Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tap and Die Maker Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

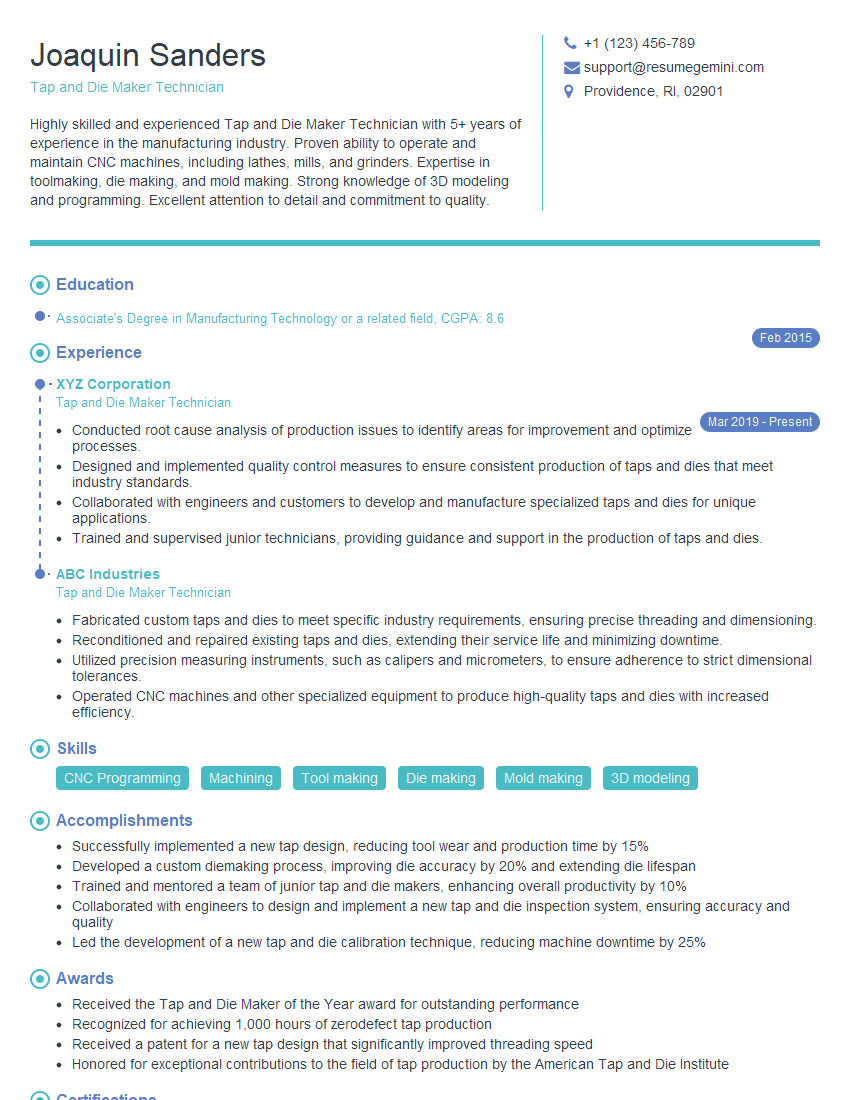

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tap and Die Maker Technician

1. What is the difference between a tap and a die?

- A tap is a cutting tool used to create internal threads in a workpiece.

- A die is a cutting tool used to create external threads on a workpiece.

2. What are the different types of taps?

Hand taps

- Used for creating threads by hand.

- Have a square shank that fits into a tap holder.

Machine taps

- Used for creating threads using a machine.

- Have a cylindrical shank that fits into a collet.

Form taps

- Used for creating threads with a specific profile.

- Have a formed cutting edge that matches the desired thread profile.

3. What are the different types of dies?

Hand dies

- Used for creating threads by hand.

- Have a split body that fits over the workpiece.

Machine dies

- Used for creating threads using a machine.

- Have a solid body that fits into a die holder.

Roll dies

- Used for creating threads by rolling the workpiece between two dies.

- Have a hardened surface that impresses the thread profile into the workpiece.

4. What are the different types of thread profiles?

ISO metric

- The most common thread profile used in metric countries.

- Has a 60-degree included angle and a rounded crest and root.

Unified National Coarse (UNC)

- A thread profile used in the United States and other English-speaking countries.

- Has a 60-degree included angle and a flat crest and root.

Unified National Fine (UNF)

- A thread profile used in the United States and other English-speaking countries.

- Has a 60-degree included angle and a smaller pitch than UNC.

5. What are the factors that affect the quality of a threaded joint?

The type of tap or die

The condition of the tap or die

The material of the workpiece

The cutting speed

The feed rate

6. What are the safety precautions that should be taken when using taps and dies?

Wear eye protection.

Use sharp taps and dies.

Use a lubricant when tapping or threading.

Secure the workpiece properly.

Do not over-tighten the tap or die.

7. How do you troubleshoot a threading problem?

- Check the tap or die for damage.

- Check the workpiece for defects.

- Adjust the cutting speed or feed rate.

- Use a different type of tap or die.

- Lubricate the tap or die.

8. What is the difference between a tap drill and a bottoming tap?

A tap drill

- Is used to create a hole that is the correct size for the tap.

- Has a pointed tip and a tapered shank.

A bottoming tap

- Is used to create a threaded hole that extends to the bottom of the hole.

- Has a flat tip and a straight shank.

9. What is the purpose of a chamfer on a tap?

A chamfer

- Is a bevelled edge at the end of a tap.

- Helps to start the tap in the workpiece and prevent the tap from breaking.

10. How do you calculate the cutting speed for a tap or die?

Cutting speed (feet per minute) = (number of teeth) * (pitch) * (RPM)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tap and Die Maker Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tap and Die Maker Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tap and Die Maker Technicians are responsible for the production and maintenance of taps and dies, which are tools used to cut threads in metal. They work in a variety of industries, including manufacturing, automotive, and aerospace.

1. Manufacture Taps and Dies

Tap and Die Maker Technicians use a variety of machines to manufacture taps and dies. These machines include lathes, milling machines, and grinders. They must be able to operate these machines safely and efficiently in order to produce high-quality products.

- Set up and operate machines to produce taps and dies

- Inspect taps and dies to ensure they meet specifications

- Sharpen and repair taps and dies

2. Maintain Taps and Dies

Tap and Die Maker Technicians are also responsible for maintaining taps and dies. This includes cleaning, lubricating, and replacing worn parts. They must be able to identify and troubleshoot problems with taps and dies in order to ensure they are operating properly.

- Clean and lubricate taps and dies

- Replace worn parts

- Troubleshoot problems with taps and dies

3. Quality Control

Tap and Die Maker Technicians must be able to ensure that the taps and dies they produce meet quality standards. They must be able to inspect taps and dies for defects and make sure they are within tolerance.

- Inspect taps and dies for defects

- Measure taps and dies to ensure they are within tolerance

- Maintain quality control records

4. Safety

Tap and Die Maker Technicians must follow all safety regulations in the workplace. They must wear appropriate safety gear and use machines safely. They must also be aware of the hazards associated with their work and take steps to avoid accidents.

- Follow all safety regulations

- Wear appropriate safety gear

- Be aware of the hazards associated with their work

Interview Tips

Preparing for an interview for a Tap and Die Maker Technician position can be stressful, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to understand the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Brainstorm a list of common interview questions

- Write out your answers to these questions

- Practice your answers out loud

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothes or revealing clothing

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive at your interview on time, or even a few minutes early.

- Plan your route to the interview in advance

- Leave yourself extra time in case of unexpected delays

- Call or email the interviewer if you are going to be late

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tap and Die Maker Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.