Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tape Edge Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

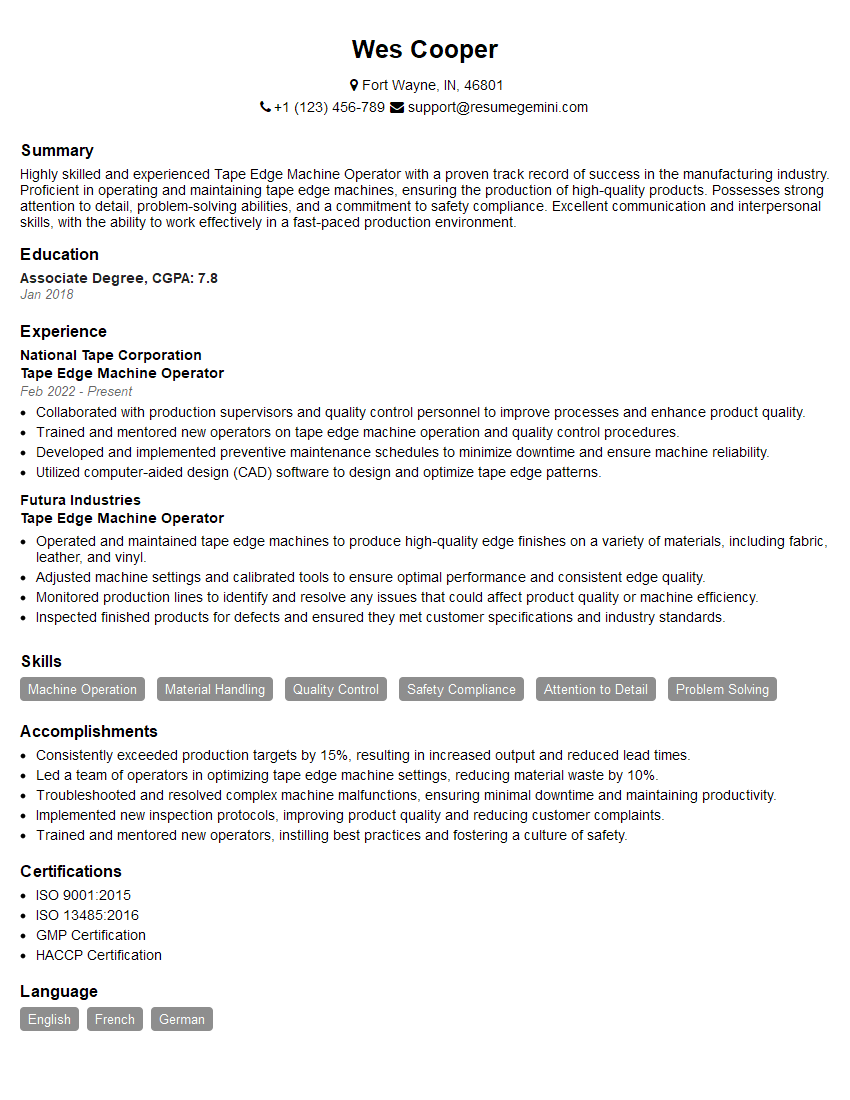

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tape Edge Machine Operator

1. Describe the key responsibilities of a Tape Edge Machine Operator?

As a Tape Edge Machine Operator, my key responsibilities encompass:

- Operating tape edge machines to apply adhesive tape to various materials, including fabrics, plastics, and metals

- Setting up and adjusting machines to ensure optimal tape application and alignment

- Monitoring machine operation and troubleshooting any issues that may arise

- Maintaining a clean and organized work area to ensure safety and efficiency

- Inspecting finished products for quality control and ensuring adherence to specifications

2. Explain the different types of tape edge machines and their applications?

Tape Edge Folding Machine

- Used to fold the edges of materials, such as fabrics, to create a clean and professional finish

- Applications include garment production, upholstery, and home décor

Tape Edge Sealing Machine

- Applies heat and pressure to seal tape edges, creating a strong and durable bond

- Used in packaging, automotive, and electronics industries to secure and protect products

Tape Edge Trimming Machine

- Trims excess tape from the edges of materials, ensuring a precise and clean finish

- Applications include label and sticker production, packaging, and graphic arts

3. How do you ensure the accurate alignment of tape during application?

To ensure accurate alignment, I employ the following techniques:

- Using alignment guides or laser markers on the machine

- Calibrating the machine regularly to maintain precision

- Manually adjusting the tape path as needed to compensate for variations in material thickness or shape

- Inspecting the alignment of the tape throughout the application process to identify and correct any deviations

4. Describe the safety precautions you observe when operating tape edge machines?

To maintain a safe work environment, I adhere to the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs

- Ensuring that the machine is properly grounded to prevent electrical hazards

- Keeping the work area clean and free of tripping hazards

- Being aware of moving parts and potential pinch points on the machine

- Following established lockout/tagout procedures when servicing or repairing the machine

5. How do you troubleshoot common problems that may occur during tape edge machine operation?

To effectively troubleshoot common problems, I follow these steps:

- Identifying the symptoms of the problem, such as uneven tape application, poor adhesion, or machine malfunctions

- Consulting the machine’s operating manual and maintenance guide for potential solutions

- Inspecting the machine for loose connections, damaged components, or incorrect settings

- Performing basic maintenance tasks, such as cleaning sensors or adjusting tension settings

- Contacting a qualified technician if the problem persists or requires specialized expertise

6. How do you maintain the quality of finished products produced by the tape edge machine?

To ensure the quality of finished products, I implement the following measures:

- Regularly inspecting raw materials, such as tape and substrates, for defects or inconsistencies

- Calibrating and maintaining the machine according to manufacturer’s specifications

- Monitoring the application process to identify any deviations from the desired settings

- Inspecting finished products visually and using quality control tools to assess adhesion, alignment, and overall appearance

- Documenting any quality issues and implementing corrective actions to prevent recurrence

7. How do you stay updated with the latest advancements in tape edge machine technology?

To keep abreast of technological advancements, I engage in the following activities:

- Attending industry conferences and workshops

- Reading trade publications and technical articles

- Exploring manufacturer websites and online resources

- Participating in online forums and discussion groups

- Consulting with suppliers and equipment experts

8. How do you handle working in a fast-paced production environment?

In a fast-paced production environment, I maintain efficiency and accuracy by:

- Prioritizing tasks and managing my time effectively

- Working independently and as part of a team to meet deadlines

- Communicating clearly with colleagues and supervisors

- Staying organized and keeping my work area tidy

- Taking breaks to maintain focus and prevent burnout

9. What motivates you to work as a Tape Edge Machine Operator?

I am motivated to work as a Tape Edge Machine Operator because I enjoy the precision and detail-oriented nature of the work.

- I find satisfaction in producing high-quality products that meet customer specifications

- The opportunity to troubleshoot problems and continuously improve my skills is also appealing to me

- Furthermore, I appreciate the importance of my role in supporting various industries and contributing to the overall success of the organization

10. Describe a situation where you successfully resolved a quality issue related to tape edge machine operation?

In my previous role, we encountered an issue where the tape was not adhering properly to the substrate.

- I investigated the problem by inspecting the raw materials, machine settings, and application process

- I discovered that the tape had been exposed to excessive moisture, which weakened the adhesive

- I implemented a solution by storing the tape in a controlled environment and using a pre-heating process to remove moisture before application

- This resolved the adhesion issue and improved the quality of the finished products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tape Edge Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tape Edge Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tape Edge Machine Operators play a crucial role in manufacturing operations by operating tape edge machines to join materials together. They ensure precise and efficient bonding of materials, which is essential for the production of various products.

1. Machine Operation

Operate tape edge machines to join different materials, such as fabrics, plastics, and leather.

- Load and position materials correctly on the machine.

- Adjust machine settings, including temperature, pressure, and speed.

2. Quality Control

Inspect and ensure the quality of the bonded materials.

- Identify and correct any defects or imperfections in the bonding process.

- Maintain high standards of accuracy and precision.

3. Maintenance and Troubleshooting

Perform routine maintenance on equipment to ensure optimal performance.

- Clean and lubricate machines.

- Troubleshoot and resolve machine malfunctions.

4. Production Optimization

Continuously monitor production processes.

- Identify areas for improvement in efficiency and productivity.

- Implement process enhancements to maximize output.

Interview Tips

Preparing for a Tape Edge Machine Operator interview requires careful consideration of the key responsibilities of the role and the specific qualifications sought by potential employers. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s products, services, and industry to demonstrate your interest and understanding of their business.

- Read the job description thoroughly and identify the required skills and experience.

- Prepare examples from your experience that showcase your abilities in these areas.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating tape edge machines and related equipment.

- Discuss your experience in setting up, adjusting, and troubleshooting machines.

- Provide specific examples of how you have improved production efficiency or quality through your technical expertise.

3. Demonstrate Quality Control Expertise

Showcase your ability to maintain high standards of quality in your work.

- Describe your inspection techniques and how you identify and resolve defects.

- Explain the importance of precision and accuracy in the role.

4. Emphasize Problem-Solving Abilities

Highlight your ability to troubleshoot and resolve machine malfunctions.

- Discuss your experience in diagnosing and repairing equipment issues.

- Provide examples of how you have used critical thinking and problem-solving skills to overcome challenges.

5. Showcase Attention to Detail

Emphasize your meticulous nature and focus on producing high-quality work.

- Explain how you ensure accuracy in loading and positioning materials on the machine.

- Provide examples of how you have identified and corrected minor imperfections in the bonding process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tape Edge Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tape Edge Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.