Are you gearing up for a career in Table Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Table Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

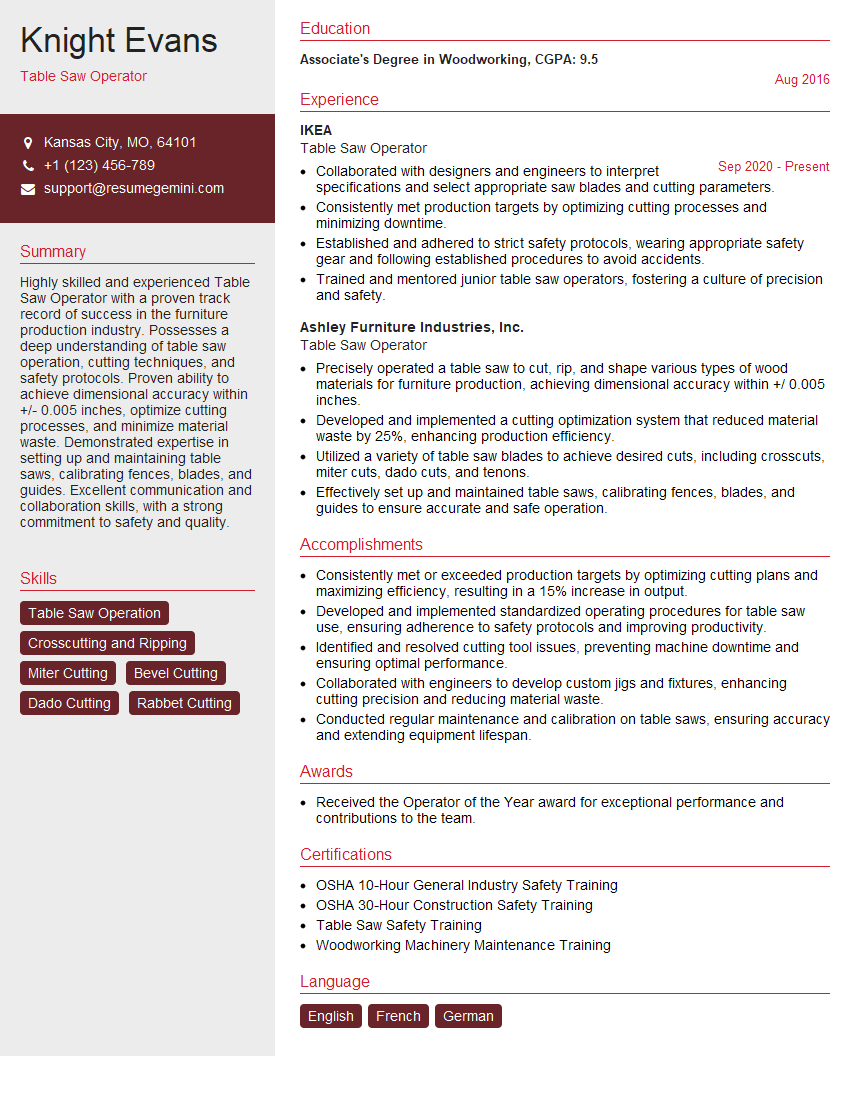

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Table Saw Operator

1. Describe the steps involved in setting up and operating a table saw?

- Inspect the table saw to ensure it is in good working condition and free from defects.

- Attach the appropriate blade for the type of cut being made.

- Adjust the blade height and angle.

- Set the fence and miter gauge to the desired measurements.

- Secure the workpiece to the table using clamps or a miter gauge.

- Check the saw blade guard and riving knife to ensure they are properly positioned.

- Turn on the saw and carefully guide the workpiece through the blade.

2. What safety precautions should be taken when operating a table saw?

- Always wear appropriate safety gear, including eye protection, hearing protection, and work gloves.

- Keep hands away from the blade at all times.

- Never operate the saw under the influence of drugs or alcohol.

- Use a push stick or push block to guide the workpiece through the blade.

- Be aware of the location of the blade guard and riving knife at all times.

- Inspect the saw regularly for any signs of damage or wear and tear.

3. How do you determine the correct blade speed and feed rate for a given material?

- Refer to the manufacturer’s recommendations for the specific material being cut.

- Consider the thickness and hardness of the material.

- Start with a low blade speed and feed rate and gradually increase them as needed.

- Listen for any unusual noises or vibrations that may indicate the blade speed or feed rate is too high.

4. Describe the different types of table saw blades and their uses.

- Ripping blades: Designed for cutting along the grain of the wood.

- Crosscut blades: Designed for cutting across the grain of the wood.

- Dado blades: Designed for cutting wide grooves or dadoes.

- Combination blades: Designed for both ripping and crosscutting.

5. How do you troubleshoot common problems with a table saw?

- Blade not cutting cleanly: The blade may be dull or damaged, or the workpiece may not be secured properly.

- Saw blade wobbling: The blade may be loose or warped, or the arbor may be damaged.

- Saw not cutting straight: The fence or miter gauge may be misaligned, or the workpiece may not be held securely.

- Saw overheating: The blade may be dull or damaged, or the saw may be overloaded.

6. What maintenance procedures are required for a table saw?

- Clean the saw regularly, removing any sawdust or debris.

- Lubricate the saw’s moving parts, such as the blade arbor and fence rails.

- Inspect the saw blade for signs of wear or damage, and replace it if necessary.

- Check the electrical cords and connections for any damage.

7. Describe the different types of jointing procedures used in table saw joinery.

- Edge jointing: Aligning the edges of two pieces of wood to create a straight, even joint.

- Face jointing: Leveling the surface of a piece of wood to create a flat, smooth surface.

- Miter jointing: Cutting two pieces of wood at an angle and joining them together to create a corner.

- Dado jointing: Cutting a groove in one piece of wood and fitting a second piece of wood into the groove to create a strong, concealed joint.

8. What factors should be considered when selecting a table saw?

- Blade size and power: Determines the thickness and types of materials that can be cut.

- Table size: Determines the size of workpieces that can be handled.

- Fence system: Determines the accuracy and precision of cuts.

- Miter gauge: Determines the accuracy and precision of angled cuts.

- Safety features: Includes blade guard, riving knife, and anti-kickback pawls.

9. How do you calculate the blade speed of a table saw?

10. What is a dado stack and how is it used?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Table Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Table Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Table Saw Operators play a crucial role in various industries, particularly woodworking and manufacturing. Their key responsibilities include:

1. Table Saw Operation

Safely and efficiently operate table saws to cut, shape, and size various materials, primarily wood.

- Interpret blueprints and cutting lists to determine the required cuts and measurements.

- Adjust table saw settings, blades, and fences to achieve precise cuts.

2. Material Handling

Handle and move large and heavy pieces of material, such as lumber and plywood, with caution.

- Use proper lifting techniques and tools to avoid injury.

- Check materials for defects and ensure they meet specifications.

3. Maintenance and Troubleshooting

Maintain and troubleshoot table saws and related equipment to ensure optimal performance and safety.

- Perform regular inspections and cleaning to prevent breakdowns.

- Identify and resolve common issues, such as blade dullness or fence alignment.

4. Compliance and Safety

Adhere to all safety regulations and guidelines related to table saw operation and workplace safety.

- Wear appropriate protective gear, including eye protection, earplugs, and gloves.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Table Saw Operator position, consider the following tips:

1. Research and Preparation

Research the company and the specific industry you’re applying to. Familiarize yourself with their products, services, and safety protocols.

- Practice common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Review the job description thoroughly to identify key responsibilities and requirements.

2. Highlight Safety and Attention to Detail

Emphasize your commitment to safety and attention to detail. Table saw operation requires precision and adherence to safety guidelines.

- Discuss your understanding of proper blade selection, fencing, and other safety measures.

- Provide examples of how you have maintained a safe work environment in previous roles.

3. Demonstrate Technical Knowledge

Showcase your technical knowledge and understanding of table saw operation. This includes blade types, cutting techniques, and material handling.

- Explain how you determine the correct blade for different materials and cutting purposes.

- Describe your experience with various table saw setups and adjustments.

4. Physical and Lifting Capacity

Be prepared to discuss your physical and lifting capacity, as table saw operators often handle heavy materials.

- Highlight your ability to lift and move heavy objects safely.

- Explain any physical limitations that may impact your ability to perform the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Table Saw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!