Feeling lost in a sea of interview questions? Landed that dream interview for Tabulating Machine Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tabulating Machine Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

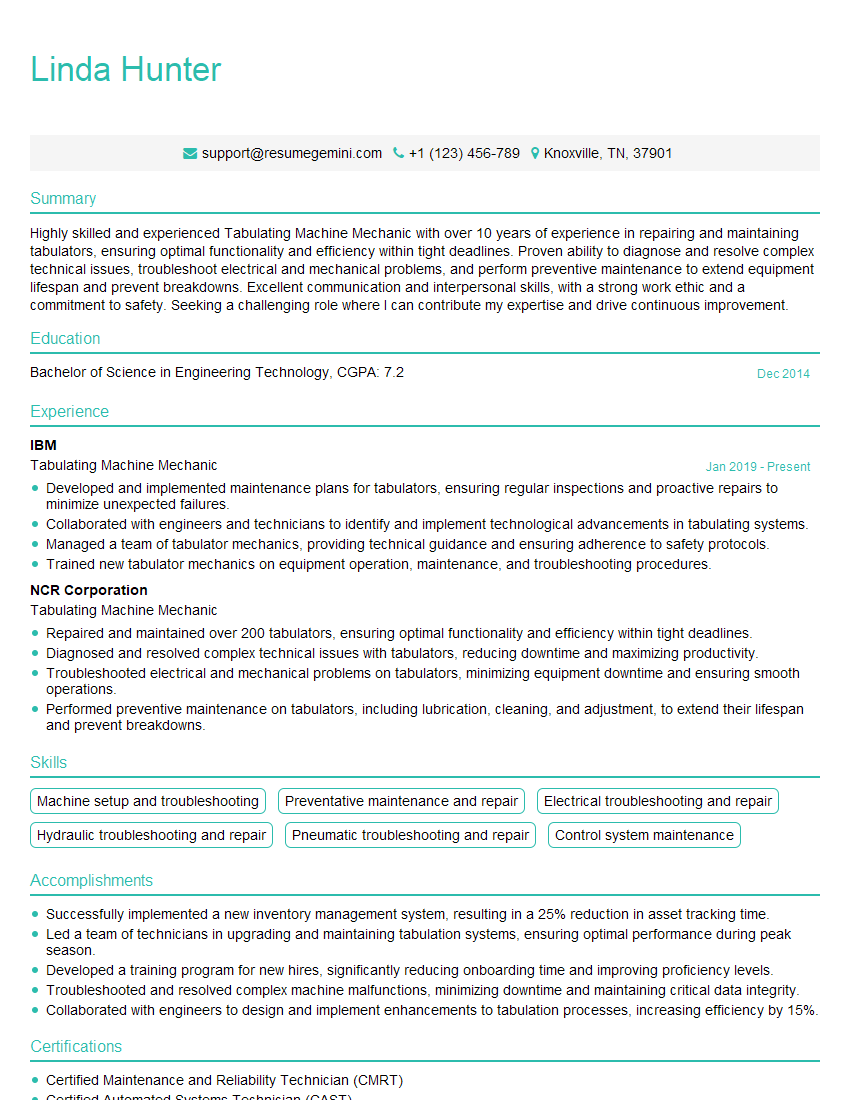

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tabulating Machine Mechanic

1. Describe the key responsibilities of a Tabulating Machine Mechanic.

As a Tabulating Machine Mechanic, my key responsibilities include:

- Performing scheduled maintenance and repairs on tabulating machines, ensuring optimal functionality.

- Diagnosing and troubleshooting machine malfunctions, identifying and resolving issues efficiently.

- Overhauling and rebuilding machines as necessary, ensuring extended lifespan and reliable performance.

- Collaborating with engineers and technicians to improve machine performance and develop innovative solutions.

- Adhering to safety regulations and industry best practices to maintain a safe work environment.

2. Explain the process of diagnosing a malfunctioning tabulating machine.

When diagnosing a malfunctioning tabulating machine, I typically follow these steps:

- Visual inspection: Examine the machine for any visible signs of damage or loose connections.

- Electrical testing: Use a multimeter to check electrical continuity and voltage levels.

- Mechanical inspection: Inspect gears, belts, and other mechanical components for wear or damage.

- Software diagnostics: Use diagnostic software to identify any software issues or error codes.

- Isolation and identification: Narrow down the potential causes by isolating the issue and identifying the specific component or system at fault.

3. How do you maintain and calibrate tabulating machines to ensure accuracy and efficiency?

To maintain and calibrate tabulating machines, I perform the following tasks:

- Regular cleaning and lubrication: Regularly clean and lubricate all machine components to prevent wear and tear.

- Mechanical adjustments: Make precise mechanical adjustments to ensure proper alignment and operation of components.

- Electrical calibration: Use calibration tools and software to verify and adjust electrical parameters.

- Accuracy testing: Conduct accuracy tests using standard test decks to ensure machines meet performance specifications.

- Documentation: Maintain detailed records of maintenance and calibration procedures for traceability and compliance.

4. Describe your experience in troubleshooting complex tabulating machine issues.

In my previous role, I encountered a complex issue where a tabulating machine was experiencing intermittent paper jams. I conducted a thorough diagnosis, including:

- Mechanical inspection: Verified that the paper path was clear and that all rollers were functioning properly.

- Electrical testing: Checked the voltage and continuity of the paper feed system.

- Software diagnostics: Analyzed error logs and identified a software glitch causing the jams.

- Resolution: Updated the machine’s firmware, which resolved the software issue and eliminated the paper jams.

5. How do you stay updated with the latest advancements in tabulating machine technology?

To stay updated with the latest advancements in tabulating machine technology, I regularly engage in the following activities:

- Industry conferences and workshops: Attend industry events to learn about new technologies and best practices.

- Technical publications and journals: Read technical publications and industry journals to stay informed about emerging trends.

- Manufacturer training: Participate in training programs offered by equipment manufacturers to gain in-depth knowledge of new machine features and technologies.

- Online forums and communities: Engage in online forums and communities to connect with other professionals and discuss technical advancements.

6. Describe your experience in working with different types of tabulating machines from various manufacturers.

Throughout my career, I have worked with a wide range of tabulating machines from different manufacturers. These include:

- IBM: Tabulating machines such as the IBM 402, 407, and 80-column sorters.

- NCR: Tabulating machines such as the NCR 315-100 and 5000 series.

- Remington Rand: Tabulating machines such as the UNIVAC 1004 and 1005.

- Other manufacturers: Experience with machines from Burroughs, Honeywell, and Addressograph-Multigraph.

7. How do you handle working under pressure and meeting tight deadlines?

In the demanding environment of a production facility, I have developed effective strategies to handle pressure and meet tight deadlines:

- Prioritize tasks: Identify the most critical tasks and allocate resources accordingly.

- Time management techniques: Utilize time management tools and techniques to optimize efficiency.

- Effective communication: Communicate clearly and regularly with colleagues and supervisors to ensure everyone is on the same page.

- Stress management: Employ stress management techniques such as deep breathing and positive self-talk to maintain composure under pressure.

8. Explain your knowledge of mechanical engineering principles and their application to tabulating machine maintenance.

My background in mechanical engineering provides a solid foundation for understanding and maintaining tabulating machines:

- Machine design: Knowledge of machine design principles enables me to analyze and identify potential mechanical issues.

- Mechanics of materials: Understanding the properties and behavior of materials helps me assess and repair mechanical components.

- Fluid power: Familiarity with fluid power systems, including hydraulics and pneumatics, is essential for maintaining machine actuators.

- Electrical controls: Knowledge of electrical controls and circuitry enables me to troubleshoot electrical issues.

9. How do you ensure the safety of yourself and others when working on tabulating machines?

Safety is paramount in my work. I adhere to the following safety practices:

- Lockout/tagout procedures: Follow strict lockout/tagout procedures before performing any maintenance work.

- Proper attire: Wear appropriate safety gear, including safety glasses, gloves, and protective clothing.

- Hazard assessment: Identify potential hazards and take necessary precautions before starting work.

- Regular inspections: Conduct regular safety inspections to ensure that equipment is in good working order.

- Training and awareness: Attend safety training programs and stay informed about safety regulations.

10. Describe your approach to continuous improvement and maintaining a high level of technical expertise.

I am committed to continuous improvement and maintaining a high level of technical expertise:

- Industry research: Stay informed about the latest developments in the field through industry research and publications.

- Technical training: Attend workshops and training programs to enhance my technical knowledge and skills.

- Problem-solving: Approach technical challenges with a problem-solving mindset and seek innovative solutions.

- Documentation and sharing: Document best practices and share knowledge with colleagues to improve the overall technical expertise of the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tabulating Machine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tabulating Machine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tabulating Machine Mechanics are skilled professionals responsible for the maintenance and repair of tabulating machines, essential for data processing tasks. Their roles encompass a wide range of tasks, including:

1. Preventative Maintenance

Inspecting and diagnosing potential issues with tabulating machines before they occur

- Performing regular maintenance checks, cleaning, lubrication, and minor adjustments

- Monitoring machine performance to identify any deviations or anomalies

2. Troubleshooting and Repair

Diagnosing and resolving hardware or software issues affecting tabulating machines

- Identifying and replacing faulty components, such as sensors, actuators, and wiring

- Updating machine software, drivers, and firmware to address bugs or enhance functionality

3. Installation and Setup

Installing and configuring new tabulating machines or upgrades to existing systems

- Setting up hardware and software components according to manufacturer specifications

- Testing and verifying machine functionality before deployment

4. Training and Support

Providing training and technical support to users of tabulating machines

- Instructing users on proper operation and maintenance procedures

- Troubleshooting and resolving user queries or issues encountered while using the machines

Interview Tips

To ace an interview for a Tabulating Machine Mechanic position, candidates should prepare thoroughly and demonstrate their relevant skills and experience. Here are some vital tips:

1. Research the Company and Position

Gather information about the company’s industry, size, and culture. Study the specific requirements of the Tabulating Machine Mechanic role, as outlined in the job description.

2. Highlight Relevant Experience and Skills

Emphasize your experience in maintaining, repairing, and troubleshooting tabulating machines or similar equipment. Quantify your accomplishments whenever possible using specific metrics or examples.

- Example: “In my previous role, I successfully reduced machine downtime by 20% through proactive maintenance and efficient troubleshooting.”

3. Demonstrate Troubleshooting Abilities

Interviewers will be keen to assess your ability to diagnose and resolve complex technical issues. Prepare examples of challenging troubleshooting experiences you have encountered and how you overcame them.

- Example: “Once, a tabulating machine experienced intermittent data errors. I meticulously checked all electrical connections, replaced a faulty sensor, and recalibrated the machine, successfully resolving the issue.”

4. Showcase Technical Proficiency

Highlight your familiarity with the latest tabulating machine technologies, software, and industry best practices. Consider obtaining relevant certifications to demonstrate your expertise.

5. Emphasize Attention to Detail and Precision

Tabulating Machine Mechanics must be meticulous and precise in their work. Emphasize your attention to detail and ability to work accurately in a fast-paced environment.

- Example: “I meticulously follow manufacturer specifications and quality control procedures to ensure the highest level of accuracy in my maintenance and repair tasks.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tabulating Machine Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!