Feeling lost in a sea of interview questions? Landed that dream interview for Tablet Making Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tablet Making Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

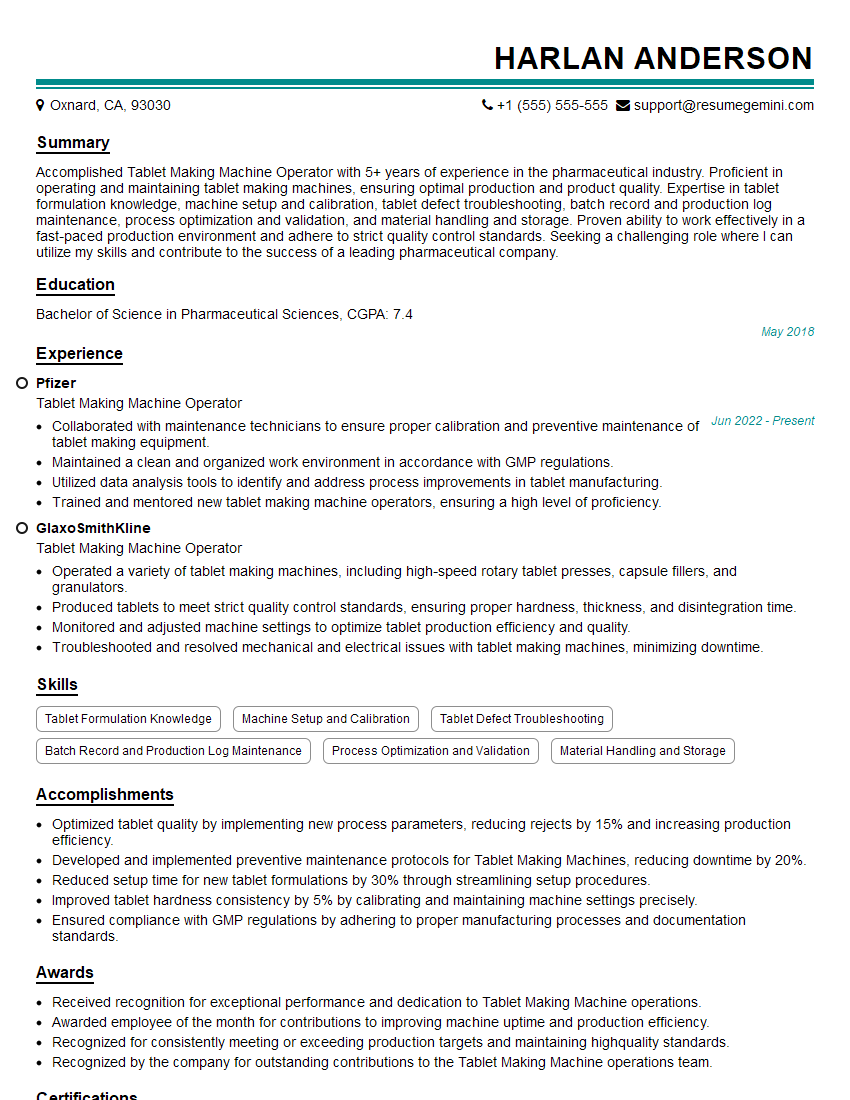

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tablet Making Machine Operator

1. What are the different types of tablet machines?

There are two main types of tablet machines: single-station and multi-station.

- Single-station machines produce one tablet at a time, while multi-station machines can produce multiple tablets simultaneously.

- Multi-station machines are more efficient and can produce higher volumes of tablets, but they are also more expensive than single-station machines.

2. What are the key components of a tablet machine?

Feeding System

- Hopper

- Feeder

Compression System

- Dies and punches

- Cam track

- Turret

Ejection System

- Ejector pins

- Ejection cam

Dust Collection System

- Dust collector

- Filters

3. How do you set up and calibrate a tablet machine?

The setup and calibration of a tablet machine is a complex process that requires specialized knowledge and training.

- The first step is to install the dies and punches into the machine.

- The next step is to adjust the cam track and turret to ensure that the dies and punches are properly aligned.

- Once the machine is set up, it must be calibrated to ensure that it is producing tablets of the correct weight and thickness.

4. What are the common problems that can occur with tablet machines?

- Tablet sticking to the punches

- Tablet capping

- Tablet lamination

- Tablet weight variation

- Tablet thickness variation

5. How do you troubleshoot and resolve common tablet machine problems?

Troubleshooting and resolving tablet machine problems requires a combination of technical knowledge and experience.

- The first step is to identify the problem.

- Once the problem has been identified, the next step is to find the root cause.

- Once the root cause has been identified, the next step is to implement a solution.

6. What are the safety precautions that must be followed when operating a tablet machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Keep the work area clean and free of debris.

- Do not operate the machine if it is not properly set up and calibrated.

- Do not reach into the machine while it is running.

- Follow all manufacturer’s instructions for safe operation.

7. What is the role of quality control in tablet manufacturing?

Quality control is essential in tablet manufacturing to ensure that the tablets meet the required specifications.

- Quality control involves testing the tablets for weight, thickness, hardness, and dissolution.

- Quality control also involves inspecting the tablets for defects, such as cracks, chips, and discoloration.

8. What are the different types of tablet coatings?

- Sugar coating

- Film coating

- Enteric coating

- Sustained-release coating

9. What are the advantages and disadvantages of different tablet coatings?

Sugar Coating

- Advantages: Aesthetically pleasing, protects against moisture

- Disadvantages: Time-consuming, can be difficult to control

Film Coating

- Advantages: Easy to apply, provides a uniform coating

- Disadvantages: Can be expensive, may not be suitable for all tablets

Enteric Coating

- Advantages: Protects against stomach acid, allows for targeted drug delivery

- Disadvantages: Can be difficult to apply, may not be suitable for all tablets

Sustained-Release Coating

- Advantages: Controls drug release rate, improves patient compliance

- Disadvantages: Can be complex to develop, may not be suitable for all tablets

10. What are the latest trends in tablet manufacturing?

- Continuous manufacturing

- 3D printing

- Personalized medicine

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tablet Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tablet Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tablet Making Machine Operators are responsible for operating and maintaining tablet making machines used in the production of pharmaceutical products. They ensure that the machines are running smoothly and efficiently, and that the tablets are produced according to specifications.

1. Machine Operation

Operate and monitor tablet making machines to produce tablets in accordance with prescribed specifications.

- Set up and adjust machine parameters, including tablet weight, hardness, and dimensions.

- Monitor machine performance and make necessary adjustments to maintain optimal production.

2. Quality Control

Perform quality control checks on tablets to ensure they meet required standards.

- Inspect tablets for physical defects, such as cracks, chips, or discoloration.

- Take samples and conduct laboratory tests to verify tablet properties, such as hardness, disintegration time, and dissolution rate.

3. Maintenance and Troubleshooting

Maintain and troubleshoot tablet making machines to prevent breakdowns and ensure efficient operation.

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve machine malfunctions, including electrical, mechanical, and software issues.

4. Production Planning and Scheduling

Assist in production planning and scheduling to ensure timely delivery of tablets.

- Review production orders and determine machine setup and changeover requirements.

- Coordinate with production supervisors to schedule machine downtime for maintenance and repairs.

Interview Tips

Preparing adequately for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Tablet Making Machine Operator position:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by thoroughly researching the company and the specific role. Understand their products, values, and industry standing. This knowledge will enable you to tailor your answers and show that you are genuinely interested in the opportunity.

2. Practice Common Interview Questions

Prepare for commonly asked interview questions related to your skills, experience, and qualifications. Practice answering these questions out loud to improve your fluency and confidence. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses effectively.

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact on previous roles. Use specific examples to illustrate your proficiency in operating and maintaining tablet making machines, conducting quality control checks, and troubleshooting.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show your passion for the industry and your eagerness to contribute to the company’s success. Dress professionally and arrive on time for your interview, as punctuality and a polished appearance reflect well on your character.

Next Step:

Now that you’re armed with the knowledge of Tablet Making Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tablet Making Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini