Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tar Kettle Runner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

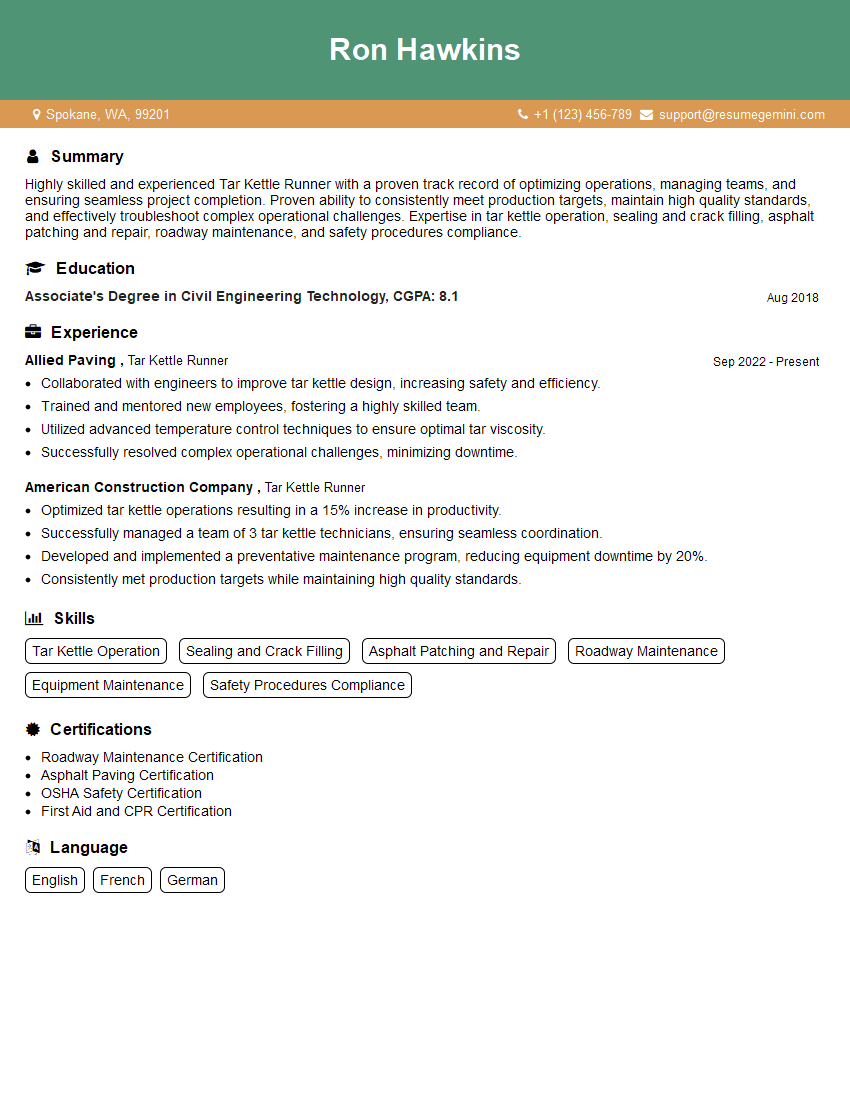

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tar Kettle Runner

1. What are the different types of tar kettles and their uses?

- Type 1: Top-loading tar kettles – These kettles have a lid that opens from the top, making it easy to add tar and other materials. They are often used for small to medium-sized jobs.

- Type 2: Side-loading tar kettles – These kettles have a door on the side that allows for easy loading and unloading of tar and other materials. They are often used for larger jobs.

- Type 3: Tilting tar kettles – These kettles can be tilted to pour tar and other materials. They are often used for jobs where it is necessary to pour tar into narrow or hard-to-reach areas.

2. How do you maintain a tar kettle?

Regular Maintenance

- Check the tar kettle for leaks or damage before each use.

- Clean the tar kettle after each use to prevent the buildup of tar and other materials.

Periodic Maintenance

- Inspect the tar kettle’s heating element and replace it if necessary.

- Inspect the tar kettle’s thermostat and replace it if necessary.

- Inspect the tar kettle’s pump and replace it if necessary.

3. What safety precautions should be taken when using a tar kettle?

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Keep the tar kettle away from flammable materials.

- Do not smoke or eat while using the tar kettle.

- Be aware of the potential for burns and take precautions to avoid them.

4. What are the different types of tar and their uses?

- Coal tar – Coal tar is a black, viscous liquid that is produced from the distillation of coal. It is used as a sealant, a waterproofing agent, and a roofing material.

- Asphalt – Asphalt is a black, sticky substance that is found in nature. It is used as a paving material, a roofing material, and a sealant.

- Pitch – Pitch is a black, solid substance that is produced from the distillation of tar. It is used as a sealant, a waterproofing agent, and a roofing material.

5. How do you apply tar?

- Heat the tar to the desired temperature.

- Apply the tar to the surface using a brush, roller, or spray gun.

- Allow the tar to cool and harden.

6. How do you remove tar?

- Use a tar remover to dissolve the tar.

- Scrape the tar off the surface using a putty knife or a scraper.

- Rinse the surface with water to remove any remaining tar.

7. What are the different types of tar kettle heaters?

- Propane heaters – Propane heaters are a popular choice for tar kettles because they are portable and easy to use. They provide a consistent heat source that is ideal for melting tar.

- Electric heaters – Electric heaters are a good choice for tar kettles that will be used in indoor applications. They are more efficient than propane heaters, but they require a power source.

- Oil-fired heaters – Oil-fired heaters are a good choice for tar kettles that will be used in outdoor applications. They are more powerful than propane heaters and electric heaters, but they require a fuel source.

8. How do you troubleshoot a tar kettle?

- If the tar kettle is not heating up, check the power source, the heating element, and the thermostat.

- If the tar kettle is overheating, check the thermostat and the heating element.

- If the tar kettle is leaking, check the seams and the gaskets.

9. What are the different types of tar kettle accessories?

- Thermometers – Thermometers are used to measure the temperature of the tar. This is important to ensure that the tar is not too hot or too cold.

- Pumps – Pumps are used to circulate the tar. This helps to prevent the tar from settling at the bottom of the kettle and burning.

- Strainers – Strainers are used to remove debris from the tar. This helps to prevent the tar from clogging the kettle.

10. What are the different applications of tar kettles?

- Road construction – Tar kettles are used to apply tar to roads. This helps to seal the road and prevent water from seeping in.

- Roofing – Tar kettles are used to apply tar to roofs. This helps to waterproof the roof and protect it from the elements.

- Waterproofing – Tar kettles are used to waterproof a variety of surfaces, such as foundations, basements, and decks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tar Kettle Runner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tar Kettle Runner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tar Kettle Runners are essential in road construction and maintenance projects, responsible for operating and maintaining tar kettles used to melt and apply tar or asphalt to surfaces.

1. Kettle Operation and Maintenance

Tar Kettle Runners are proficient in operating and maintaining tar kettles, ensuring they are in optimal condition for tar or asphalt application.

- Monitor kettle temperature, maintaining it within specified ranges for effective tar or asphalt application.

- Inspect and maintain kettle components, including burners, valves, and pumps, ensuring proper functioning.

2. Tar or Asphalt Application

They are responsible for applying tar or asphalt accurately and efficiently to road surfaces, ensuring proper bonding and sealing.

- Control the flow of tar or asphalt from the kettle, directing it precisely onto the designated areas.

- Adjust the spray nozzle to achieve the desired application thickness and coverage.

3. Equipment Transportation and Setup

Tar Kettle Runners are responsible for transporting and setting up tar kettles at designated work sites.

- Operate vehicles or equipment to transport the kettle to the worksite.

- Assemble and position the kettle, ensuring stability and proper alignment.

4. Safety and Environmental Compliance

They prioritize safety and adhere to environmental regulations while operating tar kettles.

- Wear appropriate personal protective equipment (PPE) to minimize exposure to hazardous materials.

- Follow established safety protocols and procedures for kettle operation and tar or asphalt handling.

- Dispose of waste materials and byproducts in accordance with environmental regulations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some crucial tips to help you ace your Tar Kettle Runner interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s history, values, and current projects. This will demonstrate your interest and eagerness to learn more about their operations.

2. Highlight Relevant Experience and Skills

Carefully review the job description and identify the specific skills and experience required for the role. In your resume and during the interview, emphasize your previous experience operating tar kettles or similar equipment, as well as any relevant safety certifications or training.

3. Demonstrate Safety Consciousness and Environmental Awareness

As safety and environmental compliance are paramount in this role, make it clear that you prioritize these aspects. Discuss your understanding of safety protocols, proper handling of hazardous materials, and environmental regulations.

4. Showcase Physical Ability and Stamina

Tar Kettle Runners perform physically demanding tasks. If possible, provide examples of your physical strength, endurance, and ability to withstand outdoor conditions during the interview.

5. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s projects, the role’s responsibilities, or opportunities for training and advancement.

Next Step:

Now that you’re armed with the knowledge of Tar Kettle Runner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tar Kettle Runner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini