Feeling lost in a sea of interview questions? Landed that dream interview for Tar Processing Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tar Processing Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

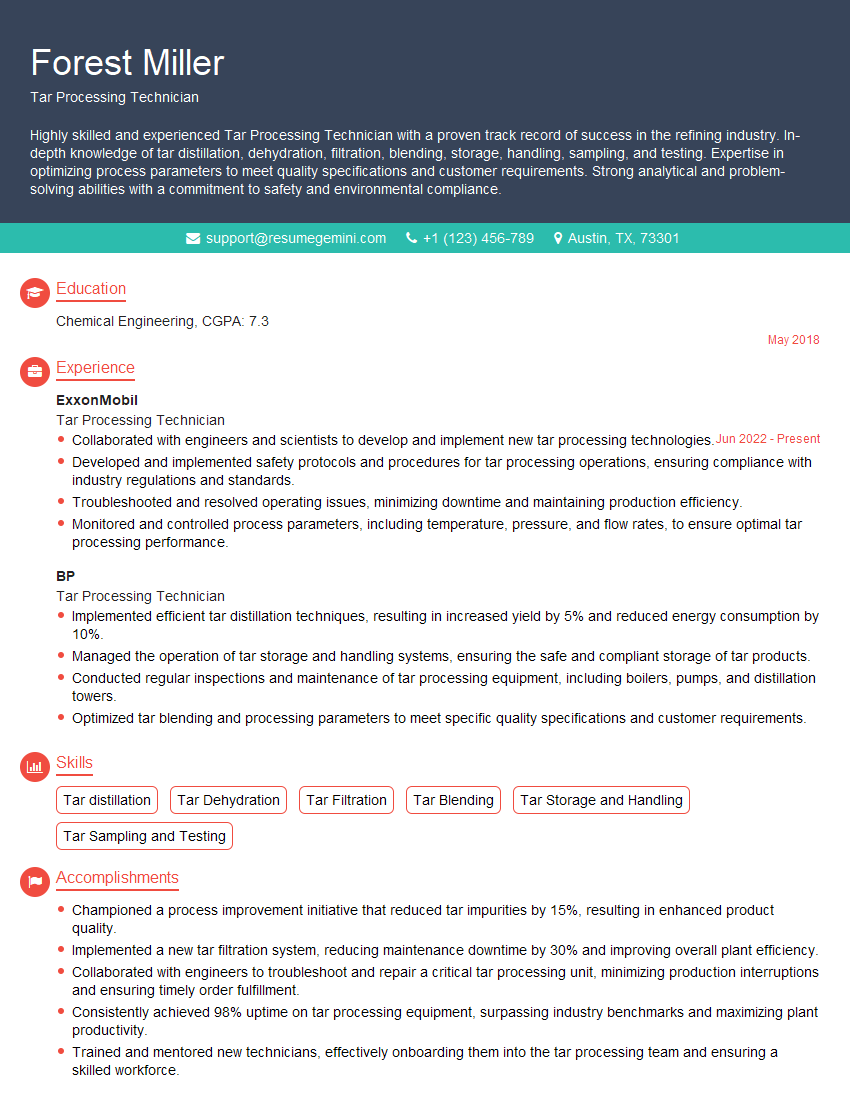

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tar Processing Technician

1. What are the key responsibilities of a Tar Processing Technician?

As a Tar Processing Technician, my key responsibilities include:

- Operating and maintaining tar processing equipment, ensuring efficient and safe production.

- Monitoring process parameters, adjusting equipment settings, and troubleshooting process deviations.

- Performing quality control tests on raw materials and finished products to ensure specification compliance.

- Adhering to safety protocols, maintaining a clean and organized work area, and following industry best practices.

- Working effectively as part of a team and communicating clearly with colleagues and supervisors.

2. Describe the process of tar distillation and its importance.

Tar Distillation Process

- The tar distillation process involves heating tar to high temperatures in a distillation column.

- As the temperature rises, different fractions of the tar vaporize and condense at specific temperatures.

- These fractions, known as distillates, have varying properties and are collected and used for various purposes.

Importance

- Tar distillation allows for the separation of valuable components from tar, such as creosote oil, pitch, and tar acids.

- These distillates are used in a wide range of applications, including wood preservation, roofing materials, and pharmaceuticals.

3. How do you ensure the quality of tar products?

I ensure the quality of tar products through a comprehensive quality control program that includes:

- Regular testing of raw materials and finished products against established specifications.

- Monitoring process parameters and making adjustments as necessary to maintain desired product quality.

- Implementing corrective actions when quality deviations are detected.

- Documenting all quality control activities and maintaining detailed records for traceability and compliance.

4. What are the common challenges faced in tar processing and how do you overcome them?

Common challenges in tar processing include:

- Equipment failures: I address these promptly by performing preventive maintenance, troubleshooting issues, and coordinating repairs or replacements.

- Process deviations: I monitor process parameters closely, make timely adjustments, and consult with supervisors to identify and resolve root causes.

- Environmental compliance: I adhere to all applicable environmental regulations, follow best practices for waste management, and work to minimize the impact of operations on the surrounding environment.

5. How do you stay up-to-date with industry best practices and technological advancements in tar processing?

I stay abreast of industry best practices and advancements through:

- Attending industry conferences, workshops, and training sessions.

- Subscribing to trade publications and technical journals.

- Networking with colleagues and industry professionals.

- Researching and exploring new technologies and innovations in the field.

6. What safety precautions are essential in a tar processing plant?

Essential safety precautions in a tar processing plant include:

- Wearing appropriate personal protective equipment (PPE), such as respirators, gloves, and protective clothing.

- Maintaining a clean and organized work area to minimize tripping hazards and spills.

- Following proper operating procedures and lockout/tagout protocols.

- Training employees on safety protocols and emergency response procedures.

- Regularly inspecting equipment and infrastructure for potential hazards.

7. How do you handle and dispose of waste products generated during tar processing?

I handle and dispose of waste products in a responsible and environmentally friendly manner, in accordance with applicable regulations:

- Segregating waste streams based on their characteristics (e.g., hazardous vs. non-hazardous).

- Storing waste materials in designated areas and ensuring proper labeling and documentation.

- Contracting with licensed waste disposal companies for safe and compliant disposal.

- Minimizing waste generation through process optimization and recycling initiatives.

8. What is the role of automation and data analysis in modern tar processing plants?

Automation and data analysis play crucial roles in modern tar processing plants:

- Automation: Automated systems improve efficiency, reduce human error, and enhance safety by automating repetitive tasks and monitoring process parameters.

- Data analysis: Collecting and analyzing process data enables operators to optimize process parameters, predict potential deviations, and improve overall plant performance.

9. How do you prioritize tasks and manage your time effectively in a fast-paced production environment?

I prioritize tasks and manage my time effectively by:

- Understanding the importance and urgency of each task.

- Creating a work plan and setting realistic deadlines.

- Delegating tasks to team members when appropriate.

- Using time management tools and techniques.

- Staying organized and keeping track of progress.

10. What motivates you to work as a Tar Processing Technician?

I am motivated to work as a Tar Processing Technician because:

- I enjoy the challenge of working in a complex and demanding environment.

- I am passionate about ensuring product quality and environmental compliance.

- I value the opportunity to contribute to the production of essential materials.

- I am eager to continuously learn and grow in the field of tar processing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tar Processing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tar Processing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tar Processing Technicians are responsible for operating and maintaining equipment used to process tar. The key job responsibilities include:

1. Operate processing equipment

Technicians operate and monitor equipment used to distil, dehydrate, and fractionate tar.

- Starting and stopping equipment

- Monitoring process parameters

- Adjusting controls as needed

2. Maintain equipment

Technicians perform routine maintenance on equipment to ensure its proper functioning.

- Cleaning and lubricating equipment

- Inspecting equipment for wear and tear

- Repairing or replacing damaged parts

3. Quality control

Technicians monitor the quality of tar produced.

- Conducting tests on tar samples

- Ensuring that tar meets specifications

- Adjusting process parameters as needed

4. Safety

Technicians follow safety procedures to ensure their own safety and the safety of others.

- Wearing appropriate personal protective equipment

- Following proper operating procedures

- Reporting any unsafe conditions

Interview Tips

Here are some tips to help you ace your interview for a Tar Processing Technician position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Tailor your answers to the job you are applying for

3. Be prepared to discuss your technical skills

As a Tar Processing Technician, you will need to have a strong understanding of the technical aspects of tar processing. Be prepared to discuss your experience in this area, including your knowledge of equipment and processes.

- Highlight your experience with distillation, dehydration, and fractionation

- Discuss your understanding of tar properties and specifications

- Explain your experience with quality control procedures

4. Emphasize your safety awareness

Safety is a critical aspect of tar processing. Be sure to emphasize your safety awareness and your commitment to following safety procedures.

- Explain your experience with wearing PPE

- Discuss your understanding of proper operating procedures

- Explain how you would respond to a safety incident

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tar Processing Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.