Feeling lost in a sea of interview questions? Landed that dream interview for Taper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Taper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

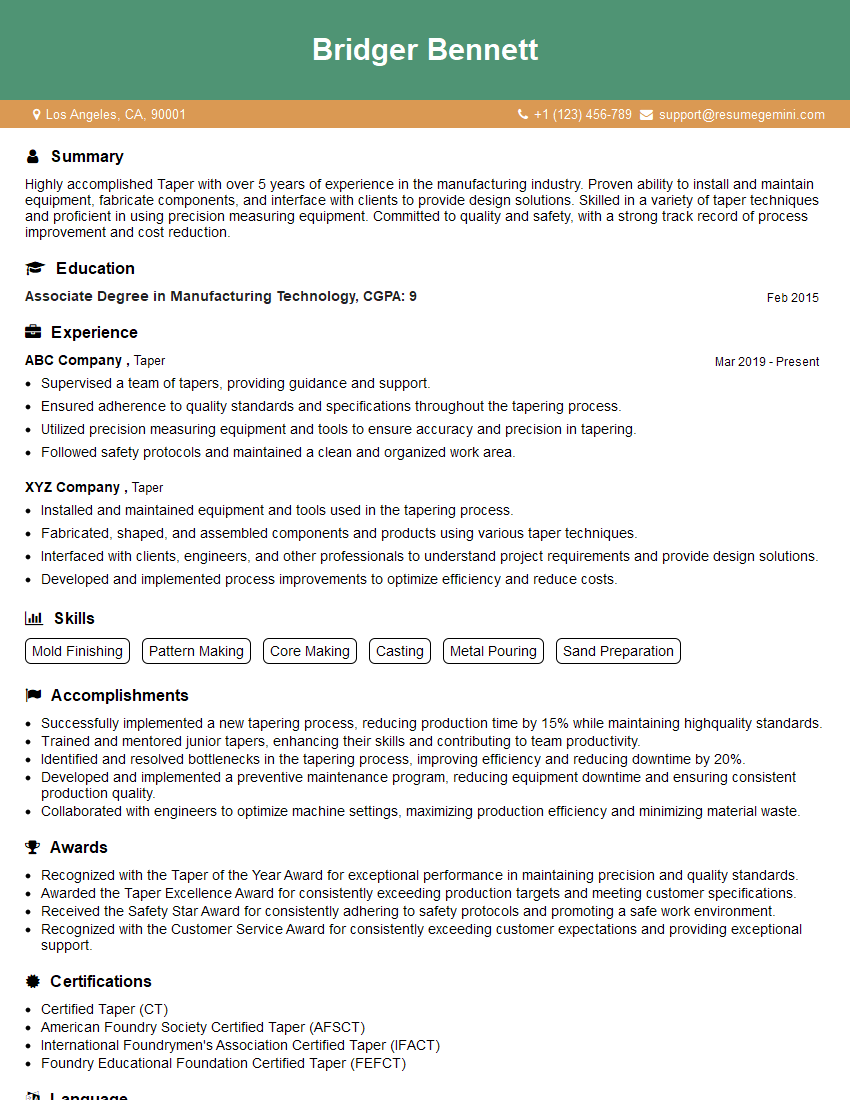

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Taper

1. What are the different types of taper sections used in the industry, and can you explain their advantages and disadvantages?

- Hex taper: Provides a strong and stable connection, but can be difficult to insert and remove.

- Conical taper: Easier to insert and remove than hex taper, but provides less stability.

- Morse taper: Self-centering and provides a secure connection, but can be difficult to remove if stuck.

- Jacobs taper: Most common taper type, provides a good balance of strength and ease of use.

2. How do you calculate the taper angle and taper ratio of a tapered hole?

Taper Angle Calculation:

- Taper Angle = arctan((DiameterDifference / 2) / HoleDepth)

Taper Ratio Calculation:

- Taper Ratio = DiameterDifference / HoleDepth

3. What are the different methods used to measure taper angle and taper ratio?

- Taper Gauge: Direct measurement of the taper angle.

- Coordinate Measuring Machine (CMM): High-precision measurement of both taper angle and ratio.

- Geometric Calculations: Using trigonometry and measurements of the taper.

4. How do you ensure the accuracy and precision of taper machining operations?

- Use sharp cutting tools: Sharp tools reduce chatter and improve surface finish.

- Control cutting parameters: Optimize feed rate, spindle speed, and depth of cut for the specific material.

- Set and maintain proper workholding: Secure the workpiece properly to prevent vibrations.

- Calibrate measuring instruments: Regularly calibrate taper gauges and CMMs to ensure accuracy.

5. What are the common materials used for taper machining, and how do you select the appropriate material for a specific application?

- Steel: Most common material, provides good strength and wear resistance.

- Stainless steel: Corrosion-resistant and suitable for acidic environments.

- Aluminum: Lightweight and machinable, but not as strong as steel.

- Titanium: Strong and lightweight, but more difficult to machine.

6. How do you troubleshoot common problems encountered during taper machining operations?

- Chatter: Caused by dull tools, excessive feed rates, or vibrations; use sharp tools and adjust parameters.

- Poor surface finish: Caused by blunt tools, improper cutting parameters, or workpiece movement; use sharp tools and optimize parameters.

- Taper angle deviation: Caused by incorrect machine setup, tool alignment, or workpiece distortion; verify setup and ensure proper clamping.

7. What are the latest advancements in taper machining technology?

- High-speed machining (HSM): Increased cutting speeds and feed rates.

- Advanced tool materials: Tools with improved hardness and wear resistance.

- CAM software: Enhanced simulation and verification of taper machining operations.

8. How do you stay updated with the latest trends and best practices in taper machining?

- Attend industry events and conferences: Network with experts and learn about new technologies.

- Read technical journals and articles: Stay informed about research and advancements.

- Complete online courses and certifications: Enhance knowledge and skills.

- Seek mentorship from experienced professionals: Learn from seasoned machinists.

9. What is your experience with programming and operating CNC taper machining centers?

- CNC knowledge: Familiarity with G-code programming and CNC operation.

- Taper machining experience: Successfully programmed and machined various tapers.

- Setup and troubleshooting: Experience in setting up and troubleshooting CNC taper machining centers.

10. How do you ensure the quality and accuracy of taper machined parts?

- Inspection plan: Establish a comprehensive inspection plan.

- Measurement equipment: Use calibrated measuring instruments (e.g., CMM, taper gauges).

- Statistical process control (SPC): Monitor and control machining processes.

- Continuous improvement: Regularly review and improve processes to enhance quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Taper is a skilled professional specializing in the finishing and texturing of drywall surfaces. They are responsible for preparing, applying, and smoothing drywall joint compound, creating a seamless and aesthetically pleasing surface for painting or other finishes.

1. Drywall Preparation

Preparing the drywall surface for taping involves removing debris, sanding rough edges, and applying primer to ensure a strong bond between the joint compound and the drywall.

- Clean and remove any dust, dirt, or debris from the drywall surface using a brush or vacuum cleaner.

- Sand rough edges or imperfections on the drywall using a drywall sander to create a smooth and even surface.

- Apply a coat of primer to the drywall surface to improve adhesion and prevent moisture absorption.

2. Joint Compound Application

Tapers apply joint compound to fill and conceal the joints between drywall panels, creating a smooth and seamless surface. This process requires precise application and proper technique to achieve a professional finish.

- Mix the joint compound according to the manufacturer’s instructions to achieve the desired consistency.

- Apply a thin layer of joint compound to the drywall joint using a taping knife, ensuring it is fully embedded and covering the joint tape.

- Smooth the joint compound using a taping knife, removing any excess and creating a flat, uniform surface.

3. Smoothing and Finishing

Once the joint compound has dried, tapers use various techniques to smooth and finish the surface, preparing it for painting or other finishes. This process requires attention to detail and skilled craftsmanship.

- Sand the dried joint compound using sandpaper or a sanding sponge to remove any rough edges or imperfections.

- Apply a second coat of joint compound to fill any remaining gaps or depressions, creating a smooth and even surface.

- Feather the edges of the joint compound to blend it seamlessly with the surrounding drywall surface.

4. Quality Control

Tapers play a crucial role in ensuring the quality of the finished drywall surface. They inspect their work regularly, identifying and correcting any defects or imperfections to meet the project specifications and industry standards.

- Inspect the finished drywall surface for any imperfections, such as cracks, holes, or unevenness.

- Repair any defects or imperfections promptly using appropriate techniques and materials.

- Ensure that the finished drywall surface meets project specifications and industry standards for quality.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and experience as a Taper. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific role you are applying for. Understand their business, values, and the industry they operate in. This knowledge will demonstrate your interest in the position and help you align your answers with the company’s needs.

- Visit the company’s website to learn about their history, mission, and services.

- Check industry news and articles to stay informed about the latest trends and developments in the drywall industry.

- Read online reviews and testimonials from former or current employees to gain insights into the company culture and work environment.

2. Highlight Your Skills and Experience

In the interview, emphasize your relevant skills and experience as a Taper. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

- Describe your experience in preparing, applying, and smoothing drywall joint compound.

- Showcase your proficiency in using various taping tools and techniques, such as taping knives, sanding sponges, and feathering tools.

- Mention any certifications or training you have completed to enhance your skills and knowledge in drywall finishing.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your qualifications. Practice answering these questions out loud to gain confidence and improve your delivery.

- Tell me about your experience as a Taper.

- Describe a challenging drywall project you worked on and how you overcame the obstacles.

- What are your strengths and weaknesses as a Taper?

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that demonstrate your curiosity about the company, the role, and the industry.

- What are the company’s goals and priorities for the upcoming year?

- How would you describe the ideal candidate for this Taper position?

- What opportunities are there for professional development and growth within the company?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Taper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.