Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tapper Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tapper Helper so you can tailor your answers to impress potential employers.

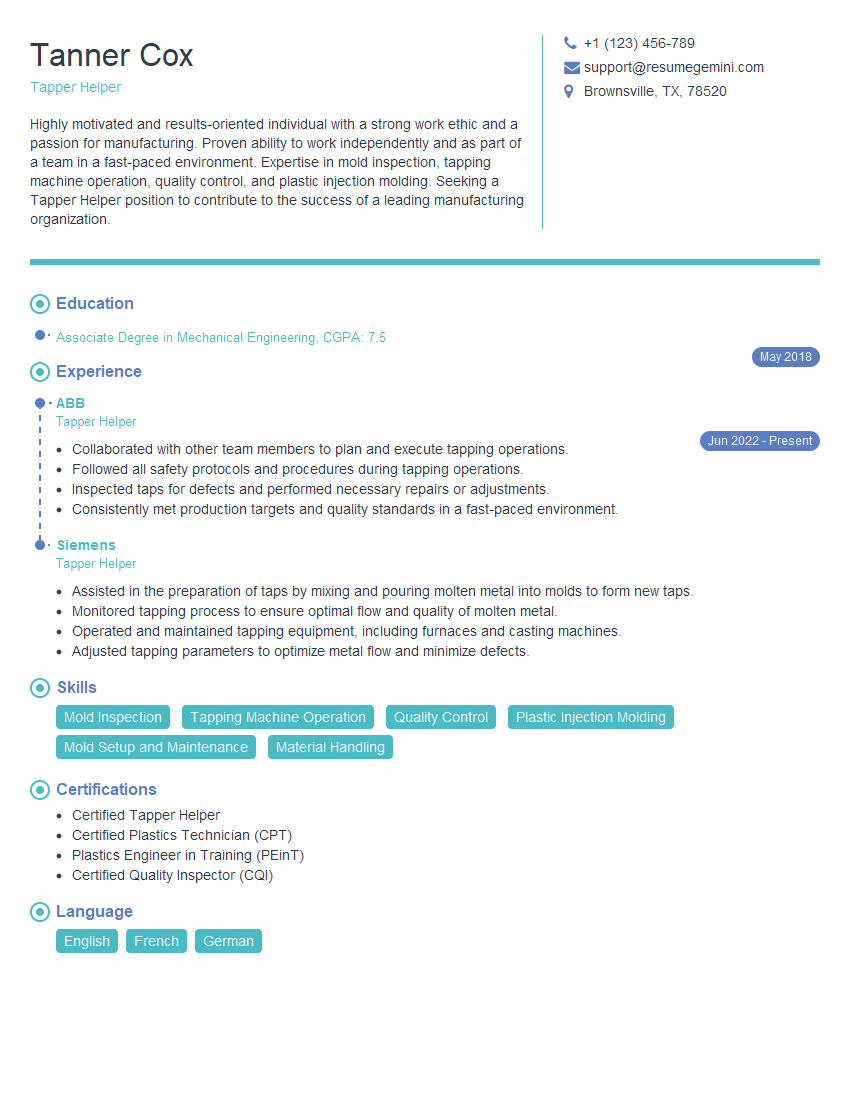

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tapper Helper

1. Explain the role of a Tapper Helper?

A Tapper Helper works under the guidance of a Tapper to assist in the production of tapped holes. The role may involve:

- Loading and unloading workpieces from the tapping machine

- Monitoring the tapping process and making adjustments as needed

- Inspecting tapped holes for quality

- Cleaning and maintaining the tapping machine and work area

2. What is the importance of following safety protocols when working as a Tapper Helper?

Safety Regulations

- Adhering to all established safety protocols is crucial to prevent accidents and injuries.

- Tapper Helpers must be aware of the hazards associated with operating tapping machines.

Maintaining a Clean Work Area

- Keeping the work area clean and free of debris helps prevent slips, trips, and falls.

- Properly disposing of scrap metal and cutting fluids ensures a safe environment.

3. How do you ensure the accuracy and precision of tapped holes?

To ensure accurate and precise tapped holes, it is essential to:

- Use the correct tap size and drill bit for the workpiece material

- Properly secure the workpiece in the tapping machine

- Apply the correct amount of cutting fluid

- Monitor the tapping process and make adjustments as needed

- Inspect the tapped holes for quality before moving on to the next workpiece

4. What are the common challenges faced by Tapper Helpers, and how do you overcome them?

Common challenges faced by Tapper Helpers include:

- Broken taps: Carefully following the manufacturer’s instructions, using sharp taps, and applying the correct amount of cutting fluid can minimize tap breakage.

- Cross-threading: Proper alignment of the tap and workpiece, using a tap guide, and taking care not to force the tap can prevent cross-threading.

- Tapping blind holes: Using a bottoming tap and carefully controlling the tapping depth can ensure proper thread formation in blind holes.

5. Describe your experience in troubleshooting common issues with tapping machines.

Troubleshooting common issues with tapping machines involves:

- Identifying the problem by observing symptoms and error messages

- Checking for loose connections, worn parts, or incorrect settings

- Consulting the machine manual or seeking guidance from a supervisor

- Performing necessary adjustments or repairs to resolve the issue

- Testing the machine to ensure it is functioning correctly before resuming operation

6. How do you maintain and clean tapping machines to ensure optimal performance?

Maintaining and cleaning tapping machines involves:

- Regularly lubricating moving parts and components

- Cleaning the machine bed, spindle, and coolant system

- Inspecting and replacing worn or damaged parts

- Calibrating the machine to ensure accuracy

- Following the manufacturer’s recommended maintenance schedule

7. What is your understanding of different types of taps, and when is each type used?

Different types of taps include:

- Straight taps: Used for through holes

- Taper taps: Used to create tapered threads

- Bottoming taps: Used to create threads that extend to the bottom of a blind hole

- Spiral taps: Used for faster tapping and chip removal

8. How do you handle high-volume tapping operations, and what techniques do you use to increase efficiency?

Handling high-volume tapping operations involves:

- Optimizing machine settings for speed and accuracy

- Using automatic feeding systems to load and unload workpieces

- Employing quick-change tapping heads to reduce downtime

- Regularly monitoring the tapping process and making adjustments as needed

9. What is your experience in using thread gauges to verify the quality of tapped holes?

Using thread gauges involves:

- Selecting the correct gauge for the thread size and pitch

- Inserting the gauge into the tapped hole and checking for proper fit

- Identifying any deviations from the specified thread dimensions

- Reporting any non-conforming holes for corrective action

10. How do you stay up-to-date with industry best practices and advancements in tapping technology?

To stay up-to-date, it is essential to:

- Attend industry conferences and workshops

- Read technical publications and articles

- Consult with manufacturers and suppliers for new product information

- Participate in online forums and discussion groups

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tapper Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tapper Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tapper Helpers are responsible for assisting in the tapping process, which involves extracting sap from trees to produce maple syrup. Their key responsibilities include:

1. Tapping trees

Drilling holes into trees and inserting spiles to allow sap to flow.

2. Collecting sap

Monitoring and collecting sap from spiles and transporting it to storage tanks.

3. Cleaning and maintaining equipment

Cleaning and sanitizing spiles, buckets, and other tapping equipment to ensure hygiene.

4. Assisting in syrup production

Assisting in filtering, boiling, and packaging maple syrup to meet quality standards.

Interview Tips

To ace an interview for a Tapper Helper position, consider the following tips:

1. Research the industry and company

Familiarize yourself with the maple syrup industry, its processes, and the company you’re applying to.

- Visit the company’s website and social media pages.

- Read articles and news about the industry.

2. Highlight your physical abilities

Emphasize your ability to perform physical tasks such as drilling holes, carrying heavy buckets, and working in outdoor conditions.

- Share previous work experience that involved physical labor.

- Mention any hobbies or activities that demonstrate your physical fitness.

3. Demonstrate your attention to detail

Stress your ability to pay close attention to detail when collecting and handling sap, cleaning equipment, and maintaining hygiene.

- Provide examples of tasks where you demonstrated accuracy and attention to detail.

- Explain how you would ensure the cleanliness and quality of the sap and syrup.

4. Show enthusiasm for the industry

Express your interest in the maple syrup industry and your desire to learn more about the process and contribute to its success.

- Share any knowledge or experience you have with maple syrup production.

- Explain why you’re passionate about working in this field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tapper Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!