Are you gearing up for an interview for a Tape Coater position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tape Coater and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

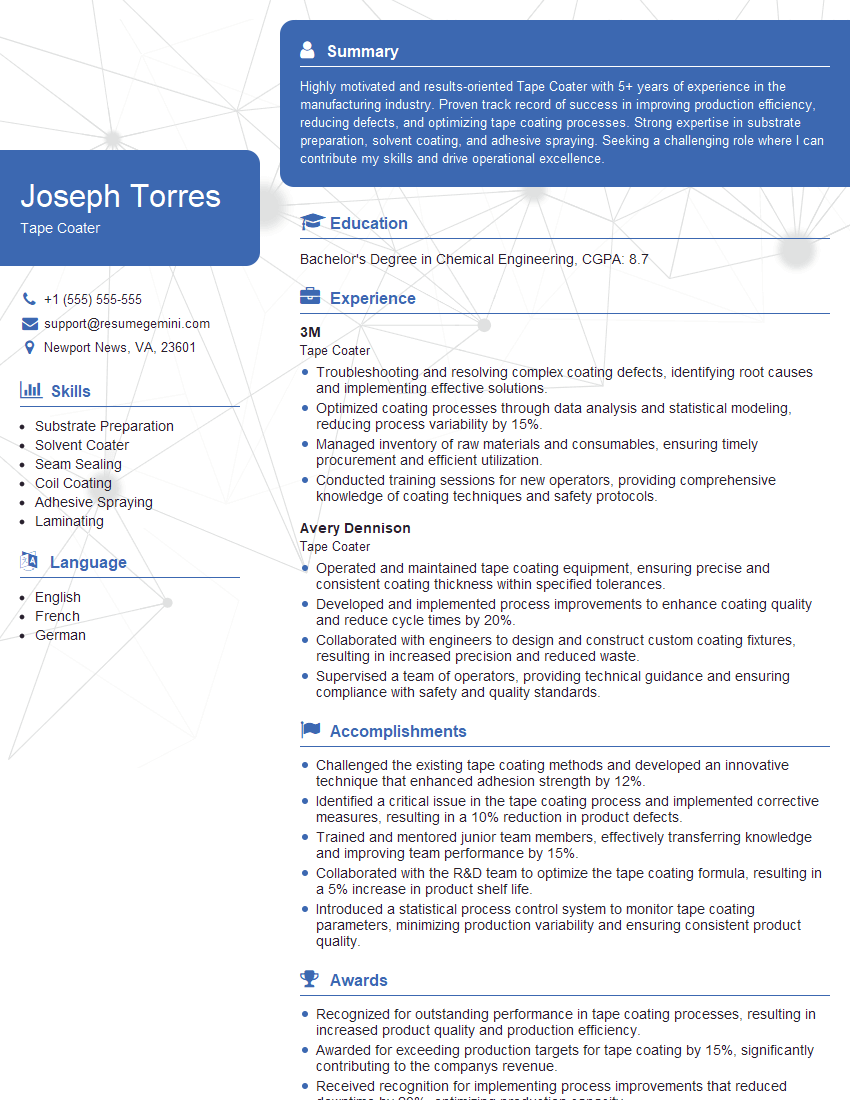

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tape Coater

1. Explain the process of tape coating.

Tape coating involves multiple steps:

- Substrate preparation: Selecting and cleaning the base material (e.g., polyester, metal foil) to ensure proper adhesion.

- Adhesive application: Applying a layer of adhesive onto the substrate using a coating head or roller.

- Tape unwinding and coating: Unwinding the backing material (e.g., paper, plastic) and passing it through the adhesive-coated substrate.

- Curing and drying: Exposing the coated tape to heat, UV light, or chemicals to activate the adhesive and strengthen the bond.

- Slitting and winding: Cutting the coated tape into desired widths and winding it onto reels.

2. What are the key factors that affect tape adhesion?

Substrate properties

- Surface roughness

- Chemical compatibility

- Energy (polarity)

Adhesive properties

- Tack and peel strength

- Shear strength

- Viscosity

Application factors

- Temperature and humidity

- Pressure and dwell time

- Surface preparation

3. Describe the different types of adhesives used in tape coating.

Adhesives commonly used in tape coating include:

- Acrylics: Versatile and general-purpose, with good adhesion to various surfaces.

- Silicones: Heat-resistant and moisture-proof, ideal for high-temperature and demanding applications.

- Rubber-based: High tack and peel strength, suitable for heavy-duty applications and bonding irregular surfaces.

- Hot melts: Thermoplastic adhesives that adhere upon cooling, offering high bond strength.

4. How do you determine the optimal adhesive thickness for a specific application?

Finding the optimal adhesive thickness involves considering several factors:

- Substrate and adhesive properties: Bond strength, surface energy, and compatibility.

- Application requirements: Load, stress, and environmental conditions.

- Coating method and equipment: Type of coating head, roller, or applicator.

- Testing and validation: Conducting peel, shear, or tensile tests to ensure adhesion performance meets specifications.

5. What are the common defects in tape coating and how do you identify and troubleshoot them?

Defects can arise during tape coating, including:

- Bubbles and voids: Entrapment of air during coating, causing weak adhesion.

- Wrinkles and folds: Improper tension control, leading to uneven coating and reduced bond strength.

- Delamination: Separation of adhesive from the substrate or backing.

- Contamination: Presence of foreign particles or oils, affecting adhesion.

Troubleshooting involves inspecting the coated tape, identifying the defect, and adjusting process parameters (e.g., adhesive thickness, tension, temperature) or equipment settings.

6. How do you maintain and calibrate the equipment used in tape coating?

Maintaining and calibrating equipment is crucial to ensure consistent tape quality.

- Coating head or roller: Regular cleaning and inspection for wear or damage.

- Tension controllers: Calibration using tension meters to ensure proper web tension.

- Ovens or curing systems: Temperature and humidity monitoring and adjustment for optimal curing conditions.

- Slitters and winders: Blade sharpness and alignment checks for precise cutting and winding.

7. Explain the quality control procedures for tape coating.

Quality control involves monitoring and testing to ensure tape meets specifications:

- Appearance inspection: Visual examination for defects, such as bubbles or wrinkles.

- Adhesion testing: Peel, shear, or tensile tests to measure bond strength.

- Environmental testing: Exposure to temperature, humidity, and chemicals to assess durability.

- Statistical sampling: Random sampling and testing to ensure consistency and process stability.

8. Discuss the safety precautions to be taken during tape coating operations.

Safety measures include:

- Proper ventilation: Adequate exhaust systems to remove fumes or solvents.

- Protective equipment: Gloves, respirators, and safety glasses to prevent contact with chemicals or debris.

- Machine guarding: Enclosures and interlocks to prevent access to moving parts.

- Electrical safety: Grounding, insulation, and lockout procedures to minimize electrical hazards.

9. Explain how you would optimize the tape coating process to improve efficiency and reduce waste.

Optimization strategies include:

- Process monitoring and data analysis: Using sensors and data loggers to identify bottlenecks and areas for improvement.

- Equipment upgrades: Investing in automated systems, high-precision coating heads, and efficient winders.

- Material choices: Selecting adhesives and substrates with optimal properties for the specific application.

- Training and operator skills: Providing training to ensure proper operation and maintenance.

10. Describe your experience in solving complex problems related to tape coating.

Explain a specific problem you encountered, how you diagnosed the issue, and the steps you took to resolve it.

- Problem statement: Clearly outline the challenge or issue faced.

- Diagnosis: Describe the process of identifying the root cause of the problem.

- Solution: Explain the specific actions taken to address the issue, including any equipment modifications, process adjustments, or material changes.

- Results: Quantify the improvements or benefits achieved by implementing the solution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tape Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tape Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tape Coaters are responsible for operating and maintaining tape coating machines, which apply a thin layer of material to a variety of surfaces. They work in a variety of industries, including manufacturing, packaging, and electronics.

1. Machine Operation

Tape Coaters are responsible for the safe and efficient operation of tape coating machines. They must be able to set up and adjust the machine, as well as monitor its operation to ensure that the tape is being coated correctly.

- Set up and adjust tape coating machines.

- Monitor the operation of tape coating machines to ensure that the tape is being coated correctly.

- Troubleshoot and repair tape coating machines.

2. Material Handling

Tape Coaters must be able to handle a variety of materials, including tape, adhesive, and solvents. They must be able to move materials safely and efficiently, and they must be able to follow instructions to ensure that the materials are used correctly.

- Handle a variety of materials, including tape, adhesive, and solvents.

- Move materials safely and efficiently.

- Follow instructions to ensure that the materials are used correctly.

3. Quality Control

Tape Coaters are responsible for ensuring that the tape is coated to the correct specifications. They must be able to inspect the tape for defects, and they must be able to make adjustments to the coating machine to ensure that the tape meets the required standards.

- Inspect the tape for defects.

- Make adjustments to the coating machine to ensure that the tape meets the required standards.

- Maintain records of the coating process.

4. Safety

Tape Coaters must be aware of the safety hazards associated with their work, and they must be able to follow safety procedures to protect themselves and others. They must be able to wear personal protective equipment, and they must be able to work in a safe and efficient manner.

- Be aware of the safety hazards associated with their work.

- Follow safety procedures to protect themselves and others.

- Wear personal protective equipment.

- Work in a safe and efficient manner.

Interview Tips

Preparing for an interview can be stressful, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Tape Coater position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website.

- Read the job description carefully.

- Look for news articles and social media posts about the company.

- Check out the company’s Glassdoor page.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, regardless of the position you are applying for. It is helpful to practice answering these questions in advance so that you can feel more confident during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your career goals?

- Why should we hire you?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. Avoid wearing clothing that is too revealing or too casual.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing clothing that is too revealing or too casual.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call the interviewer to let them know.

- Plan your route ahead of time.

- Leave early to give yourself plenty of time.

- If you are running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know who you are and what you are like, so don’t try to be someone you are not. Just be polite, respectful, and confident.

- Don’t try to be someone you are not.

- Be polite, respectful, and confident.

- Show the interviewer who you are and what you are like.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tape Coater role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.