Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tank Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tank Worker so you can tailor your answers to impress potential employers.

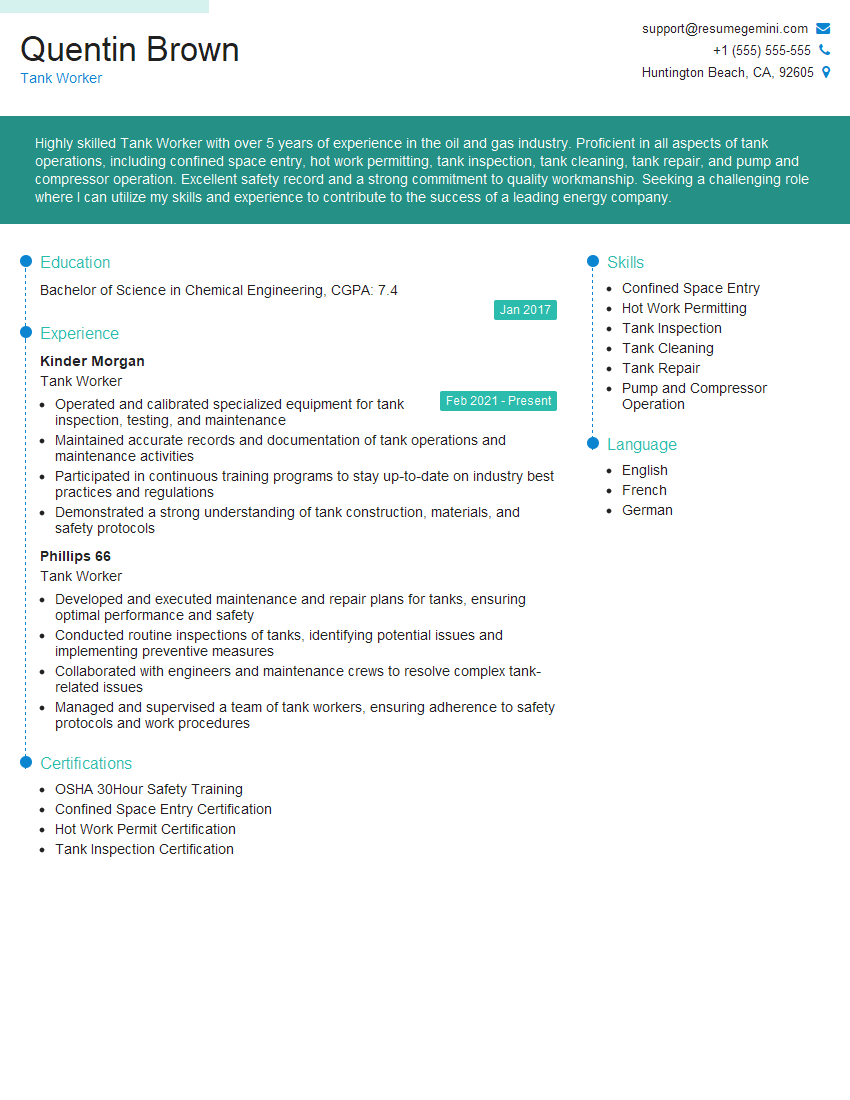

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tank Worker

1. What are the different types of tanks you have worked with?

In my previous role as a Tank Worker, I have experience working with a variety of tank types, including:

- Above-ground storage tanks (ASTs)

- Underground storage tanks (USTs)

- Pressure vessels

- Cryogenic tanks

2. What are the key safety protocols you follow when working with tanks?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, such as chemical-resistant gloves, protective clothing, and respirators

- Ensure PPE is properly fitted and inspected before use

Hazard Identification and Risk Assessment

- Identify potential hazards associated with the tank and its contents

- Conduct a risk assessment to determine appropriate control measures

Emergency Procedures

- Be familiar with emergency procedures for leaks, spills, and fires

- Know the location of emergency equipment and evacuation routes

3. What are the different methods of tank inspection and how do you determine which method is most appropriate?

The choice of tank inspection method depends on factors such as tank type, size, and contents. Common methods include:

- Visual inspection: Involves examining the tank for signs of leaks, corrosion, or damage

- Ultrasonic testing: Uses sound waves to detect flaws in the tank’s material

- Radiographic testing: Uses X-rays or gamma rays to create an image of the tank’s interior

- Magnetic particle testing: Uses magnetic particles to detect surface cracks

4. What is the role of cathodic protection in tank maintenance?

Cathodic protection is a technique used to prevent corrosion in metal tanks by applying an electric current to the tank’s exterior. This current creates a protective layer of hydrogen gas on the tank’s surface, which prevents the metal from coming into contact with corrosive substances.

5. How do you handle a tank leak or spill?

In the event of a tank leak or spill, I would prioritize the following steps:

- Safety first: Ensure the area is safe and evacuate personnel if necessary

- Stop the leak: Identify the source of the leak and take steps to stop it, such as using a patch or plugging the hole

- Contain the spill: Use absorbent materials to contain the spill and prevent it from spreading

- Notify authorities: Report the leak or spill to the appropriate authorities, such as the fire department or environmental agency

- Clean up and remediation: Once the leak or spill is contained, clean up the affected area and dispose of contaminated materials properly

6. How do you maintain accurate records of tank inspections and maintenance?

I maintain accurate records of tank inspections and maintenance using a combination of:

- Digital records: Use a software program or cloud-based system to store inspection reports, maintenance logs, and other relevant documents

- Paper records: Keep physical copies of inspection reports and maintenance records for backup and easy access

- Regular reviews: Periodically review inspection and maintenance records to ensure accuracy and completeness

7. How do you stay up-to-date on industry regulations and best practices for tank maintenance?

I stay up-to-date on industry regulations and best practices by:

- Attending industry conferences and workshops

- Reading industry publications and technical journals

- Participating in online forums and discussion groups

- Consulting with experts in the field

8. What is your experience with tank repair and fabrication?

In my previous role, I was responsible for repairing and fabricating tanks of various sizes and materials. This included:

- Welding: Repairing cracks, holes, and other defects in tanks using welding techniques

- Fabrication: Constructing new tanks or components from scratch using materials such as steel, stainless steel, and aluminum

9. How do you ensure the quality of your tank repair and fabrication work?

I ensure the quality of my tank repair and fabrication work by:

- Following manufacturer’s specifications and industry standards

- Using high-quality materials and equipment

- Conducting thorough inspections before, during, and after the repair or fabrication process

- Obtaining feedback from customers and other stakeholders

10. What is your experience with tank testing and certification?

I have experience conducting various types of tank testing and certification, including:

- Pressure testing: Testing tanks to ensure they can withstand internal pressure without leaking

- Leak testing: Testing tanks for leaks using methods such as hydrostatic testing or vacuum testing

- Certification: Certifying tanks to meet specific standards or regulations, such as ASME codes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tank Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tank Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tank Workers are responsible for the safe and efficient operation of tanks and other vessels used to store and process liquids and gases. Their duties include:

1. Preparing Tanks

Tank Workers prepare tanks for use, checking their condition and ensuring that they are free of debris and contamination.

- Inspecting tanks for damage, leaks, or corrosion

- Cleaning and sanitizing tanks

- Installing and removing equipment

2. Operating Tanks

Tank Workers monitor and operate tanks, ensuring that they are functioning properly and that products are being stored and processed safely.

- Monitoring temperature, pressure, and flow rates

- Adjusting valves and controls to maintain optimal conditions

- Filling and emptying tanks

3. Maintaining Tanks

Tank Workers perform regular maintenance on tanks to ensure their longevity and reliability.

- Inspecting and repairing tanks

- Calibrating and testing equipment

- Keeping records of maintenance activities

4. Safety and Compliance

Tank Workers adhere to strict safety and compliance regulations to ensure the safety of themselves, their colleagues, and the environment.

- Following safety protocols

- Wearing appropriate protective gear

- Reporting any incidents or concerns

Interview Tips

To ace the interview for a Tank Worker position, candidates should prepare by researching the role, practicing their answers to common interview questions, and presenting themselves professionally.

1. Research the Role and Company

Candidates should thoroughly research the Tank Worker role, including its responsibilities, qualifications, and industry trends.

- Read job descriptions and industry articles

- Visit the company’s website and social media pages

- Network with professionals in the field

2. Practice Common Interview Questions

Candidates should practice answering common interview questions, such as:

- Tell me about your experience working with tanks.

- What are your strengths and weaknesses as a Tank Worker?

- How do you ensure safety in your work?

3. Prepare STAR Stories

The STAR method involves describing a Situation, Task, Action, and Result when answering interview questions.

- Use specific examples from your experience to demonstrate your skills.

- Quantify your accomplishments whenever possible.

4. Dress and Act Professionally

Candidates should dress professionally for the interview and arrive on time.

- Wear business attire

- Be polite and respectful to the interviewer

- Maintain eye contact and speak clearly

5. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the role and the company.

- Ask about the company’s culture and values

- Inquire about opportunities for growth and development

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tank Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!