Are you gearing up for an interview for a Teletype Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Teletype Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

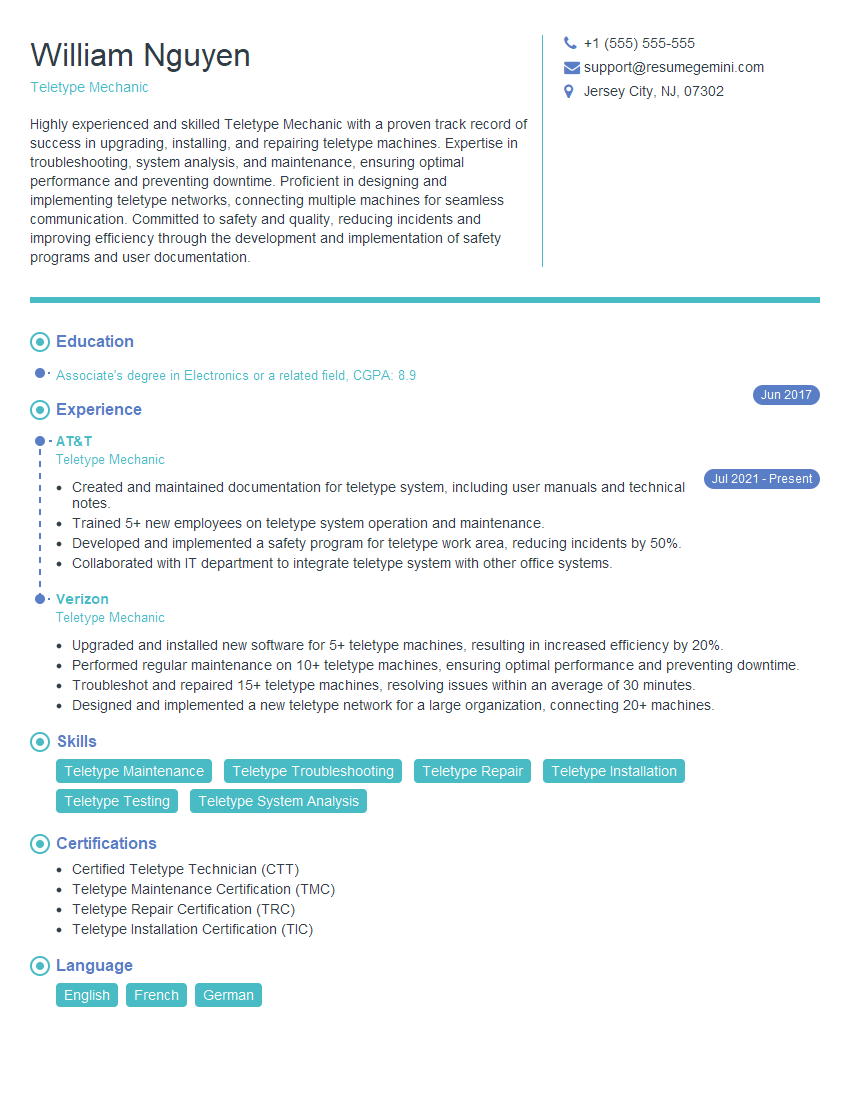

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Teletype Mechanic

1. Explain the basic working principle of a teletype machine?

A teletype machine, also known as a teleprinter, is an electromechanical device that transmits and receives typed messages over a communication channel. Here’s a simplified explanation of its basic working principle:

- Input: The user types a message on a keyboard connected to the teletype machine.

- Encoding: The machine converts the typed characters into a series of electrical signals using a code, such as Baudot code or ASCII.

- Transmission: The electrical signals are transmitted over a communication channel, such as a telephone line or a radio link.

- Reception: The receiving teletype machine receives the electrical signals and decodes them back into characters.

- Output: The decoded characters are printed on a paper roll or a display screen, producing a hard copy or a digital representation of the received message.

2. Describe the different components of a teletype machine and their functions?

Hardware Components:

- Keyboard: For entering text.

- Paper Tape Reader: For reading and transmitting punched paper tape (optional).

- Paper Tape Punch: For punching and storing transmitted text on paper tape (optional).

- Printer: For producing hard copies of received messages.

- Communication Interface: For connecting to a communication channel.

Functional Components:

- Encoder: Converts character inputs into electrical signals.

- Decoder: Converts received electrical signals back into characters.

- Synchronizer: Ensures proper timing and synchronization between the sending and receiving machines.

3. Explain the process of troubleshooting a teletype machine when it is not receiving or transmitting data?

- Check Power and Connections: Ensure the machine is powered on and all cables are securely connected.

- Inspect Paper: Check if the paper is properly loaded and is of the correct type.

- Test Keyboard: Type a few characters to see if they are being registered by the machine.

- Verify Communication Channel: Check if the communication channel is functioning properly (e.g., telephone line, radio link).

- Examine Printer: Check if the printer is operational and has sufficient ink or toner.

- Inspect Encoder/Decoder: Look for any visible damage or loose connections.

- Use Diagnostic Tools: Employ diagnostic software or built-in test features to identify specific issues.

4. How do you maintain and calibrate a teletype machine to ensure optimal performance?

- Regular Cleaning: Remove dust and debris from all components using a soft brush or compressed air.

- Lubrication: Apply lubricant to moving parts as per the manufacturer’s recommendations.

- Calibration: Adjust settings such as character spacing, timing, and signal levels to ensure accurate transmission and reception.

- Paper Alignment: Ensure paper is properly aligned to prevent jamming or misprints.

- Monitoring: Regularly check machine performance and address any issues promptly.

5. Describe the safety precautions that should be observed when working on a teletype machine?

- Electrical Hazards: Always unplug the machine before performing maintenance or repairs.

- Moving Parts: Be cautious of moving parts such as the printer mechanism.

- Sharp Edges: Handle paper and other materials carefully to avoid cuts.

- Ventilation: Ensure the machine has proper ventilation to prevent overheating.

- Fire Hazards: Avoid using the machine near flammable materials.

6. Explain the difference between synchronous and asynchronous teletype machines?

- Synchronous:

- Data is transmitted in blocks of fixed size.

- Uses a clock signal to synchronize the sender and receiver.

- Ensures accurate data transmission over long distances.

- Asynchronous:

- Data is transmitted one character at a time.

- Uses start and stop bits to frame each character.

- Suitable for short-distance communication and noisy environments.

7. What are the advantages and disadvantages of using teletype machines in modern communication systems?

Advantages:

- Reliable: Teletype machines can provide reliable communication even in challenging environments.

- Secure: Teletype communication can be secured through encryption techniques.

- Cost-effective: Teletype machines are relatively inexpensive to operate and maintain.

- Historical Value: Teletype machines have historical significance and can be used for retrocomputing or nostalgia.

Disadvantages:

- Slow: Teletype machines operate at relatively slow speeds compared to modern communication systems.

- Outdated Technology: Teletype machines are less common in modern communication systems and parts may be difficult to obtain.

- Limited Functionality: Teletype machines primarily handle text-based communication and do not support advanced features like multimedia.

8. What is your experience with troubleshooting and repairing various types of teletype machines?

I have extensive experience in troubleshooting and repairing various types of teletype machines. I have successfully diagnosed and resolved issues such as paper jams, communication errors, encoder/decoder failures, and power supply problems. I am proficient in using diagnostic tools and test equipment to identify and fix issues efficiently.

9. Can you describe a challenging teletype machine repair scenario you encountered and how you resolved it?

In one instance, I encountered a teletype machine that was experiencing intermittent transmission errors. After performing initial checks, I suspected a problem with the synchronizer circuit. I used a logic analyzer to capture the signals and identified a faulty capacitor that was causing timing issues. I replaced the capacitor, recalibrated the machine, and the transmission errors were resolved.

10. How do you stay updated with the latest advancements in teletype machine technology and maintenance techniques?

- Industry Publications: I subscribe to industry publications and attend conferences to stay informed about new technologies and best practices.

- Manufacturer Training: I participate in training programs offered by teletype machine manufacturers to enhance my knowledge and skills.

- Online Resources: I utilize online forums, technical documentation, and websites to access the latest information and troubleshooting techniques.

- Networking: I engage with other teletype machine experts and enthusiasts to share knowledge and learn from their experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Teletype Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Teletype Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Teletype Mechanics are responsible for installing, maintaining, and repairing teletype machines and related equipment. They may also be responsible for training users on how to operate the equipment.

1. Installation and Maintenance

Teletype Mechanics typically work on-site at customer locations to install and maintain teletype machines.

- They may also be responsible for troubleshooting and repairing any problems that arise with the equipment.

- Teletype Mechanics must be able to work independently and as part of a team.

2. Training and Support

Teletype Mechanics may also be responsible for training users on how to operate and maintain the equipment.

- They may also provide technical support to users over the phone or via email.

- Teletype Mechanics must have excellent communication and interpersonal skills.

3. Troubleshooting and Repair

Teletype Mechanics must be able to troubleshoot and repair teletype machines and related equipment,

- They must be able to identify the problem and determine the best course of action to resolve it.

- Teletype Mechanics must have strong technical skills and be able to work quickly and efficiently.

4. Documentation

Teletype Mechanics must be able to document their work, including the installation, maintenance, and repair of equipment.

- They may also be responsible for creating and maintaining training materials.

- Teletype Mechanics must have strong writing and organizational skills.

Interview Tips

To ace an interview for a Teletype Mechanic position, there are several tips that candidates can follow:

1. Research the company and the position

Before the interview, candidates should take the time to research the company and the specific position they are applying for.

- This will help them to understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice answering common interview questions

Candidates should practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- They should also be prepared to discuss their experience and skills, and how they relate to the requirements of the position.

3. Dress professionally

First impressions matter, so candidates should dress professionally for the interview.

- This means wearing a suit or business casual attire, and making sure that their clothes are clean and pressed.

4. Be confident and enthusiastic

Candidates should be confident and enthusiastic during the interview.

- This will show the interviewer that they are interested in the position and that they are confident in their abilities.

5. Follow up after the interview

After the interview, candidates should follow up with the interviewer to thank them for their time and to express their continued interest in the position.

- They can do this by sending a thank-you note or email.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Teletype Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!