Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Table Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

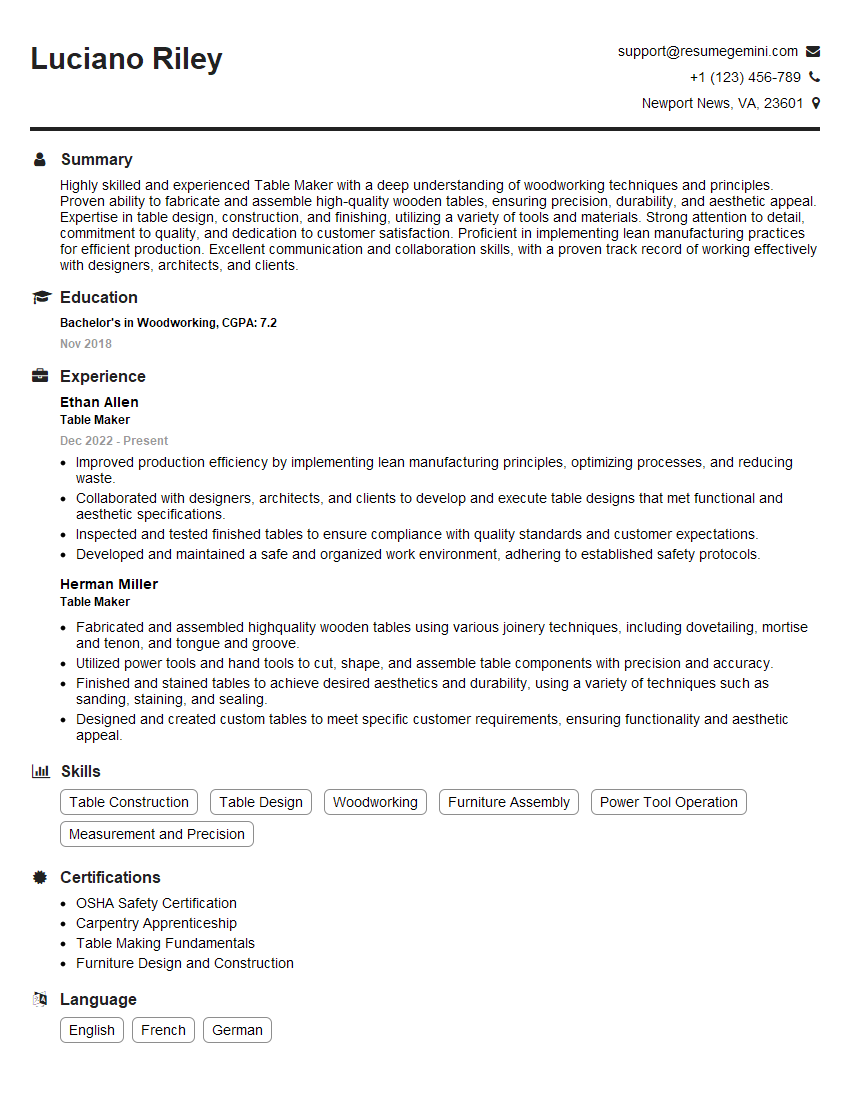

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Table Maker

1. Briefly describe the key steps involved in making a high-quality table?

- Gather requirements and specifications from the client.

- Design the table, including the number of rows, columns, and overall layout.

- Select the appropriate materials for the table, such as wood, metal, or plastic.

- Cut and shape the materials to the desired dimensions.

- Assemble the table, ensuring that it is sturdy and stable.

- Sand and finish the table to give it a smooth and polished appearance.

- Inspect the table to ensure that it meets all of the quality standards.

2. What are the different types of joinery techniques used in table making?

Mortise and tenon joint

- Strong and durable joint that is often used to connect the legs to the tabletop.

- Made by cutting a mortise (a square hole) into one piece of wood and a tenon (a protruding tongue) into another piece of wood.

- The tenon is then inserted into the mortise and secured with glue or pegs.

Dowel joint

- Simple and quick to make joint that is often used to connect smaller pieces of wood.

- Made by drilling a hole in each piece of wood and inserting a dowel (a cylindrical piece of wood).

- The dowel is then secured with glue or epoxy.

Biscuit joint

- Strong and versatile joint that is often used to connect large pieces of wood.

- Made by cutting a slot in each piece of wood and inserting a biscuit (a thin, oval-shaped piece of wood).

- The biscuit is then secured with glue or epoxy.

3. What are the key factors to consider when selecting the right wood for a table?

- Type of table: The type of table will determine the required strength, durability, and appearance of the wood.

- Budget: The cost of the wood will vary depending on the species, grade, and thickness.

- Grain pattern: The grain pattern of the wood will affect the appearance of the table.

- Durability: The durability of the wood will depend on its resistance to rot, decay, and insects.

- Availability: The availability of the wood will depend on the location and the time of year.

4. What are the different types of table finishes?

- Oil finish: Oil finishes are easy to apply and provide a natural look.

- Varnish finish: Varnish finishes are more durable than oil finishes and provide a glossy appearance.

- Lacquer finish: Lacquer finishes are the most durable of all finishes and provide a high-gloss appearance.

- Shellac finish: Shellac finishes are a type of natural finish that is made from the secretions of the lac insect.

5. What are the most common problems that you encounter when making tables?

- Uneven legs: Uneven legs can cause the table to wobble.

- Loose joints: Loose joints can weaken the table and cause it to collapse.

- Split wood: Split wood can occur if the wood is not properly seasoned or if it is subjected to too much stress.

- Warping: Warping can occur if the wood is not properly dried or if it is exposed to moisture.

- Finish problems: Finish problems can occur if the finish is not properly applied or if it is not compatible with the wood.

6. What are the latest trends in table design?

- Live edge tables: Live edge tables are made from slabs of wood that have been left with their natural edges.

- Reclaimed wood tables: Reclaimed wood tables are made from wood that has been salvaged from old buildings or other structures.

- Floating tables: Floating tables are tables that appear to be suspended in mid-air.

- Multi-functional tables: Multi-functional tables are tables that can be used for multiple purposes, such as dining, working, or storage.

7. What steps do you take to ensure the quality of your tables?

- Use high-quality materials

- Follow best practices in joinery and finishing

- Inspect each table before it leaves the workshop

- Stand behind my work with a satisfaction guarantee

8. What is your favorite type of table to make?

- Here you can describe your favorite type of table to make and why you enjoy making it.

9. What are your strengths as a table maker?

- Here you can highlight your strengths as a table maker, such as your attention to detail, your craftsmanship, and your ability to meet deadlines.

10. What are your weaknesses as a table maker?

- Here you can acknowledge your weaknesses as a table maker, but be sure to frame them in a positive light. For example, you could say that you are always looking for ways to improve your skills and that you are open to feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Table Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Table Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Table Maker is responsible for creating, assembling, and maintaining tables, as well as ensuring that they are in good working condition. Their duties include:intro paragraph

1. Building tables

Table makers often begin their work by reading blueprints, or other design documents, to determine the type of table that will need to be built. Then, they meticulously cut and assemble the individual components of the table, taking care to ensure that the finished product is both sturdy and aesthetically pleasing.

- Cutting and shaping wood or other materials to create table components

- Assembling table components using nails, screws, or other fasteners

2. Repairing and maintaining tables

Table makers possess a knack for identifying and resolving problems with tables. This may involve repairing damaged components, such as legs or tops, or performing routine maintenance tasks, such as tightening loose screws. In some cases, they may also be responsible for refinishing or reupholstering tables to restore their original appearance.

- Identifying and repairing damaged table components

- Performing routine maintenance tasks, such as tightening loose screws or lubricating moving parts

- Refinishing or reupholstering tables to restore their original appearance

3. Designing tables

Table makers are often involved in the design process for new tables. They may work with clients to determine the desired style, size, and functionality of the table, and then create a design that meets those specifications. In some cases, they may also be responsible for creating prototypes of new table designs.

- Working with clients to determine the desired style, size, and functionality of a table

- Creating a design for a new table

- Creating prototypes of new table designs

Interview Tips

Attending an interview for a Table Maker position requires preparation and confidence. Having a clear understanding of your skills and experience related to this role, as well as practicing your answers to common interview questions, will help you ace the interview and secure the opportunity to showcase your expertise. Here are some additional tips to help you prepare and ace your interview:

1. Research the company

Prior to your interview, take the time to learn more about the company you are applying to. This will give you a better understanding of their products or services, their values, the work culture, and the potential growth opportunities within the organization.

2. Practice your answers to common interview questions

Consider the questions the interviewer may ask and prepare your answers to ensure they highlight your relevant skills and experience effectively. Additionally, your answers must align with the company’s requirements and values. Practicing your answers in advance can help you deliver them confidently and concisely during the interview.

- Tell us about your experience as a Table Maker.

- What are your strengths and weaknesses as a Table Maker?

- Why are you interested in working for our company?

- What are your salary expectations?

- Do you have any questions for us?

3. Highlight your technical skills

Emphasize your expertise in carpentry, table assembly techniques, and overall craftsmanship during the interview. Providing specific examples of your adeptness in using tools and equipment, such as saws, drills, and sanders, will demonstrate your technical proficiency.

4. Showcase your creativity and attention to detail

Highlight your creativity and meticulousness in designing and building tables, as these qualities are highly valued in Table Makers. Share instances where you went above and beyond to create unique and visually appealing tables, paying attention to details and ensuring impeccable craftsmanship.

5. Convey your passion for the craft

Express your genuine enthusiasm and appreciation for creating tables. Explain how you find satisfaction in the process of transforming raw materials into functional and aesthetically pleasing furniture pieces. Your passion for the craft will resonate with the interviewer and demonstrate your dedication to the profession.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Table Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Table Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.