Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tamping Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tamping Machine Operator so you can tailor your answers to impress potential employers.

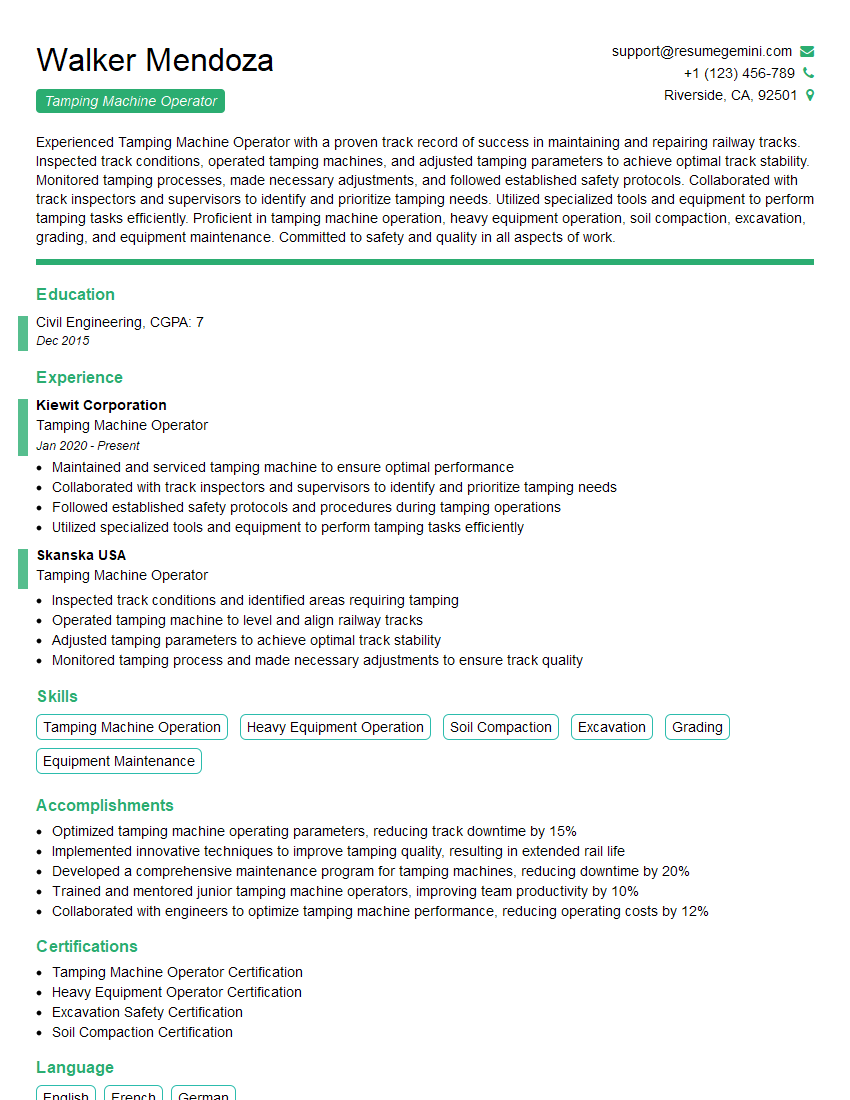

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tamping Machine Operator

1. Describe the process of tamping ballast under the track?

- The process of tamping ballast under the track involves using a tamping machine to compact the ballast and create a stable foundation for the track.

- The tamping machine moves along the track and uses a series of tamping tines to penetrate the ballast.

- The tamping tines vibrate and compact the ballast, creating a solid and stable foundation for the track.

- The tamping process helps to improve the track’s stability and prevent derailments.

2. What are the different types of tamping machines?

- There are two main types of tamping machines: continuous action tamping machines and shoulder tamping machines.

- Continuous action tamping machines tamp the ballast continuously as they move along the track.

- Shoulder tamping machines tamp the ballast at the shoulders of the track.

- Each type of tamping machine has its own advantages and disadvantages, and the type of machine used will depend on the specific track conditions.

3. What are the safety precautions that must be taken when operating a tamping machine?

- The operator must be trained and qualified to operate the tamping machine.

- The operator must wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- The operator must be aware of the surroundings and avoid any obstacles.

- The operator must follow all manufacturer’s instructions for operating the tamping machine.

- The operator must be aware of the potential hazards of operating the tamping machine, such as falling objects, moving parts, and electrical hazards.

4. What are the different types of ballast that can be used for tamping?

- The type of ballast used for tamping will depend on the specific track conditions.

- Common types of ballast include crushed stone, gravel, and slag.

- The ballast must be of a suitable size and shape to provide adequate drainage and support for the track.

5. What are the factors that affect the efficiency of tamping?

- The efficiency of tamping is affected by a number of factors, including the type of tamping machine, the type of ballast, the track conditions, and the operator’s skill.

- The operator can improve the efficiency of tamping by using the correct tamping techniques and by following the manufacturer’s instructions for operating the tamping machine.

6. What are the maintenance procedures that must be performed on a tamping machine?

- The operator must perform daily maintenance checks on the tamping machine, including checking the oil level, greasing the moving parts, and inspecting the tamping tines.

- The operator must also perform weekly and monthly maintenance checks, according to the manufacturer’s instructions.

- Regular maintenance is essential to keep the tamping machine in good working condition and to prevent breakdowns.

7. What are the troubleshooting procedures for a tamping machine?

- The operator must be able to troubleshoot common problems with the tamping machine.

- Common problems include engine problems, hydraulic problems, and electrical problems.

- The operator should follow the manufacturer’s instructions for troubleshooting the tamping machine.

8. What are the different types of tamping patterns that can be used?

- The operator can choose from a variety of tamping patterns to suit the specific track conditions.

- Common tamping patterns include single tamping, double tamping, and triple tamping.

- The operator should choose the tamping pattern that provides the best stability and support for the track.

9. What are the quality control procedures that must be followed when tamping?

- The operator must follow quality control procedures to ensure that the tamping is done to the correct standard.

- Quality control procedures include checking the ballast depth, the tamping pattern, and the track alignment.

- The operator should use a variety of tools to check the quality of the tamping, such as a ballast depth gauge, a tamping pattern gauge, and a track aligner.

10. What are the future trends in tamping technology?

- The future of tamping technology is likely to see the development of more automated and efficient tamping machines.

- New technologies, such as GPS and laser guidance systems, are being developed to improve the accuracy and efficiency of tamping.

- Tamping machines are also becoming more environmentally friendly, with the development of new technologies to reduce noise and emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tamping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tamping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tamping Machine Operators are responsible for operating, maintaining, and repairing tamping machines used in the construction and maintenance of railroads or highways. Their primary duties include the following:

1. Machine Operation and Control

Operate tamping machines to compact and level ballast under railroad ties or pavement materials on highways, ensuring stability and proper track alignment.

2. Equipment Maintenance and Repair

Conduct regular inspections and perform maintenance and repairs on tamping machines, including checking oil and hydraulic fluid levels, changing filters, and replacing worn parts.

3. Quality Control and Inspection

Monitor the tamping process to ensure it meets quality standards. Check track or pavement alignment, ballast density, and level to verify compliance with specifications.

4. Site Preparation and Clean-up

Prepare work sites by removing debris and installing track panels. Clean up work areas by removing excess ballast or pavement materials after tamping.

Interview Tips

To ace your interview for a Tamping Machine Operator position, consider the following tips:

1. Research the Company and Industry

Gather information about the company, its projects, and the specific role you are applying for. This demonstrates your interest and understanding of the company’s operations.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience operating and maintaining heavy machinery, specifically tamping machines or similar equipment. Showcase your knowledge of construction techniques and quality control procedures.

3. Prepare for Technical Questions

Expect questions about your understanding of tamping machine operation, maintenance, and quality control. Be prepared to discuss specific techniques and best practices you have employed.

4. Demonstrate Safety Consciousness

Stress your commitment to safety on the job. Tamping Machine Operators work in hazardous environments, so highlight your awareness of potential risks and your adherence to safety regulations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tamping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.