Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tap Puller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tap Puller so you can tailor your answers to impress potential employers.

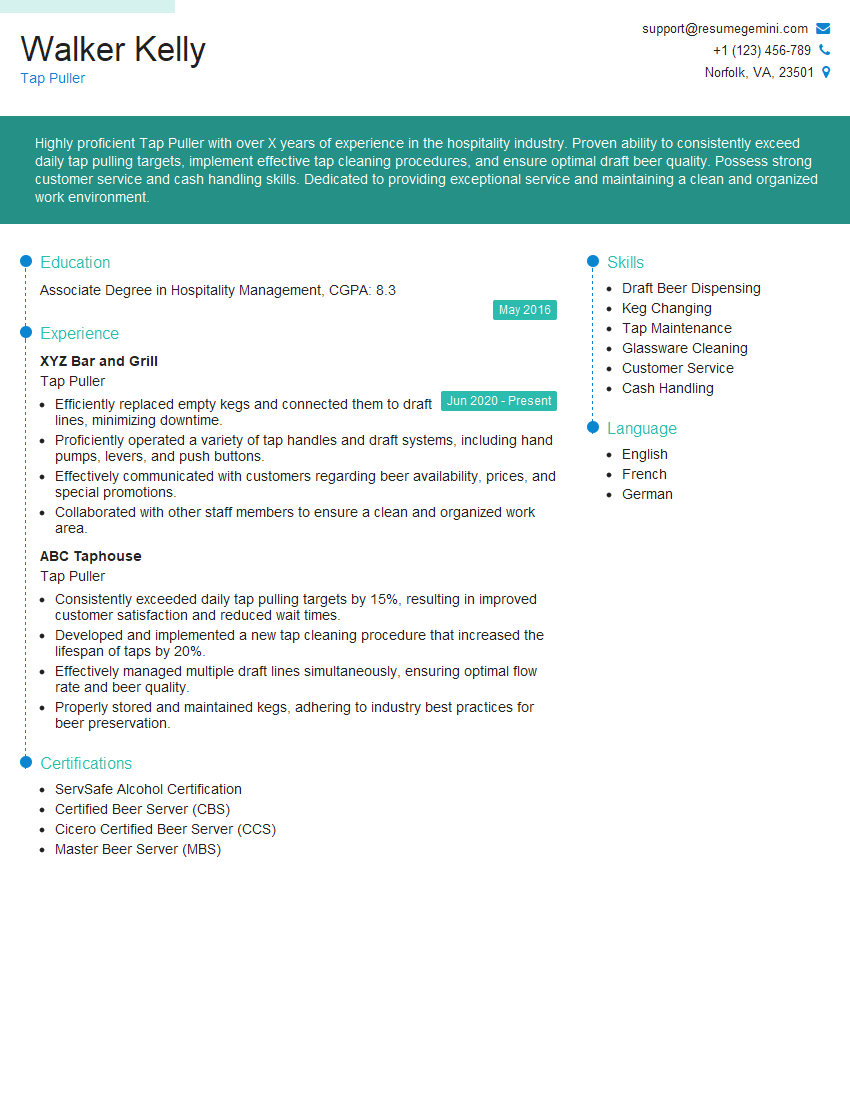

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tap Puller

1. Explain the process of removing a broken tap from a hole?

To remove a broken tap from a hole, I would:

- Assess the situation: Determine the size, location, and type of broken tap.

- Gather necessary tools: Collect appropriate tap extractors, drill bits, lubricants, and safety gear.

- Prepare the workpiece: Secure the workpiece and create a stable work environment.

- Drill a pilot hole: Carefully drill a small pilot hole into the center of the broken tap.

- Insert tap extractor: Select an appropriate tap extractor that matches the size and type of tap.

- Engage tap extractor: Insert the tap extractor into the pilot hole and engage it with the broken tap.

- Apply leverage: Use a wrench or other tool to apply force and slowly unscrew the broken tap.

- Lubricate: Apply lubricant regularly to reduce friction and prevent damage.

2. What are the different types of taps and their applications?

There are several types of taps with specific applications:

- Hand taps: Manually operated taps used for small-scale tapping operations.

- Machine taps: Designed for use in machines, offering higher precision and efficiency.

- Tapper taps: Used for tapping high-strength materials and creating coarse threads.

- Threading taps: Create threads in materials such as nuts and bolts.

- Chamfer taps: Used to bevel or chamfer the edges of holes before tapping.

Their applications include:

- Creating threads in metal workpieces

- Repairing damaged threads

- Producing precision threads in mass production

3. How do you determine the appropriate tap size for a given hole?

To determine the appropriate tap size, I consider the following factors:

- Screw size: The tap size must match the diameter of the screw or bolt to be used.

- Thread pitch: The tap pitch must match the pitch of the screw or bolt threads.

- Hole size: The tap size should be slightly smaller than the hole diameter to ensure a snug fit.

- Material hardness: Harder materials require smaller tap sizes to prevent overtapping and thread stripping.

I may consult tap charts or use standard formulas to calculate the correct tap size.

4. What are the safety precautions to observe when tapping?

- Wear appropriate PPE: Safety glasses, gloves, and earplugs.

- Secure workpiece: Ensure the workpiece is firmly clamped or held to prevent movement during tapping.

- Use sharp taps: Dull taps can cause the workpiece to grab and potentially injure the operator.

- Lubricate: Use cutting fluid or lubricant to reduce friction and prevent tap breakage.

- Control cutting force: Apply force gradually and avoid overtightening.

- Be aware of chips: Tapping creates chips, so wear eye protection and clear the work area regularly.

5. How do you maintain and troubleshoot tapping tools?

To maintain tapping tools, I perform the following tasks:

- Regular cleaning: Remove chips and debris from taps and extractors after each use.

- Sharpening: Use a tap sharpening tool to restore sharpness as needed.

- Lubrication: Apply oil or grease to taps and extractors to prevent rust and improve cutting performance.

- Storage: Store tools in a dry and protected environment.

Troubleshooting includes:

- Broken taps: Assess if the tap was overloaded, used improperly, or encountered a hard spot.

- Stripped threads: Determine if the tap was too large for the hole or if the material was too soft.

- Tapping difficulty: Check if the tap is dull, if the hole is out of alignment, or if the material is too hard.

6. What techniques can you use to improve tapping efficiency?

- Use sharp taps: Dull taps increase cutting force and reduce efficiency.

- Lubricate regularly: Lubrication reduces friction and improves tap life.

- Apply appropriate force: Excessive force can cause tap breakage, while insufficient force leads to thread stripping.

- Reverse tapping: Occasionally reversing the tapping direction can break up chips and improve thread quality.

- Use tapping fluids: Specialized fluids enhance cutting performance and increase tap life.

7. What are some common challenges in tapping and how do you overcome them?

- Hard materials: Use smaller tap sizes, reduce cutting force, and apply harder tap coatings.

- Oversized holes: Use undersized taps or tap inserts to create stronger threads.

- Thread galling: Apply anti-seize compounds or coatings to prevent threads from binding.

- Tap breakage: Ensure tap alignment, use sharp taps, and avoid overloading the tap.

- Stripped threads: Use thread inserts or re-tap the hole at a larger diameter.

8. What is the difference between a blind hole tap and a through-hole tap?

- Blind hole tap: Designed for tapping holes that do not extend through the workpiece.

- Through-hole tap: Used for tapping holes that extend completely through the workpiece.

Blind hole taps have a shorter flute length and a non-cutting tip to prevent bottoming out in the hole.

9. How do you measure and tolerance threads?

To measure and tolerance threads, I use the following methods:

- Thread gauges: Physical gauges that visually inspect thread size, pitch, and form.

- Thread micrometers: Precise instruments that measure thread diameter and pitch.

- Thread pitch gauges: Determine the thread pitch accurately.

Tolerance limits are established based on industry standards or specific requirements.

10. What are the different types of chip forms and how do they affect tapping performance?

- Continuous chips: Long, continuous chips indicate efficient tapping and optimal cutting parameters.

- Short chips: Short, broken chips result from harder materials or dull taps.

- Stringy chips: Long, curly chips occur due to excessive cutting force or improper lubrication.

- Broken chips: Fragmented chips can be caused by tap breakage or improper hole alignment.

Chip form analysis helps diagnose tapping issues and adjust parameters for improved performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tap Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tap Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tap Puller responsible for maintaining the quality and efficiency of the taps in a bar or restaurant. The primary focus of the role is to ensure that the taps are clean, properly calibrated, and dispensing the correct amount of beer. Additional responsibilities may include assisting with other tasks related to bar operations, such as restocking supplies or cleaning the bar area.

1. Tap Maintenance

Ensure that all taps are clean and in good condition to maintain sanitary standards and prevent contamination.

- Inspect taps regularly for leaks, blockages, or other issues.

- Clean taps according to established procedures to remove buildup and prevent bacteria.

2. Calibration and Adjustment

Calibrate and adjust taps to ensure they dispense the correct amount of beer, following legal requirements and customer expectations.

- Use specialized tools and techniques to calibrate taps to the proper flow rate.

- Adjust taps as needed to maintain optimal performance and prevent waste.

3. Keg Management

Manage beer kegs, ensuring a steady supply of fresh beer while minimizing waste and spoilage.

- Monitor keg levels and replace empty kegs with new ones.

- Properly store kegs in temperature-controlled areas to maintain beer quality.

4. Bar Assistance

Provide assistance with other bar operations as needed, ensuring smooth and efficient service.

- Restock supplies, such as glasses, napkins, and coasters.

- Clean and maintain the bar area, including tables, counters, and floors.

Interview Tips

Preparing for an interview for a Tap Puller position is essential to showcase your skills and qualifications. Here are some tips and hacks to help you ace the interview:

1. Research the Job

Familiarize yourself with the key job responsibilities and the specific requirements of the position. Visit the company’s website and read online reviews to gain insights into the company culture and expectations.

- Highlight your experience and skills that directly align with the job requirements.

- Example:

- Emphasize your experience in maintaining and calibrating taps, ensuring accurate beer dispensing.

- Explain your knowledge of beer kegs and best practices for storage and replacement.

2. Practice Your Answers

Take time to prepare answers to common interview questions related to your experience, skills, and motivations. Practice answering questions out loud to improve your delivery and confidence.

- Anticipate questions about your knowledge of beer styles, tap maintenance, and customer service.

- Example:

- Describe your understanding of different beer styles and how you ensure that they are dispensed at the correct temperature.

- Explain how you handle customer requests and resolve any issues related to tap performance.

3. Dress Professionally and Arrive Punctually

First impressions matter, so dress appropriately for the interview. Punctuality demonstrates respect for the interviewer’s time.

- A clean and pressed uniform or business casual attire is suitable for a Tap Puller interview.

- Allow ample time for transportation and arrive at the interview location on time to show your punctuality.

4. Be Enthusiastic and Show Your Passion

Convey your enthusiasm and passion for the hospitality industry and specifically for the role of a Tap Puller. Employers seek individuals who are genuinely interested in providing excellent customer service and ensuring the quality of beer.

- Share your knowledge of different beer styles and your interest in learning more about the industry.

- Example:

- Express your appreciation for the craft of beer making and your desire to contribute to the customer experience.

- Explain how you enjoy interacting with customers and providing them with a memorable experience.

5. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show your curiosity about the company, the position, or the industry.

- Questions about the bar’s beer selection, tap maintenance procedures, or the company’s commitment to customer satisfaction are appropriate.

- Example:

- Inquire about the bar’s plans for expanding its beer menu or introducing new beer styles.

- Ask about the company’s training programs for Tap Pullers and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tap Puller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!