Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tack Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

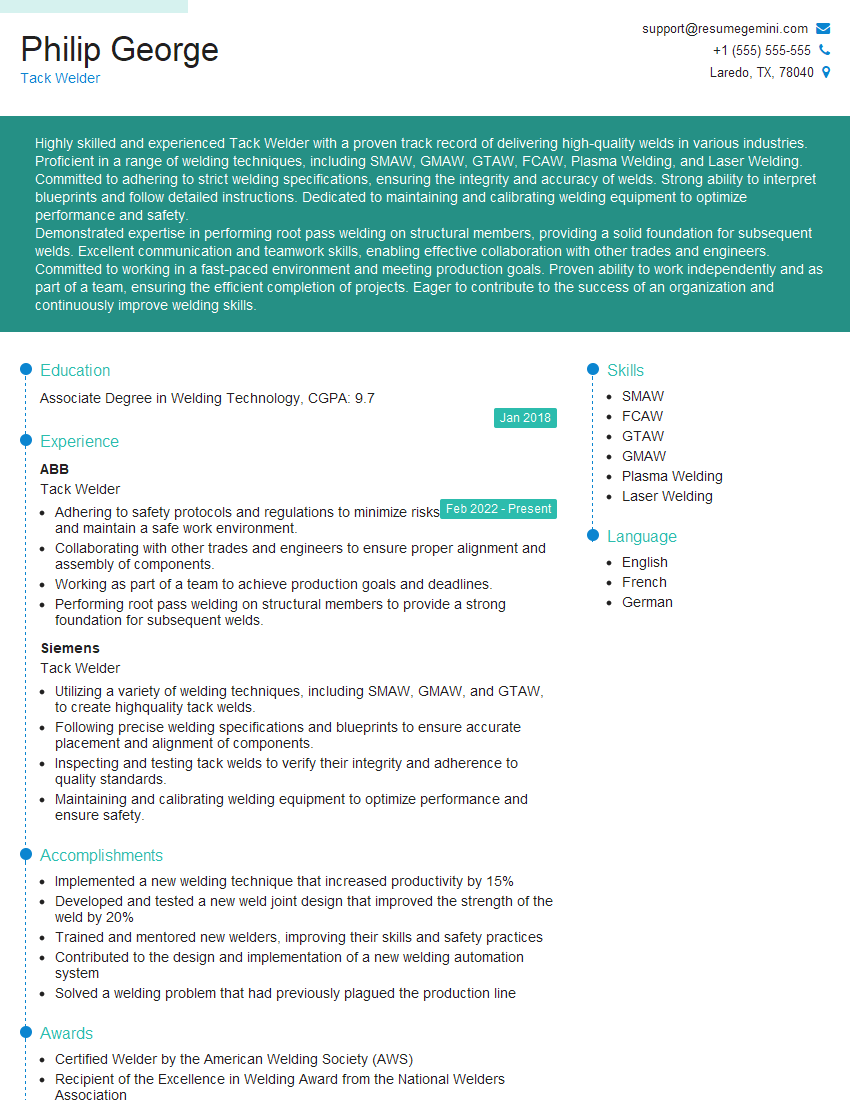

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tack Welder

1. How do you select the correct welding equipment for a specific welding task?

When selecting welding equipment, I consider the following factors:

- Type of metal: The type of metal being welded will determine the type of welding process and equipment required. For example, arc welding is typically used for welding ferrous metals such as steel and iron, while gas welding is often used for welding non-ferrous metals such as aluminum and copper.

- Thickness of the metal: The thickness of the metal will determine the amperage and power of the welding equipment required. Thicker metals require higher amperage and more powerful equipment.

- Welding position: The welding position (flat, vertical, overhead, etc.) will also affect the type of welding equipment required. Some welding equipment is designed for specific welding positions.

- Desired weld quality: The desired weld quality will also affect the type of welding equipment required. Some welding equipment is designed to produce higher quality welds than others.

- Portability: The portability of the equipment is important to consider, especially if you will be working in different locations.

2. What are the different types of welding joints?

Butt Joint

- The most common weld joint for joining two pieces of metal together.

- The edges of the metal are aligned and joined together.}

Edge Joint

- Used to join two pieces of metal that are perpendicular to each other.

- The edges of the metal are beveled and joined together.

T-Joint

- Used to join two pieces of metal that are perpendicular to each other.

- One piece of metal is at a 90-degree angle to the other.

Corner Joint

- Used to join two pieces of metal that are at a 90-degree angle to each other.

- The edges of the metal are joined together.

3. What are the common welding defects and how can you prevent them?

Incomplete fusion:

- A lack of fusion between the weld metal and the base metal.

- Prevention: Ensure proper joint preparation, use the correct welding parameters, and maintain a consistent welding speed.

Porosity:

- Small holes or cavities in the weld metal.

- Prevention: Use clean welding materials, protect the weld area from drafts, and use the correct shielding gas.

Undercut:

- A groove melted into the base metal adjacent to the weld.

- Prevention: Use the correct welding angle, travel speed, and amperage.

Overlapping:

- When the weld metal flows over the edges of the joint.

- Prevention: Use the correct welding technique and travel speed.

4. How do you test the quality of a weld?

- Visual inspection: The weld is visually inspected for any defects, such as cracks, porosity, or undercut.

- Destructive testing: The weld is tested by applying a load to it until it fails. This test can determine the strength of the weld.

- Non-destructive testing: The weld is tested using methods such as radiography, ultrasonic testing, or liquid penetrant testing. These tests can detect defects without damaging the weld.

5. What are the safety precautions that must be taken when welding?

- Wear proper protective clothing: This includes a welding helmet, gloves, and apron.

- Protect your eyes: Always wear a welding helmet with the proper shade of lens to protect your eyes from the intense light.

- Ventilate the work area: Welding fumes can be harmful, so it is important to ventilate the work area to remove them.

- Handle welding equipment safely: Welding equipment can be dangerous, so it is important to handle it safely and according to the manufacturer’s instructions.

6. What is your experience with different welding processes?

I have experience with the following welding processes:

- Arc welding: This is the most common type of welding process, and it uses an electric arc to melt the metal together.

- MIG welding: This is a type of arc welding that uses a consumable wire electrode.

- TIG welding: This is a type of arc welding that uses a non-consumable tungsten electrode.

- Gas welding: This is a welding process that uses a fuel gas and oxygen to create a flame that melts the metal together.

- Brazing: This is a metal-joining process that uses a filler metal with a lower melting point than the base metal. Brazing does not melt the base metal.

7. How do you stay up-to-date on the latest welding techniques and technologies?

I stay up-to-date on the latest welding techniques and technologies by:

- Attending welding conferences and trade shows: This is a great way to learn about new products and technologies.

- Reading welding magazines and journals: This is a good way to keep up with the latest trends in the welding industry.

- Taking welding courses: This is a great way to learn new skills and techniques.

- Networking with other welders: Talking to other welders is a great way to learn about new techniques and technologies.

8. What are some of the challenges you have faced as a tack welder, and how did you overcome them?

One of the challenges I have faced as a tack welder is working with different types of metals. Each type of metal has its own unique properties, so it is important to understand how to weld each type of metal properly. I have overcome this challenge by studying the different types of metals and practicing welding them.

Another challenge I have faced is working in different welding positions. Welding in different positions can be difficult, but it is important to be able to weld in all positions in order to be a versatile welder. I have overcome this challenge by practicing welding in different positions.

9. How do you ensure the accuracy and consistency of your tack welds?

I ensure the accuracy and consistency of my tack welds by using the following techniques:

- Properly preparing the joint: This includes cleaning the joint and making sure that the joint is properly aligned.

- Using the correct welding parameters: This includes using the correct amperage, voltage, and travel speed.

- Maintaining a consistent welding technique: This includes maintaining a consistent arc length and travel speed.

- Inspecting the welds: I inspect my welds to make sure that they are accurate and consistent.

10. What are your career goals as a tack welder?

My career goals as a tack welder are to:

- Become a certified welder: This will allow me to demonstrate my skills and knowledge to potential employers.

- Work on large-scale welding projects: I would like to work on projects that are challenging and that will allow me to use my skills to the fullest.

- Become a welding instructor: I would like to share my knowledge and experience with other welders and help them to develop their skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tack Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tack Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tack welders perform a critical role in ensuring the quality and durability of welded structures. Here are some key job responsibilities of a tack welder:

1. Preparation and Setup

Preparing the welding area, including cleaning and clamping workpieces

- Selecting and adjusting welding equipment

- Setting up fixtures and jigs

2. Tack Welding

Performing tack welds to hold workpieces together

- Determining the optimal tack weld locations and size

- Selecting the appropriate welding process and parameters

- Monitoring the tack weld quality and making adjustments as needed

3. Inspection and Finishing

Inspecting tack welds for defects

- Cleaning and finishing tack welds

- Preparing workpieces for final welding

4. Maintenance and Troubleshooting

Maintaining welding equipment

- Troubleshooting and resolving welding issues

- Ensuring a safe and efficient work environment

5. Quality Control

Adhering to quality standards and specifications

- Documenting tack welding procedures and results

- Participating in quality control inspections

Interview Tips

To ace an interview for a tack welder position, it is crucial to prepare thoroughly and highlight your skills and experience. Here are some tips:

1. Research the Company and Role

Learn about the company’s industry, products, and welding requirements

- Review the job description carefully to understand the specific responsibilities

- Practice answering common interview questions related to tack welding

2. Highlight Your Skills and Experience

Quantify your experience in tack welding

- Provide specific examples of welding projects you have completed

- Emphasize your proficiency in different welding processes and techniques

- Mention any industry certifications or training you have received

3. Demonstrate Safety Awareness

Welding is a potentially hazardous occupation

- Highlight your knowledge of welding safety protocols and regulations

- Provide examples of how you maintain a safe work environment

- Explain how you follow proper personal protective equipment (PPE) guidelines

4. Ask Meaningful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position

- Inquire about the company’s quality control standards

- Ask about opportunities for professional development

- Demonstrate your eagerness to learn and contribute to the team

5. Practice and Prepare

Practice your answers to common interview questions

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses

- Prepare questions to ask the interviewer

- Dress professionally and arrive on time for the interview

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tack Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.