Are you gearing up for a career in Technical Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Technical Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

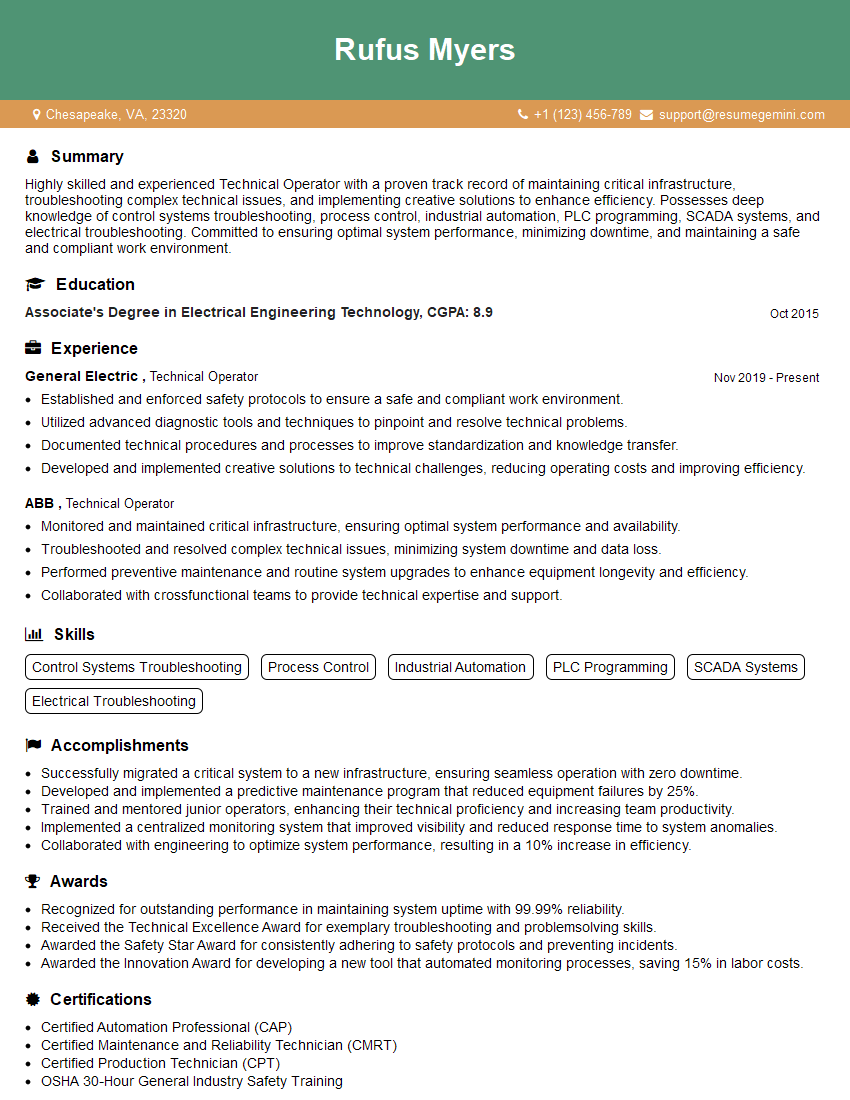

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Technical Operator

1. Describe your understanding of the role and responsibilities of a Technical Operator?

As a Technical Operator, I possess a comprehensive understanding of the role’s key responsibilities, including:

- Monitoring and controlling technical systems

- Troubleshooting and resolving technical issues

- Performing routine maintenance and repairs

- Responding to emergencies and ensuring safety

- Adhering to safety protocols and regulations

2. Can you explain the concepts of PLC (Programmable Logic Controller) and its applications in industrial automation?

PLC Fundamentals

- Input/output processing device

- Stores and executes control programs

- Communicates with sensors, actuators, and other devices

Applications in Industrial Automation

- Control of production lines

- Monitoring of equipment and processes

- Data acquisition and analysis

- Safety interlocking

3. How do you approach troubleshooting electrical systems in a manufacturing environment?

My troubleshooting approach involves a systematic and logical process:

- Identify the symptoms and gather information

- Inspect the system for potential causes

- Use testing equipment to isolate the fault

- Analyze the data and determine the root cause

- Implement repairs or adjustments to resolve the issue

- Verify the system functionality and ensure safety

4. What are the essential safety protocols you adhere to in a technical operations environment?

- Lockout/tagout procedures

- Electrical safety guidelines

- Hazard identification and risk assessment

- Emergency response protocols

- Personal protective equipment (PPE) requirements

5. Explain the importance of preventive maintenance in ensuring the reliability of industrial equipment.

- Reduces unplanned downtime and maintenance costs

- Extends equipment lifespan and improves performance

- Enhances safety by identifying potential hazards early

- Optimizes production efficiency and quality

- Facilitates regulatory compliance and industry standards

6. How do you ensure the accuracy and efficiency of data collection and reporting in a technical operations environment?

- Establish clear data collection methods and protocols

- Use appropriate monitoring and recording tools

- Validate data accuracy through verification and cross-checking

- Analyze data to identify trends and improvement areas

- Generate comprehensive reports to communicate findings

7. What software applications or programming languages are you familiar with in your technical operations role?

- SCADA (Supervisory Control and Data Acquisition) systems

- PLC programming languages (e.g., Ladder Logic, Structured Text)

- Data analysis and visualization software

- Maintenance management systems

- Computer-aided design (CAD) software

8. How do you stay up-to-date with advancements in technology and industry best practices?

- Attend industry conferences and webinars

- Subscribe to technical publications and journals

- Participate in training and development programs

- Network with peers and experts in the field

- Conduct research and explore emerging technologies

9. Describe a challenging technical project you successfully completed in your previous role.

In my previous role, I was involved in the installation and commissioning of a new production line. The project involved:

- PLC programming and system integration

- Electrical wiring and troubleshooting

- Equipment calibration and optimization

- Training of operators and maintenance personnel

- Successful implementation and increased production efficiency

10. How do you prioritize multiple tasks and manage your workload effectively in a fast-paced environment?

- Establish clear priorities based on urgency and importance

- Use task management tools and techniques (e.g., Kanban boards)

- Delegate tasks to capable team members

- Communicate effectively with colleagues and supervisors

- Remain organized and focused on achieving goals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Technical Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Technical Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Technical Operators are responsible for the day-to-day operations and maintenance of technical equipment and systems. They play a crucial role in ensuring the smooth functioning of various industries, such as manufacturing, healthcare, and transportation. Here are some key job responsibilities of a Technical Operator:

1. Equipment Operation

Operating and monitoring technical equipment according to established procedures and specifications.

- Following standard operating procedures (SOPs) for equipment usage.

- Monitoring equipment performance and making necessary adjustments to ensure optimal operation.

2. Equipment Maintenance

Performing routine maintenance and repairs to keep equipment in good working condition.

- Conducting regular inspections and identifying potential issues.

- Performing preventive maintenance tasks to prevent breakdowns and extend equipment life.

3. Troubleshooting and Problem Solving

Diagnosing and resolving equipment malfunctions and technical issues.

- Analyzing symptoms and identifying the root cause of problems.

- Implementing appropriate solutions to restore equipment functionality.

4. Data Collection and Analysis

Collecting and analyzing data from equipment and systems to identify trends and improve operations.

- Monitoring and recording equipment data such as performance metrics and fault logs.

- Using data analysis tools to identify areas for improvement and optimize processes.

5. Compliance and Safety

Ensuring compliance with safety regulations and industry standards.

- Adhering to established safety protocols and using personal protective equipment (PPE).

- Maintaining a clean and organized work environment to prevent accidents.

Interview Tips

To prepare for a Technical Operator interview, it is essential to understand the job responsibilities and highlight your relevant skills and experience. Here are some interview preparation tips and hacks:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services. Research the specific role and its responsibilities to demonstrate your understanding of the position.

- Visit the company’s website and LinkedIn page.

- Read industry publications and articles related to the company’s field.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining technical equipment. Quantify your experience with specific examples, such as reducing downtime or improving equipment efficiency.

- Showcase your knowledge of different types of equipment and systems.

- Mention any certifications or training programs you have completed.

3. Demonstrate Your Problem-Solving Abilities

Technical Operators are often tasked with troubleshooting and resolving equipment issues. Highlight your logical thinking and problem-solving skills through real-life examples.

- Describe a situation where you identified and resolved a complex technical problem.

- Emphasize your ability to analyze data and identify root causes.

4. Focus on Safety and Compliance

Safety is paramount in technical operations. Demonstrate your commitment to following safety protocols and maintaining a safe work environment.

- Discuss your experience with safety regulations and industry standards.

- Highlight your ability to identify and mitigate potential safety hazards.

5. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer shows your engagement and interest in the position. Ask questions about the company’s culture, growth opportunities, and the specific challenges of the role.

- Inquire about the company’s investment in employee training and development.

- Ask about the company’s approach to innovation and continuous improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Technical Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!