Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tar Leveler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

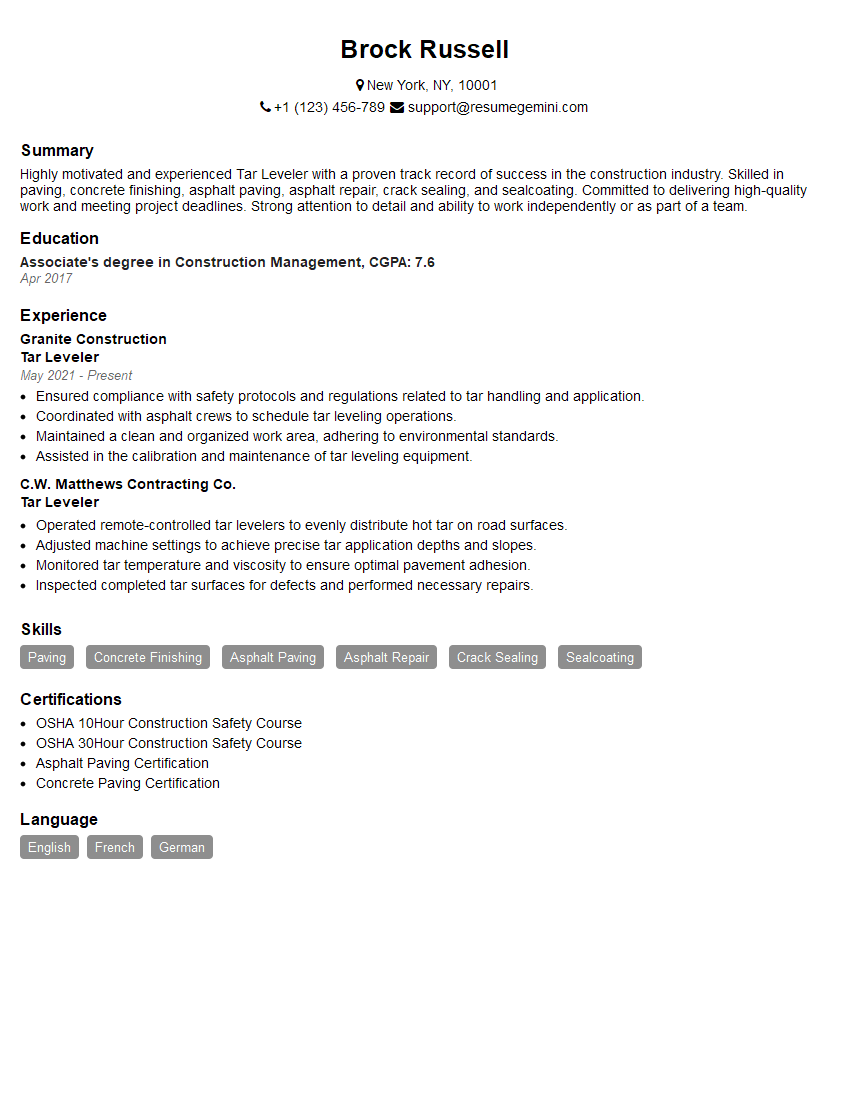

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tar Leveler

1. How do you ensure that proper compaction is achieved?

To ensure proper compaction, I meticulously follow these steps:

- Conduct Soil Testing: I perform thorough soil testing to determine its moisture content, density, and compaction requirements.

- Determine Compaction Equipment: I select the appropriate compaction equipment based on the soil type and project specifications.

- Monitor Compaction Progress: I use compaction meters or nuclear density gauges to monitor the compaction process and ensure it meets the desired density.

- Adjust Compaction Parameters: I adjust compaction parameters such as roller weight, speed, and pass coverage to optimize compaction.

- Perform Proofrolling: I conduct proofrolling to identify any soft spots or inconsistencies in the compacted surface.

2. Describe the different types of tar you have worked with and their applications.

Cold Mix Tar

- Used for patching and repair work

- Easy to apply and requires minimal equipment

Hot Mix Tar

- Used for highway construction and resurfacing

- Strong and durable

- Requires specialized equipment and heating

Asphalt Emulsions

- Used for priming and sealing surfaces

- Water-based and easy to apply

3. How do you handle potential hazards associated with tar handling and application?

I prioritize safety and handle potential hazards associated with tar by:

- Wearing Protective Gear: I wear appropriate protective gear, including respirators, gloves, and safety glasses.

- Ventilating Work Areas: I ensure adequate ventilation to prevent the accumulation of harmful fumes.

- Safe Handling Practices: I adhere to safe handling practices, such as avoiding skin contact and inhalation of fumes.

- Spill Containment: I have spill containment measures in place to prevent environmental contamination.

- Proper Disposal: I dispose of tar and related materials responsibly according to environmental regulations.

4. What techniques do you use to achieve a smooth and uniform surface finish?

To achieve a smooth and uniform surface finish, I employ the following techniques:

- Proper Screed Operation: I operate the screed smoothly and evenly to level the tar and remove any irregularities.

- Roller Techniques: I use a combination of static and vibratory rollers to compact the tar and create a smooth surface.

- Ironing: I use an iron to smooth out any bumps or depressions on the surface.

- Brooming: I broom the surface to remove any loose particles and ensure a uniform finish.

5. How do you maintain and inspect tar leveling equipment?

To maintain and inspect tar leveling equipment, I follow these practices:

- Regular Cleaning: I clean the equipment regularly to remove any tar buildup or debris.

- Lubrication: I lubricate all moving parts to ensure smooth operation.

- Inspection: I inspect the equipment before and after each use to identify any potential issues.

- Repairs and Adjustments: I promptly address any necessary repairs or adjustments to maintain optimal performance.

- Safety Checks: I conduct safety checks to ensure the equipment is operating safely.

6. Describe your experience with operating laser-guided leveling systems.

I have extensive experience operating laser-guided leveling systems for tar paving projects. These systems allow me to achieve:

- Precise Leveling: I use laser-guided leveling systems to ensure accurate leveling of the tar surface, meeting the desired grade and slope.

- Increased Productivity: Laser guidance eliminates the need for manual adjustments, saving time and increasing productivity.

- Reduced Material Waste: Precise leveling ensures optimal tar distribution, reducing material waste.

7. How do you troubleshoot common problems encountered during tar application?

I have encountered and successfully resolved various common problems during tar application, including:

- Cold Joints: I prevent cold joints by ensuring proper overlap and bonding between adjacent tar strips.

- Sagging or Buckling: I adjust compaction parameters and improve drainage to prevent sagging or buckling.

- Bleeding: I use tar with appropriate viscosity and adjust the application temperature to minimize bleeding.

- Raveling: I ensure proper compaction and use anti-raveling agents to prevent surface erosion.

8. What factors influence the choice of tar grade for a specific project?

The choice of tar grade for a specific project is influenced by several factors:

- Climate Conditions: I consider the temperature range and climate during the application and use tar grades suitable for the conditions.

- Traffic Load: I select tar grades that can withstand the expected traffic volume and weight.

- Surface Texture: I choose tar grades that provide the desired surface texture and skid resistance.

- Project Specifications: I adhere to the specific tar grade requirements outlined in project specifications.

9. How do you ensure compliance with environmental regulations during tar application?

I prioritize environmental compliance by:

- Proper Waste Disposal: I dispose of tar and related materials responsibly to prevent environmental contamination.

- Erosion Control: I implement erosion control measures to minimize sediment runoff.

- Noise and Air Quality Control: I use equipment with noise-reducing features and follow practices to minimize air pollution.

- Regular Inspections: I conduct regular inspections to identify and address any potential environmental concerns.

10. Describe your experience with managing a team of tar levelers.

As a Tar Leveler Supervisor, I have the following experience managing a team:

- Team Coordination: I effectively coordinate and assign tasks to my team to ensure efficient project execution.

- Training and Development: I provide training and support to my team to enhance their skills and knowledge.

- Performance Monitoring: I monitor team performance, provide feedback, and identify areas for improvement.

- Safety Management: I prioritize safety and ensure my team follows all safety regulations and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tar Leveler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tar Leveler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tar Leveler is a skilled laborer who works in road construction. Their primary responsibility is to use a machine called a leveler to smooth and flatten asphalt or tar surfaces on roads and other paved areas.

1. Equipment Operation

Tar Levelers are responsible for operating heavy machinery, including levelers, rollers, and pavers. They must be able to control these machines safely and efficiently.

- Operate levelers to spread and smooth asphalt or tar surfaces.

- Use rollers to compact and smooth the surface.

- Operate pavers to lay new asphalt or tar surfaces.

2. Surface Preparation

Before leveling the surface, Tar Levelers must prepare the area by removing any debris or obstacles.

- Clear the area of any debris, such as rocks, sticks, or leaves.

- Grade the surface to ensure that it is level and free of any bumps or depressions.

- Apply a tack coat to help the new asphalt or tar adhere to the existing surface.

3. Leveling and Finishing

Tar Levelers use their machines to spread and smooth the asphalt or tar surface. They must ensure that the surface is level, free of any bumps or dips, and has the correct slope for drainage.

- Spread the asphalt or tar evenly over the prepared surface.

- Smooth the surface using a leveler or roller.

- Check the surface for any imperfections and make any necessary adjustments.

4. Safety and Maintenance

Tar Levelers must follow all safety regulations and procedures when working with heavy machinery. They must also maintain their equipment to ensure that it is in good working order.

- Follow all safety regulations and procedures.

- Inspect equipment daily and make any necessary repairs.

- Clean and lubricate equipment regularly.

Interview Tips

Here are some tips to help you prepare for and ace your interview for a position as a Tar Leveler:

1. Research the Company and Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website and social media pages.

- Read news articles and press releases about the company.

- Learn about the specific position you are applying for and the responsibilities it entails.

2. Practice Your Answers

Once you have a good understanding of the company and the position, it is important to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

- Practice answering questions about your experience, skills, and qualifications.

- Be prepared to answer questions about your knowledge of the industry and the equipment you use.

- You should also practice answering questions about your safety record and your commitment to following safety regulations.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a construction environment.

- Wear long pants and a shirt with a collar.

- Wear sturdy shoes that provide good support.

- Avoid wearing clothing that is too revealing or too casual.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Plan your route to the interview in advance and leave yourself plenty of time to get there, especially if you are unfamiliar with the area.

- Check traffic conditions before you leave.

- Leave early so that you have time to find the location and park.

- If you are running late, call the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. Employers want to get to know the real you, so don’t try to be someone you’re not.

- Be honest about your experience and skills.

- Show your passion for the industry.

- Let your personality shine through.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tar Leveler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tar Leveler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.