water through heat evaporation.

- Crystallization: Inducing the formation of sugar crystals in a controlled environment.

- Centrifugation: Separating the sugar crystals from the syrup.

- Storage and packaging: Storing and packaging the finished syrup in appropriate containers for distribution.

2. Explain the principles of brewing and how they apply to syrup production.

Brewing Principles

- Extraction: Dissolving soluble components from solid materials into a liquid.

- Fermentation: Converting sugars into alcohol by yeast.

- Maturation: Aging the brewed product to enhance flavor and aroma.

Application to Syrup Production

- Extraction: Extracting sugars from raw materials using water or other solvents.

- Fermentation: Not applicable in syrup production.

- Maturation: Aging syrups for a short period to allow flavor components to develop.

3. Discuss the importance of maintaining a sterile environment in syrup production.

Maintaining a sterile environment is crucial in syrup production to prevent contamination and ensure product safety:

- Prevents spoilage: Sterilization eliminates microorganisms that can cause spoilage, extending the shelf life of syrup.

- Protects consumers: Sterile conditions minimize the risk of pathogenic bacteria entering the syrup, protecting consumers from foodborne illnesses.

- Maintains product quality: Contamination can alter the flavor, color, and consistency of syrup, affecting its overall quality.

- Complies with regulations: Many countries have strict regulations governing food safety, including syrup production.

4. Describe the different types of equipment used in syrup production and their functions.

Syrup production utilizes various types of equipment, each serving a specific function:

- Milling machines: Break down raw materials into smaller particles.

- Extractors: Separate sugar-containing liquid from raw materials.

- Clarifiers and filters: Remove impurities from the extracted liquid.

- Evaporators: Concentrate the liquid by removing water.

- Crystallizers: Induce sugar crystal formation.

- Centrifuges: Separate sugar crystals from syrup.

- Storage tanks: Hold finished syrup before packaging.

5. Explain the role of quality control in syrup production.

Quality control plays a vital role in syrup production by ensuring:

- Product safety: Testing syrup for microbial contamination and compliance with food safety standards.

- Consistency: Monitoring syrup properties such as density, sweetness, and color to maintain consistent quality.

- Customer satisfaction: Meeting customer expectations by producing syrup that meets their desired specifications.

- Regulatory compliance: Adhering to industry regulations and standards for syrup production.

6. Describe the challenges faced in syrup production and how you would overcome them.

Common challenges in syrup production include:

- Raw material variability: Fluctuations in raw material quality can affect syrup yield and consistency.

- Microbial contamination: Maintaining a sterile environment is crucial to prevent spoilage and ensure product safety.

- Crystallization control: Managing crystallization conditions is essential to achieve the desired crystal size and texture.

To overcome these challenges, I would:

- Implement rigorous quality control measures: Establish stringent protocols for raw material inspection, process monitoring, and finished product testing.

- Optimize sanitation and hygiene practices: Regularly clean and disinfect equipment, maintain a sterile work environment, and train employees on proper sanitation procedures.

- Conduct research and development: Explore innovative techniques to improve crystallization control and minimize the impact of raw material variability.

7. Discuss the environmental considerations in syrup production.

Environmental considerations in syrup production include:

- Water conservation: Implementing water-efficient technologies and recycling water during processing.

- Waste minimization: Reducing waste by optimizing processes and finding alternative uses for byproducts.

- Energy efficiency: Utilizing energy-efficient equipment, optimizing production schedules, and implementing renewable energy sources.

8. Explain the importance of teamwork and communication in syrup production.

Teamwork and communication are essential in syrup production for:

- Effective operations: Collaborating with colleagues to ensure smooth production processes and quick resolution of issues.

- Knowledge sharing: Exchanging ideas and expertise to improve production techniques and troubleshoot problems.

- Safety compliance: Communicating safety protocols and procedures to ensure a safe work environment for all employees.

9. Describe your approach to training and development in syrup production.

My approach to training and development in syrup production involves:

- Identifying training needs: Conducting assessments to determine knowledge gaps and skill deficiencies among employees.

- Developing training programs: Creating tailored training modules that cover technical aspects of syrup production, quality control procedures, and safety protocols.

- Delivering training: Utilizing various training methods, such as hands-on demonstrations, simulations, and online learning platforms.

- Evaluating training effectiveness: Assessing the impact of training programs by monitoring performance improvements and feedback from employees.

10. Explain how you would motivate and engage your team in syrup production.

To motivate and engage my team in syrup production, I would:

- Foster a positive work environment: Creating a respectful and supportive workplace where employees feel valued and appreciated.

- Set clear goals and expectations: Communicating performance objectives, providing regular feedback, and recognizing achievements.

- Encourage continuous improvement: Promoting a culture of learning and innovation, empowering employees to suggest improvements and take ownership of their work.

- Provide opportunities for professional development: Offering training, mentoring, and career advancement opportunities to enhance employee skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Syrup Shed Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Syrup Shed Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Syrup Shed Supervisor is accountable for overseeing the operations of the syrup shed, ensuring the efficient production and quality of syrup while maintaining a safe and compliant work environment.

1. Manage Production

The supervisor is responsible for planning, organizing, and directing the production of syrup, ensuring adherence to production schedules and quality standards.

- Develop and implement production plans to optimize output and meet demand.

- Monitor production processes, identify bottlenecks, and implement corrective actions to improve efficiency.

2. Quality Control

The supervisor is accountable for ensuring the quality of the syrup produced, conducting regular inspections and implementing quality control measures.

- Establish quality standards and conduct regular inspections to ensure compliance.

- Identify and resolve quality issues, implementing corrective actions to prevent recurrences.

3. Safety and Compliance

The supervisor is responsible for maintaining a safe and compliant work environment, adhering to all safety regulations and industry standards.

- Develop and implement safety protocols, ensuring compliance with all applicable regulations.

- Conduct regular safety inspections and provide training to staff on safe work practices.

4. Team Leadership

The supervisor leads a team of operators and oversees their performance, providing training, support, and motivation.

- Recruit, train, and develop team members, ensuring they are proficient in syrup production operations.

- Motivate and inspire the team to achieve production goals and maintain high quality standards.

Interview Tips

To ace the interview for a Syrup Shed Supervisor position, here are some preparation tips and hacks:

1. Research the Company and Role

Gather information about the company’s syrup production operations, industry trends, and specific requirements of the role.

- Visit the company website, read industry publications, and connect with professionals in the field.

- Prepare questions that demonstrate your understanding of the company and the position.

2. Highlight Relevant Skills and Experience

Emphasize your skills in production planning, quality control, safety management, and team leadership.

- Quantify your accomplishments and provide specific examples of how you have improved syrup production processes.

- Demonstrate your ability to identify and resolve quality issues, ensuring compliance with industry standards.

3. Prepare for Behavioral Interview Questions

Interviewers often use behavioral interview questions to assess your problem-solving abilities, teamwork skills, and commitment to safety.

- Use the STAR method (Situation, Task, Action, Result) to answer these questions, providing detailed examples.

- Focus on situations where you faced challenges, took initiative, and achieved positive outcomes.

4. Practice Your Answers

Practice answering common interview questions out loud to improve your delivery and confidence.

- Seek feedback from a friend, family member, or career counselor to refine your answers.

- Time yourself to ensure you can provide concise and articulate responses within the time limit.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Syrup Shed Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.