Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tank Builder Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tank Builder Supervisor so you can tailor your answers to impress potential employers.

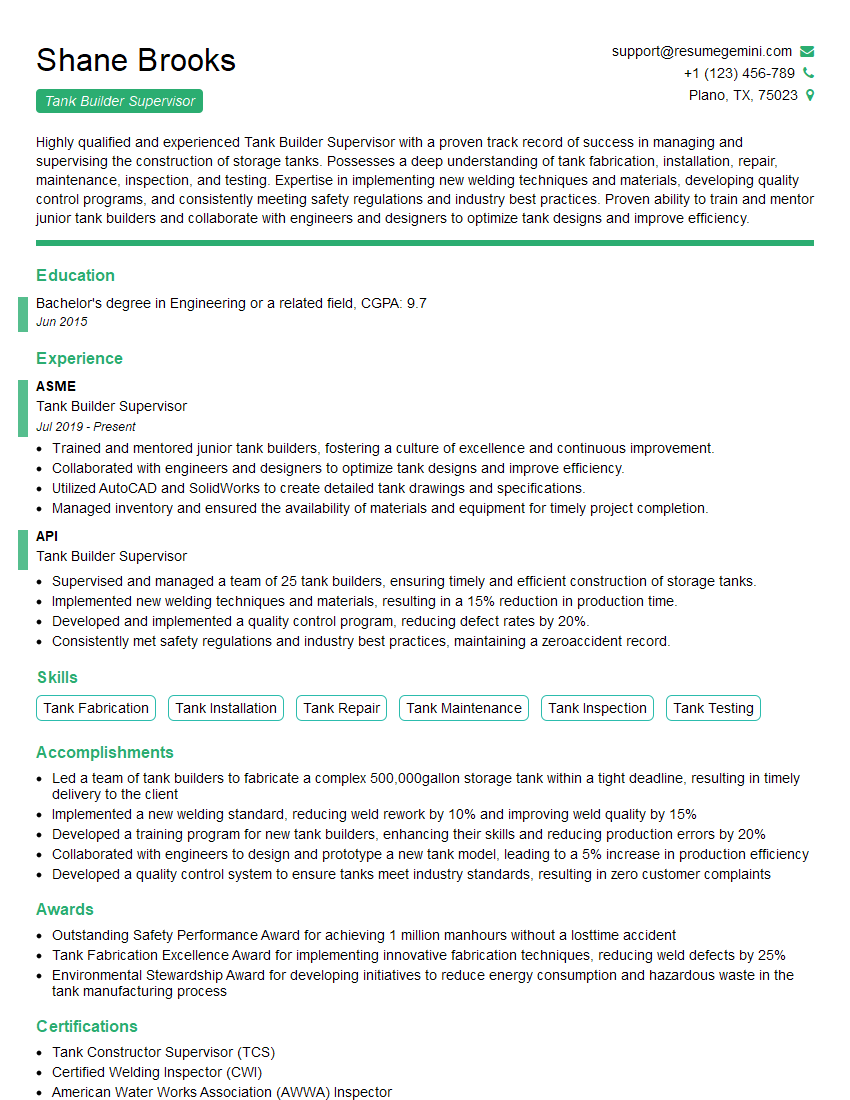

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tank Builder Supervisor

1. How do you ensure the quality of tank fabrication?

- Establish and follow quality control procedures to monitor each step of the fabrication process.

- Inspect raw materials, components, and finished products to verify conformity with design specifications and industry standards.

- Conduct non-destructive testing (NDT) to detect any defects or weaknesses in the tank structure.

- Review welding procedures, welder qualifications, and welding logs to ensure compliance with quality standards.

- Implement a system for tracking and resolving any non-conformances or deviations from the design or specifications.

2. Describe the different types of tanks you have experience in building.

Storage Tanks

- Vertical and horizontal storage tanks for liquids and gases.

- Above-ground and underground storage tanks.

- Double-walled tanks for hazardous materials.

Process Tanks

- Tanks used in chemical, pharmaceutical, and food processing industries.

- Tanks with agitators, heat exchangers, and other process equipment.

- Tanks made from materials such as stainless steel, carbon steel, and plastic.

Transportation Tanks

- Tanks for transporting liquids and gases by road, rail, or sea.

- Tanks designed to meet specific DOT and industry regulations.

- Tanks made from materials such as aluminum, steel, and fiber-reinforced plastics.

3. What is your experience in managing a team of tank builders?

- Provide clear instructions and set performance expectations for team members.

- Monitor progress, provide feedback, and address any issues or concerns promptly.

- Coordinate with other departments, such as engineering, procurement, and quality control, to ensure smooth project execution.

- Foster a positive and collaborative work environment, encouraging teamwork and professional development.

- Implement safety procedures and ensure compliance with all relevant regulations.

4. Describe a challenging tank fabrication project you have worked on and how you overcame the challenges.

- Technical challenges: Describe a project with complex design requirements, tight tolerances, or unusual materials.

- Team challenges: Highlight a project where you had to work closely with a diverse team or overcome communication barriers.

- Resource challenges: Discuss a project with limited resources or time constraints.

- How you overcame the challenges: Explain the strategies, techniques, and solutions you implemented to successfully complete the project.

- Lessons learned: Summarize what you learned from the experience and how it has improved your approach to tank fabrication.

5. What are the safety precautions you take when working with tanks?

- Confined space entry procedures for working inside tanks.

- Proper ventilation and respiratory protection to prevent exposure to hazardous fumes.

- Lockout/tagout procedures to prevent accidental startup or movement of equipment.

- Safe handling and storage of flammable and hazardous materials.

- Regular maintenance and inspection of equipment to ensure safe operation.

6. What are the latest trends in tank fabrication technology?

- Advanced welding techniques, such as robotic welding and laser welding.

- Computer-aided design (CAD) and finite element analysis (FEA) for tank design and stress analysis.

- Non-destructive testing (NDT) methods, such as ultrasonic testing and radiographic testing.

- Use of composite materials and fiber-reinforced plastics for lightweight and corrosion-resistant tanks.

- Automation and digitalization of tank fabrication processes, including remote monitoring and control.

7. How do you stay updated with the latest industry standards and regulations?

- Attend industry conferences and seminars.

- Review technical journals and publications.

- Participate in professional organizations, such as the American Welding Society (AWS).

- Collaborate with tank manufacturers, suppliers, and consultants.

- Stay informed about changes in building codes, safety regulations, and environmental standards.

8. What is your approach to managing project budgets?

- Establish a detailed budget and track expenses throughout the project.

- Identify potential cost-saving measures without compromising quality.

- Negotiate with suppliers and contractors to secure competitive pricing.

- Monitor project progress and make adjustments as needed to stay within budget.

- Communicate regularly with clients to keep them informed about project costs and any potential budget deviations.

9. How do you handle customer complaints or requests for modifications?

- Listen attentively to the customer’s concerns and try to understand their needs.

- Review the contract and specifications to determine if the request is valid.

- Work with the customer to find a mutually acceptable solution that meets their requirements and is within the scope of the project.

- Document the changes and communicate them to the team for implementation.

- Follow up with the customer to ensure that they are satisfied with the resolution.

10. What is your vision for the future of tank fabrication?

- Increased automation and digitalization for improved efficiency and quality.

- Adoption of new materials and advanced manufacturing techniques for innovative tank designs.

- Focus on sustainability and environmental friendliness, including the use of renewable energy and recycled materials.

- Collaboration between tank fabricators, designers, and end-users to create customized and optimized solutions.

- Continuous improvement and research to push the boundaries of tank fabrication technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tank Builder Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tank Builder Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Tank Builder Supervisor is responsible for overseeing the construction and maintenance of storage tanks and other related equipment. They work closely with engineers, contractors, and other team members to ensure that the work is completed safely, efficiently, and according to specifications.

1. Planning and Scheduling

The Tank Builder Supervisor is responsible for developing and implementing construction plans and schedules. They work with other team members to develop a timeline for the project and coordinate the activities of the construction crew.

- Develop and implement construction plans and schedules.

- Coordinate the activities of the construction crew.

- Monitor progress and make adjustments to the schedule as needed.

2. Safety

The Tank Builder Supervisor is responsible for ensuring that the construction site is safe for workers and the public. They implement safety protocols and train workers on safety procedures.

- Implement safety protocols.

- Train workers on safety procedures.

- Conduct safety inspections.

3. Quality Control

The Tank Builder Supervisor is responsible for ensuring that the construction work meets the required standards of quality. They inspect the work of the construction crew and make sure that it is up to specifications.

- Inspect the work of the construction crew.

- Make sure that the work is up to specifications.

- Identify and correct any defects.

4. Customer Service

The Tank Builder Supervisor may be responsible for interacting with customers and providing them with updates on the progress of the project. They may also be called upon to resolve any issues that arise during construction.

- Interact with customers and provide them with updates on the progress of the project.

- Resolve any issues that arise during construction.

Interview Tips

Preparing for an interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you understand their culture, values, and what they’re looking for in a Tank Builder Supervisor. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website.

- Read the company’s social media pages.

- Check out the company’s Glassdoor page.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions before you go to your interview so that you can deliver your answers confidently and concisely.

- Practice answering common interview questions.

- Be confident and concise in your answers.

3. Prepare Questions for the Interviewer

Asking the interviewer questions shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include “What are the company’s goals for this position?” and “What are the biggest challenges facing the company right now?”

- Prepare questions for the interviewer.

- Show that you’re interested in the position and the company.

- Learn more about the company and the role.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also arrive on time for your interview and be prepared to shake the interviewer’s hand firmly.

- Dress professionally.

- Arrive on time for your interview.

- Shake the interviewer’s hand firmly.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tank Builder Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tank Builder Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.