Are you gearing up for a career in Tacking Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tacking Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

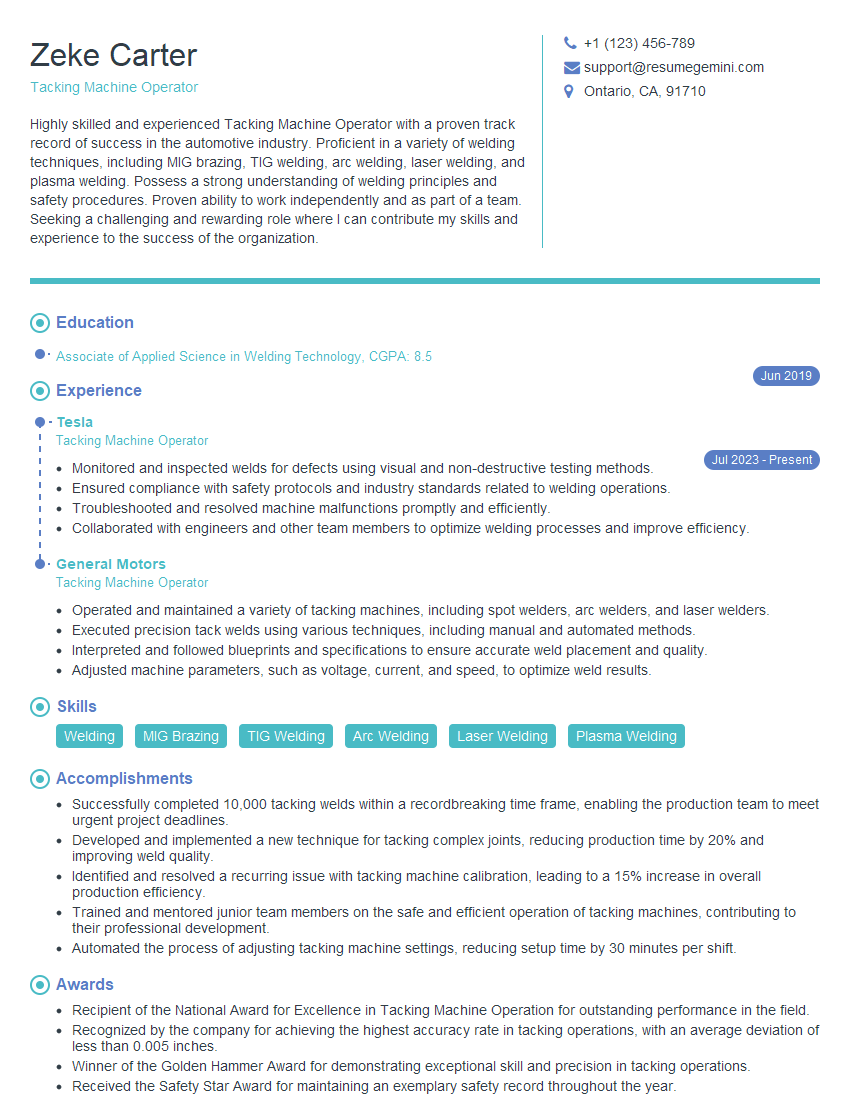

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tacking Machine Operator

1. Explain the different types of tacking machines used in garment construction?

- Portable tacking machines

- Stationary tacking machines

- Manual tacking machines

- Automatic tacking machines

2. What are the key operating principles of a tacking machine?

Electrical System

- Powers the machine and controls its functions.

- Includes a motor, circuit board, and wiring.

Mechanical System

- Responsible for the physical movement of the machine.

- Includes gears, levers, and other mechanical components.

Pneumatic System

- Uses compressed air to power certain functions.

- Provides force for tacking and other operations.

3. Describe the process of preparing and loading fabric onto a tacking machine?

- Inspect fabric for defects and remove any contaminants.

- Fold and align fabric according to specified measurements.

- Load fabric onto the machine’s work surface.

- Ensure that fabric is properly tensioned and aligned.

4. How do you set up and adjust a tacking machine for different types of fabrics?

- Select the appropriate needle size and thread type.

- Adjust the stitch length and tension settings.

- Test the machine on scrap fabric to ensure correct operation.

- Make necessary adjustments based on fabric type and desired results.

5. Explain the techniques involved in tacking different types of seams and edges?

- Plain Seams: Overlap fabric edges and stitch.

- Bound Seams: Fold and stitch fabric over a bias tape.

- French Seams: Enclose raw edges within the seam.

- Edges: Stitch around the edge of fabric to prevent fraying.

6. How do you maintain and troubleshoot a tacking machine?

Maintenance

- Regular cleaning and lubrication.

- Inspect needles and replace when necessary.

Troubleshooting

- Broken Needles: Check needle tension and type.

- Skipped Stitches: Adjust thread tension or replace needle.

- Puckering: Reduce stitch length or tension.

7. Describe the safety precautions that must be observed when operating a tacking machine?

- Wear appropriate safety gear (e.g., gloves, safety glasses).

- Keep hands and fingers away from moving parts.

- Never operate the machine with damaged or loose components.

- Unplug the machine before performing any maintenance or repairs.

8. How do you ensure the quality of tacked garments?

- Inspect garments for proper stitching and alignment.

- Check for any skipped stitches or loose threads.

- Ensure that the tacking is strong and secure.

- Follow established quality control procedures.

9. Explain how you would train a new operator on the operation and maintenance of a tacking machine?

- Provide hands-on instruction on machine operation.

- Explain safety precautions and maintenance procedures.

- Supervise and provide guidance during initial operation.

- Evaluate progress and offer ongoing support.

10. What strategies would you implement to increase productivity and efficiency on the tacking line?

- Optimize machine settings for different fabrics.

- Implement lean manufacturing principles to reduce waste.

- Provide continuous training to operators.

- Monitor and track production data to identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tacking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tacking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tacking Machine Operators play a crucial role in ensuring the accuracy and efficiency of assembly lines. Their primary responsibility is to operate and maintain automated tacking machines, which attach small pieces of metal together using adhesive.

1. Machine Operation and Maintenance

Operators are tasked with setting up, calibrating, and operating tacking machines. They must ensure that the machines are functioning properly and producing high-quality welds. Additionally, they are responsible for routine maintenance, troubleshooting, and minor repairs.

- Set up, calibrate, and operate automated tacking machines.

- Ensure accurate placement and adhesion of components.

- Perform routine maintenance and troubleshoot malfunctions.

2. Quality Control and Inspection

Tacking Machine Operators must inspect the finished products to ensure they meet specifications. They check for proper alignment, adhesion, and overall quality. Any defects or inconsistencies must be identified and addressed promptly.

- Inspect finished products for defects and errors.

- Identify and rectify non-conforming pieces.

- Maintain records of inspections and quality data.

3. Material Handling and Logistics

Operators are responsible for managing the flow of materials through the assembly line. They load and unload components, adjust material levels, and ensure the smooth operation of the entire process.

- Load and unload components into the tacking machine.

- Maintain optimal material levels for efficient production.

- Assist with logistics and material handling.

4. Safety and Compliance

Tacking Machine Operators must adhere to strict safety protocols and maintain a clean and organized work environment. They must be familiar with all relevant safety regulations and follow procedures to prevent accidents and injuries.

- Follow all safety protocols and regulations.

- Maintain a clean and organized work environment.

- Report any safety hazards or concerns.

Interview Tips

Preparing thoroughly for a Tacking Machine Operator interview is essential for success. Here are some valuable tips to help you impress the interviewer and land the job:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, values, and the expectations for the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Prepare specific questions about the company and position.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the Tacking Machine Operator position. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

- Describe your experience operating and maintaining tacking machines.

- Share examples of how you improved quality and efficiency.

- Highlight your ability to work effectively in a team environment.

3. Prepare for Common Interview Questions

Research common interview questions for Tacking Machine Operators and prepare thoughtful answers. Practice your responses in advance to build confidence and ensure clarity.

- Why are you interested in this position?

- Describe your experience with tacking machines.

- How do you handle pressure and deadlines?

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare a list of questions that demonstrate your knowledge of the industry and your enthusiasm for the position.

- What are the company’s plans for future growth?

- What is the company’s commitment to safety?

- How does the company support professional development?

5. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive for your interview on time. Punctuality shows respect for the interviewer and the company.

- Wear clean and pressed business attire.

- Arrive 10-15 minutes early for the interview.

- Maintain good posture and make eye contact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tacking Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!