Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tack Driller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tack Driller so you can tailor your answers to impress potential employers.

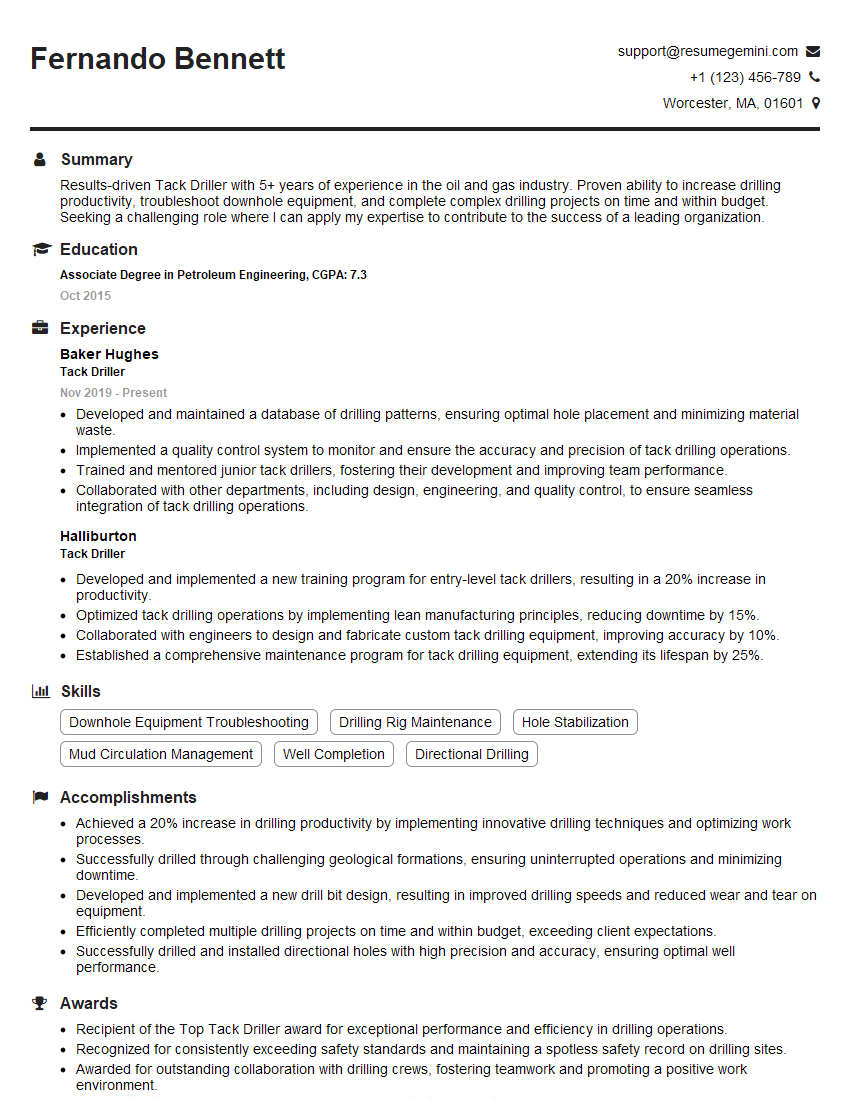

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tack Driller

1. What are the primary responsibilities of a Tack Driller?

As a Tack Driller, I would be responsible for:

- Operating and maintaining tack drilling equipment

- Drilling blast holes to specified depths and diameters

- Loading and unloading explosives, detonators, and other materials

- Connecting wires and detonators to ensure proper blasting

- Following safety protocols and regulations to prevent accidents

2. Describe the different types of tack drills you have experience with?

Rotary Tack Drills

- Pneumatic rotary tack drills

- Hydraulic rotary tack drills

Percussive Tack Drills

- Pneumatic percussive tack drills

- Hydraulic percussive tack drills

3. What are the key considerations for selecting the right drill bit and explosives for a given drilling task?

The selection of drill bit and explosives depends on several factors, including:

- Type of rock or soil being drilled

- Depth and diameter of the hole required

- Presence of water or other fluids

- Environmental and safety considerations

4. How do you ensure the safety of yourself and others while operating a tack drill?

- Wear appropriate personal protective equipment (PPE), such as hard hat, safety glasses, gloves, and earplugs

- Inspect the drill and equipment before use to ensure they are in good working order

- Follow established safety protocols for handling explosives

- Clear the area of personnel and obstacles before drilling

- Be aware of the surroundings and potential hazards

5. Describe the process of loading and blasting a tack hole?

- Drill the hole to the specified depth and diameter

- Clean the hole of debris

- Load the explosives and detonators into the hole

- Connect the wires and detonators according to the blasting plan

- Retreat to a safe distance and initiate the blast

6. How do you calculate the amount of explosives needed for a given drilling task?

To calculate the amount of explosives needed, I use the following formula:

- Explosive weight (kg) = (Hole volume (m³)) x (Explosive density (kg/m³)) x (Loading factor)

The loading factor varies depending on the rock type, hole diameter, and desired fragmentation.

7. What techniques do you use to minimize environmental impact during tack drilling?

- Use biodegradable or non-toxic materials whenever possible

- Control dust and noise pollution

- Properly dispose of waste materials

- Reclaim and rehabilitate drilling sites

8. How do you stay up-to-date on the latest techniques and technologies in tack drilling?

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Consult with manufacturers and experts in the field

9. Describe a challenging tack drilling project you have worked on and the solutions you implemented.

I worked on a project where the terrain was very rugged and difficult to access. To address this challenge, we used portable drilling equipment that could be easily transported and set up in remote areas. We also implemented a system of ropes and pulleys to transport materials to the drilling site.

10. Why are you interested in working as a Tack Driller with our company?

- I am attracted to the company’s commitment to safety and environmental responsibility

- I believe my skills and experience would be a valuable asset to your team

- I am eager to learn and grow in the field of tack drilling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tack Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tack Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tack Drillers, also known as Tack Welders, perform specialized welding tasks in various industrial and manufacturing settings. Their primary responsibility is to join metal pieces temporarily using tack welds, which are small, preliminary welds that hold pieces together until permanent welds can be applied.

1. Welding Operations

Tack Drillers use welding equipment and techniques to create tack welds. They interpret blueprints and welding procedures to accurately position and secure metal parts.

- Operate arc welding machines, such as gas metal arc welding (GMAW) and shielded metal arc welding (SMAW)

- Select and adjust welding parameters, including voltage, amperage, and polarity

- Position and hold welding torches or electrodes to create tack welds as per specifications

2. Equipment Maintenance

Tack Drillers are responsible for maintaining their own welding equipment to ensure proper operation and safety.

- Inspect and clean welding equipment, including torches, nozzles, and electrodes

- Troubleshoot and resolve minor equipment issues to minimize downtime

- Follow established safety protocols and wear appropriate protective gear

3. Quality Control

Tack Drillers visually inspect their welds to ensure they meet quality standards. They may also use non-destructive testing methods to verify weld integrity.

- Check weld size, shape, and penetration

- Identify and correct weld defects, such as undercuts, porosity, or cracking

- Maintain accurate records of welding activities for traceability and quality control purposes

4. Collaboration and Teamwork

Tack Drillers often work as part of a team alongside other welders, fabricators, and engineers.

- Collaborate with colleagues to ensure proper sequencing of welding tasks

- Follow instructions and communicate effectively with supervisors and team members

- Contribute to a safe and efficient work environment

Interview Tips

To ace an interview for a Tack Driller position, candidates should prepare thoroughly and demonstrate their skills and knowledge effectively.

1. Research the Company and Position

Before the interview, research the company’s background, industry, and specific requirements for the Tack Driller role. This will help you understand the company’s culture and align your answers with their expectations.

2. Highlight Relevant Experience and Skills

Showcase your welding skills and experience during the interview. Emphasize your proficiency in welding techniques, quality control procedures, and equipment maintenance. Highlight any relevant certifications or training you have obtained.

- Example Outline: “In my previous role, I was responsible for tack welding a wide range of metal components in a high-volume manufacturing environment. I consistently exceeded quality standards and maintained a high level of productivity.”

3. Demonstrate Safety Awareness

Safety is paramount in welding environments. Interviewers will assess your safety consciousness and adherence to safety protocols. Emphasize your understanding of welding safety regulations and your commitment to working safely.

- Example Outline: “I am highly safety-conscious and follow all established safety guidelines. I wear appropriate protective gear, inspect my equipment regularly, and maintain a clean and organized work area.”

4. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and availability. Practice answering these questions concisely and effectively, using specific examples to support your responses.

- Example Outline: “Can you describe your experience in troubleshooting welding equipment?”

5. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s welding practices, safety policies, or career advancement opportunities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tack Driller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tack Driller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.