Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tank Pumper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

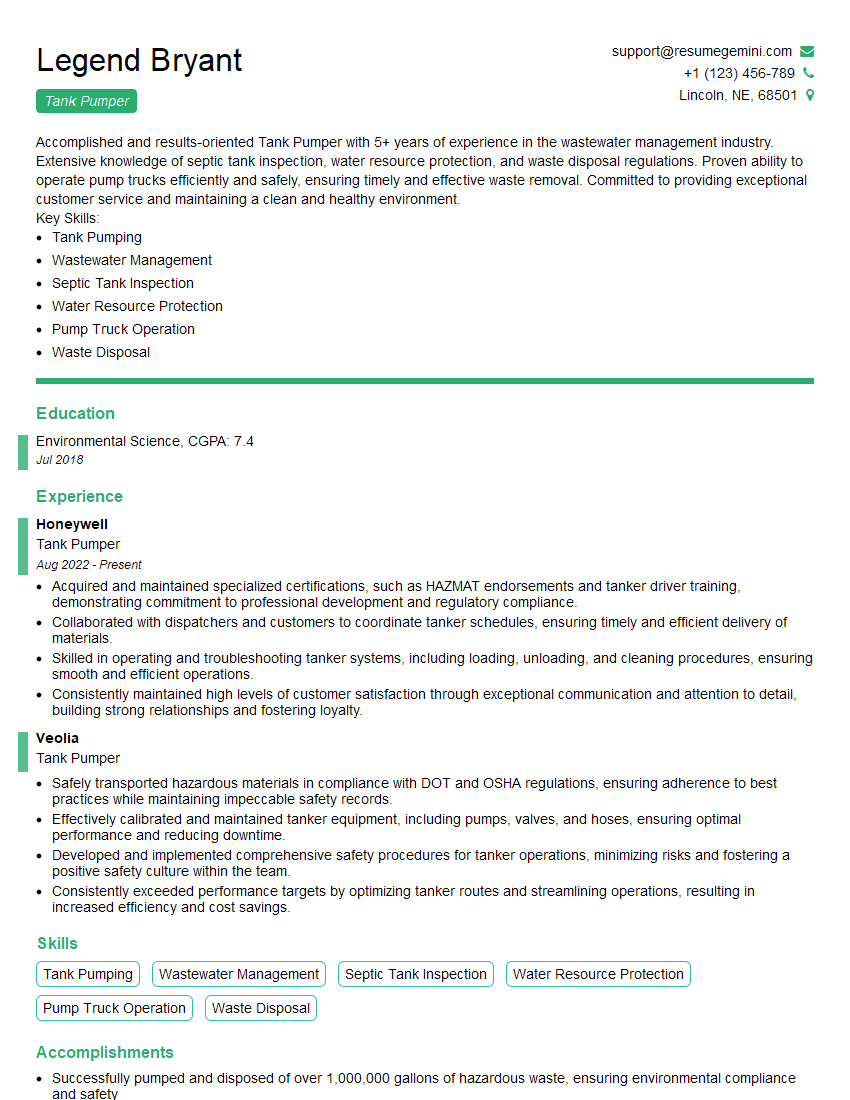

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tank Pumper

1. What actions should you take if you must stop pumping due to an emergency?

In the event of an emergency requiring a stop in pumping, the following steps should be taken:

- The tanker’s engine should be shut off.

- Disconnect the ground wire.

- Turn off all valves.

- Attempt to isolate the spill or leak using available materials.

- Contact emergency services and follow their instructions.

2. What types of tanker trucks are used to transport liquids?

Vacuum tanker

- Used to remove liquid waste from holding tanks.

- Employs a vacuum to suck up and transport the liquid.

Pressure tanker

- Used to transport liquids such as fuel or water.

- Employs a pump to pressurize and discharge the liquid.

3. How do you ensure the safety of the public when operating a tanker truck?

Ensuring public safety while operating a tanker truck requires adhering to the following measures:

- Obeying all traffic laws and speed limits.

- Maintaining a safe following distance.

- Being aware of surroundings and potential hazards.

- Wearing appropriate safety gear, such as gloves and a reflective vest.

- Communicating clearly with other drivers and pedestrians.

4. What are the different types of pumps used in tanker trucks?

- Centrifugal pumps: Used for high-volume, low-pressure applications.

- Positive displacement pumps: Used for low-volume, high-pressure applications.

- Reciprocating pumps: Used for precise and controlled pumping.

5. What are the key components of a tanker truck’s braking system?

- Air compressor: Supplies compressed air to the braking system.

- Air tanks: Store compressed air for use in braking.

- Brake valves: Control the flow of compressed air to the brakes.

- Brake chambers: Convert compressed air into mechanical force to apply the brakes.

- Brake shoes or pads: Create friction to stop the wheels.

6. What daily inspections are required for a tanker truck?

Daily inspections for a tanker truck include:

- Checking fluid levels (oil, coolant, brake fluid).

- Inspecting tires for wear and damage.

- Testing lights, signals, and brakes.

- Examining hoses and connections for leaks or damage.

- Verifying the operation of the pump and other equipment.

7. How do you handle hazardous materials when transporting them in a tanker truck?

Transporting hazardous materials requires strict adherence to the following guidelines:

- Wearing appropriate personal protective equipment (PPE).

- Following established routes and avoiding populated areas.

- Placarding the tanker truck with the appropriate hazard labels.

- Carrying emergency response information and spill containment materials.

- Coordinating with local authorities and emergency services in case of an incident.

8. What are the common causes of accidents involving tanker trucks?

- Driver fatigue: Long hours and demanding schedules can impair driver alertness.

- Speeding: Exceeding safe speed limits increases the risk of accidents.

- Improper loading or unloading: Improperly secured loads can shift and cause rollovers.

- Mechanical failures: Faulty brakes, steering systems, or tires can lead to accidents.

- Inclement weather: Rain, snow, and fog can reduce visibility and make driving hazardous.

9. What are the best practices for loading and unloading tanker trucks?

To ensure safe and efficient loading and unloading:

- Park the tanker truck on a level surface.

- Secure the tanker truck using wheel chocks.

- Ground the tanker truck to prevent static electricity buildup.

- Follow proper procedures for connecting hoses and opening valves.

- Monitor the loading or unloading process to ensure there are no leaks or spills.

10. How do you maintain the cleanliness of a tanker truck?

Maintaining tanker truck cleanliness involves:

- Regularly washing the exterior to remove dirt and debris.

- Cleaning the interior of the tank after each use to prevent contamination.

- Inspecting and replacing gaskets, seals, and hoses to prevent leaks.

- Using appropriate cleaning agents and disinfectants to ensure thorough cleaning.

- Adhering to industry standards and regulations for tanker truck sanitation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tank Pumper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tank Pumper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tank Pumpers are responsible for safely and efficiently pumping liquid or semi-liquid materials from storage tanks to various destinations. Their duties include:

1. Tank Pumping Operations

Operate tank pumping equipment to transfer materials between tanks, trucks, or other containers.

- Monitor and adjust pump settings to optimize transfer rates.

- Ensure the integrity of tanks and pipelines during operations.

2. Equipment Maintenance

Inspect and maintain tank pumping equipment to ensure optimal performance.

- Perform routine maintenance tasks such as cleaning, lubrication, and minor repairs.

- Report any issues or malfunctions to supervisors promptly.

3. Safety and Compliance

Follow all safety regulations and procedures to minimize risks.

- Wear appropriate safety gear and adhere to lockout/tagout procedures.

- Comply with environmental regulations related to material handling and disposal.

4. Recordkeeping and Reporting

Maintain accurate records of tank pumping operations and equipment inspections.

- Document transfer quantities, dates, and materials handled.

- Provide regular reports to supervisors on operations and maintenance activities.

Interview Tips

To ace your Tank Pumper interview, follow these tips:

1. Research the Company and Industry

Understand the company’s operations, products, and position within the industry. Research the specific requirements of the role you’re applying for.

2. Highlight Relevant Skills and Experience

Emphasize your experience in tank pumping operations, equipment maintenance, and safety procedures. Quantify your accomplishments whenever possible.

3. Prepare for Technical Questions

Expect questions about the principles of tank pumping, equipment specifications, and industry best practices. Be prepared to demonstrate your knowledge and expertise.

4. Show Safety Awareness

Safety is paramount in tank pumping. Emphasize your commitment to following safety protocols and regulations. Discuss specific examples of how you have ensured safety in previous roles.

5. Practice Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

6. Dress Professionally

First impressions matter. Dress appropriately for the interview, typically business casual attire.

7. Be Punctual

Arrive on time for your interview. Punctuality demonstrates respect for the interviewer’s time.

8. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions about the company, the role, or the industry. This shows engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tank Pumper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!