Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tank Processor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

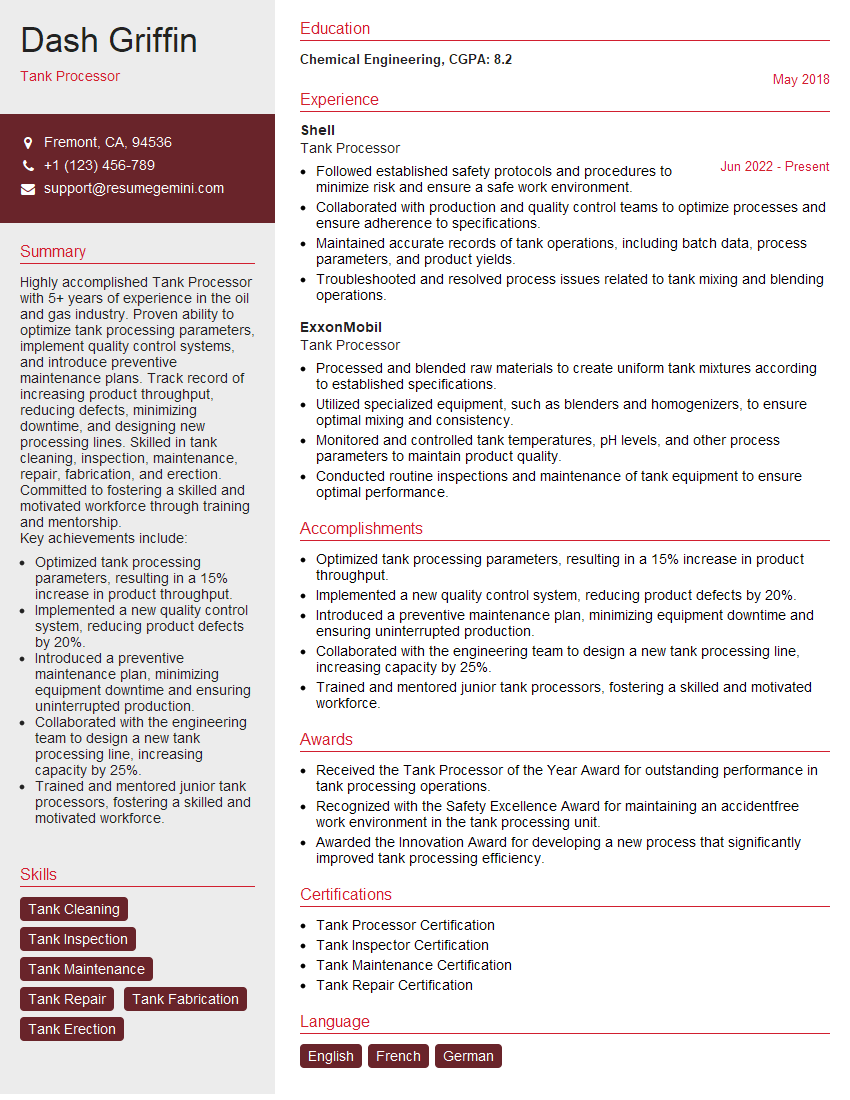

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tank Processor

1. What are the key responsibilities of a Tank Processor?

- Operate and maintain tanks and associated equipment used in the processing of chemical or petroleum products

- Monitor and control process variables such as temperature, pressure, flow rate, and level

- Troubleshoot and resolve operational issues

- Follow safety procedures and regulations

- Maintain a clean and organized work area

2. What are the different types of tanks used in chemical processing?

- Storage tanks: These tanks are used to store raw materials, intermediate products, and finished products.

- Reaction tanks: These tanks are used to carry out chemical reactions.

- Mixing tanks: These tanks are used to mix different ingredients together.

- Crystallization tanks: These tanks are used to crystallize products.

- Distillation tanks: These tanks are used to distill products.

3. What are the safety hazards associated with working with chemical tanks?

- Chemical spills: Chemical spills can occur if tanks are not properly sealed or if there is a leak in the piping.

- Fires: Fires can occur if flammable chemicals are not properly stored or if there is a spark or flame near the tank.

- Explosions: Explosions can occur if tanks are overfilled or if there is a build-up of pressure inside the tank.

- Toxic fumes: Toxic fumes can be released if chemicals are not properly ventilated.

- Skin and eye irritation: Chemicals can cause skin and eye irritation if they come into contact with the skin or eyes.

4. What are the different types of maintenance that are performed on tanks?

- Preventive maintenance: Preventive maintenance is performed on a regular basis to prevent problems from occurring.

- Corrective maintenance: Corrective maintenance is performed to fix problems that have already occurred.

- Emergency maintenance: Emergency maintenance is performed to fix problems that pose an immediate safety hazard.

5. What are the different types of instrumentation used to monitor and control tanks?

- Temperature sensors: Temperature sensors are used to measure the temperature of the contents of the tank.

- Pressure sensors: Pressure sensors are used to measure the pressure inside the tank.

- Flow meters: Flow meters are used to measure the flow rate of the contents of the tank.

- Level sensors: Level sensors are used to measure the level of the contents of the tank.

- Controllers: Controllers are used to control the temperature, pressure, flow rate, and level of the contents of the tank.

6. What are the different types of pumps used to transfer chemicals between tanks?

- Centrifugal pumps: Centrifugal pumps are the most common type of pump used to transfer chemicals between tanks.

- Positive displacement pumps: Positive displacement pumps are used to transfer chemicals that are viscous or contain solids.

- Air-operated diaphragm pumps: Air-operated diaphragm pumps are used to transfer chemicals that are corrosive or contain hazardous materials.

7. What are the different types of valves used to control the flow of chemicals between tanks?

- Gate valves: Gate valves are used to completely stop or start the flow of chemicals.

- Globe valves: Globe valves are used to regulate the flow of chemicals.

- Check valves: Check valves are used to prevent the backflow of chemicals.

- Ball valves: Ball valves are used to quickly stop or start the flow of chemicals.

- Butterfly valves: Butterfly valves are used to regulate the flow of chemicals.

8. What are the different types of piping used to connect tanks?

- Carbon steel piping: Carbon steel piping is the most common type of piping used to connect tanks.

- Stainless steel piping: Stainless steel piping is used to connect tanks that contain corrosive chemicals.

- PVC piping: PVC piping is used to connect tanks that contain non-corrosive chemicals.

9. What are the different types of gaskets used to seal connections between tanks and piping?

- Rubber gaskets: Rubber gaskets are the most common type of gasket used to seal connections between tanks and piping.

- Teflon gaskets: Teflon gaskets are used to seal connections between tanks and piping that contain corrosive chemicals.

- Graphite gaskets: Graphite gaskets are used to seal connections between tanks and piping that operate at high temperatures.

10. What are the different types of coatings used to protect tanks from corrosion?

- Epoxy coatings: Epoxy coatings are the most common type of coating used to protect tanks from corrosion.

- Polyurethane coatings: Polyurethane coatings are used to protect tanks from corrosion and abrasion.

- Fluoropolymer coatings: Fluoropolymer coatings are used to protect tanks from corrosion and high temperatures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tank Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tank Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

If you are interested in working in the refining of crude oil, then a job as a Tank Processor would be a great opportunity. Tank Processors play a vital role in the refining process, ensuring that the crude oil is processed correctly and safely. They are responsible for monitoring and controlling the flow of crude oil through the refinery, as well as for operating and maintaining the equipment used in the process.Here are some of the key job responsibilities of a Tank Processor:

1. Monitoring and controlling the flow of crude oil through the refinery

Tank Processors are responsible for ensuring that the crude oil flows through the refinery in a safe and efficient manner. They use a variety of equipment to monitor the flow of oil, including flow meters, pressure gauges, and temperature sensors. They also use computer systems to track the progress of the oil through the refinery.

- Use flow meters, pressure gauges, and temperature sensors to monitor the flow of oil.

- Use computer systems to track the progress of the oil through the refinery.

2. Operating and maintaining equipment used in the refining process

Tank Processors are responsible for operating and maintaining the equipment used in the refining process. This equipment includes pumps, compressors, tanks, and vessels. They also perform maintenance on the equipment, such as cleaning, lubricating, and repairing.

- Operate and maintain pumps, compressors, tanks, and vessels.

- Perform maintenance on equipment, such as cleaning, lubricating, and repairing.

3. Ensuring that the refining process is operating safely

Tank Processors are responsible for ensuring that the refining process is operating safely. They follow safety procedures and regulations, and they use their knowledge of the equipment and the process to identify and correct potential hazards.

- Follow safety procedures and regulations.

- Use knowledge of equipment and process to identify and correct potential hazards.

4. Communicating with other operators and supervisors

Tank Processors communicate with other operators and supervisors to coordinate the refining process. They also provide information on the status of the process to supervisors and managers.

- Communicate with other operators and supervisors to coordinate the refining process.

- Provide information on the status of the process to supervisors and managers.

Interview Tips

If you are preparing for an interview for a Tank Processor position, here are some tips to help you ace the interview:Here are some tips to help you ace the interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, in news articles, and on social media. You can also find information about the position in the job description.

- Visit the company’s website to learn about their culture and values.

- Read news articles and social media posts about the company to get a sense of their recent activities.

- Review the job description carefully to understand the specific requirements of the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses. You can practice answering these questions with a friend or family member, or you can record yourself answering the questions and then review your answers.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Practice answering these questions with a friend or family member.

- Record yourself answering the questions and then review your answers.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. Arriving late will show the interviewer that you are not organized or punctual.

- Dress professionally for your interview.

- Arrive on time for your interview.

4. Be confident and enthusiastic

Confidence and enthusiasm are important qualities for any job candidate. When you are confident and enthusiastic, you will come across as more passionate and interested in the position. You will also be more likely to impress the interviewer and make a good impression.

- Be confident and enthusiastic during your interview.

- Show the interviewer that you are passionate and interested in the position.

5. Ask questions

Asking questions at the end of the interview shows the interviewer that you are interested in the position and that you are taking the interview seriously. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

- Ask questions at the end of the interview.

- Show the interviewer that you are interested in the position and that you are taking the interview seriously.

- Learn more about the company and the position by asking questions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tank Processor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tank Processor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.