Are you gearing up for a career in Taping Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Taping Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

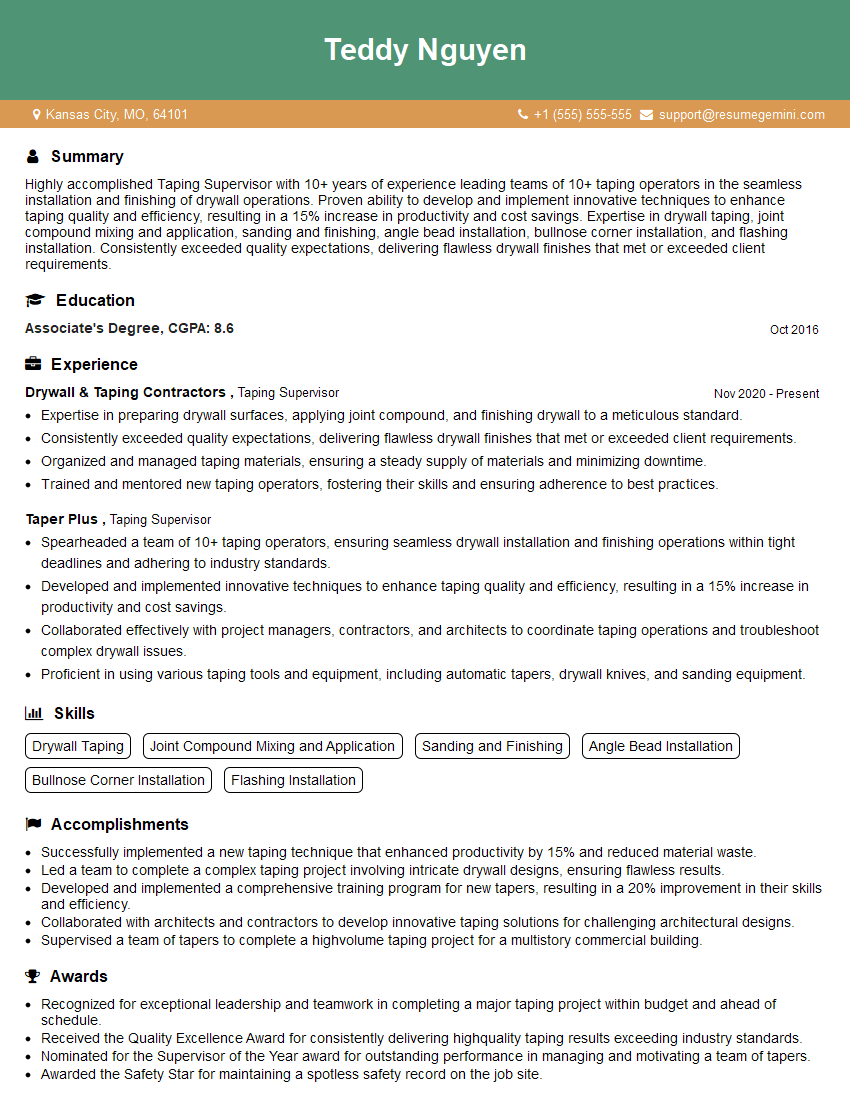

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Taping Supervisor

1. Explain the different types of taping machines and their applications?

There are three main types of taping machines:

- Manual taping machines are the most basic type and require the operator to manually feed the tape into the machine. These machines are typically used for small-scale taping operations.

- Semi-automatic taping machines use a motor to feed the tape into the machine. These machines are more efficient than manual taping machines and can be used for medium-scale taping operations.

- Fully-automatic taping machines are the most advanced type of taping machine and do not require any manual input from the operator. These machines are typically used for large-scale taping operations.

2. What are the key factors to consider when selecting a taping machine?

Factors to consider when selecting a taping machine:

- The type of tape you will be using

- The size and shape of the items you will be taping

- The speed and efficiency you require

- The budget you have available

3. How do you ensure that the taping process is efficient and accurate?

To ensure that the taping process is efficient and accurate, I would:

- Use the correct type of tape for the job

- Use the correct size and shape of tape for the items being taped

- Use the correct taping machine for the job

- Set up the taping machine correctly

- Train operators on how to use the taping machine correctly

- Inspect taped items regularly to ensure quality

4. What are the common problems that can occur during the taping process, and how do you troubleshoot them?

Common problems that can occur during the taping process include:

- The tape is not sticking properly

- The tape is tearing

- The tape is wrinkling

- The tape is not being applied evenly

Troubleshooting:

- Check the type of tape you are using

- Check the size and shape of the tape you are using

- Check the taping machine you are using

- Check the settings on the taping machine

- Check the training of the operators

- Inspect taped items regularly to ensure quality

5. What are the safety precautions that should be taken when operating a taping machine?

- Wear appropriate safety gear, such as gloves and safety glasses

- Keep hands and fingers away from moving parts

- Do not operate the machine if it is damaged

- Unplug the machine before making any repairs

- Follow all manufacturer’s instructions

6. What are the quality control measures that you would put in place to ensure that taped items meet customer requirements?

To ensure that taped items meet customer requirements, I would put in place the following quality control measures:

- Establish clear quality standards

- Train operators on how to meet quality standards

- Inspect taped items regularly to ensure quality

- Use statistical process control to monitor quality

- Take corrective action when necessary

7. How do you stay up-to-date on the latest taping technologies and best practices?

- Attend industry conferences and trade shows

- Read industry publications

- Network with other professionals in the field

- Take online courses or workshops

- Experiment with new techniques and technologies

8. What are your strengths and weaknesses as a Taping Supervisor?

Strengths:

- I have over 10 years of experience as a Taping Supervisor

- I am a certified Taping Supervisor

- I have a strong understanding of the taping process

- I am a highly motivated and results-oriented individual

- I am a team player and I am able to work independently

Weaknesses:

- I am not familiar with all of the latest taping technologies

- I am not always able to meet deadlines

9. Why are you interested in working as a Taping Supervisor for our company?

I am interested in working as a Taping Supervisor for your company because I am confident that I have the skills and experience that you are looking for. I am also impressed by your company’s commitment to quality and customer service. I believe that I can make a significant contribution to your team and I am eager to learn more about your company and the position.

10. What are your salary expectations?

My salary expectations are in the range of $50,000 to $60,000 per year. I am also open to discussing a salary range that is commensurate with my experience and qualifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Taping Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Taping Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Taping Supervisor plays a crucial role in ensuring the seamless operation of production lines within a manufacturing or construction setting. The key job responsibilities typically include:

1. Production Management

• Overseeing daily production targets and ensuring they are met or exceeded.

• Monitoring production line efficiency, identifying bottlenecks, and implementing improvement strategies.

• Maintaining quality standards and adherence to safety protocols throughout the production process.

2. Team Management

• Leading and motivating a team of tapers, ensuring they are well-trained, efficient, and productive.

• Providing clear instructions, setting expectations, and offering guidance to team members.

• Addressing any performance issues, providing constructive feedback, and recognizing achievements.

3. Equipment Maintenance

• Maintaining and servicing taping equipment, ensuring it is in optimal working condition.

• Identifying potential issues, coordinating repairs, and minimizing downtime.

• Ensuring compliance with safety regulations and equipment maintenance standards.

4. Material Management

• Monitoring inventory levels of taping materials, such as adhesives, tapes, and dispensers.

• Coordinating with suppliers to ensure timely delivery of materials and minimize disruptions.

• Implementing cost-effective measures to optimize material usage and reduce waste.

5. Quality Control

• Ensuring the quality of the taped products and adherence to specifications.

• Conducting regular inspections, identifying defects, and implementing corrective actions.

• Providing feedback to production teams on quality improvement areas.

Interview Tips

To ace the interview for a Taping Supervisor position, consider the following preparation tips:

1. Research the Company and Role

• Thoroughly research the company’s website, industry news, and social media presence.

• Review the job description and identify the key responsibilities and qualifications.

• Prepare specific examples of your experience and skills that align with the role’s requirements.

2. Practice Common Interview Questions

• Prepare answers to common interview questions, such as “Tell me about a time you led a team to success” or “How do you handle performance issues.”

• Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

• Practice your answers aloud to gain confidence and improve your delivery.

3. Highlight Your Leadership and Management Skills

• Emphasize your ability to lead, motivate, and develop a team of tapers.

• Provide examples of how you have successfully managed production schedules, resolved conflicts, and improved team performance.

• Showcase your understanding of team dynamics and your ability to create a positive work environment.

4. Demonstrate Your Technical Expertise

• Demonstrate your knowledge of taping equipment, materials, and quality control processes.

• Discuss your experience in maintaining and servicing taping machines and implementing preventive maintenance strategies.

• Highlight your ability to identify and resolve technical issues and ensure production efficiency.

5. Prepare Questions for the Interviewer

• Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry.

• This shows your interest, engagement, and desire to learn more about the opportunity.

• Consider questions that demonstrate your enthusiasm and commitment to the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Taping Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.