Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Temperature Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

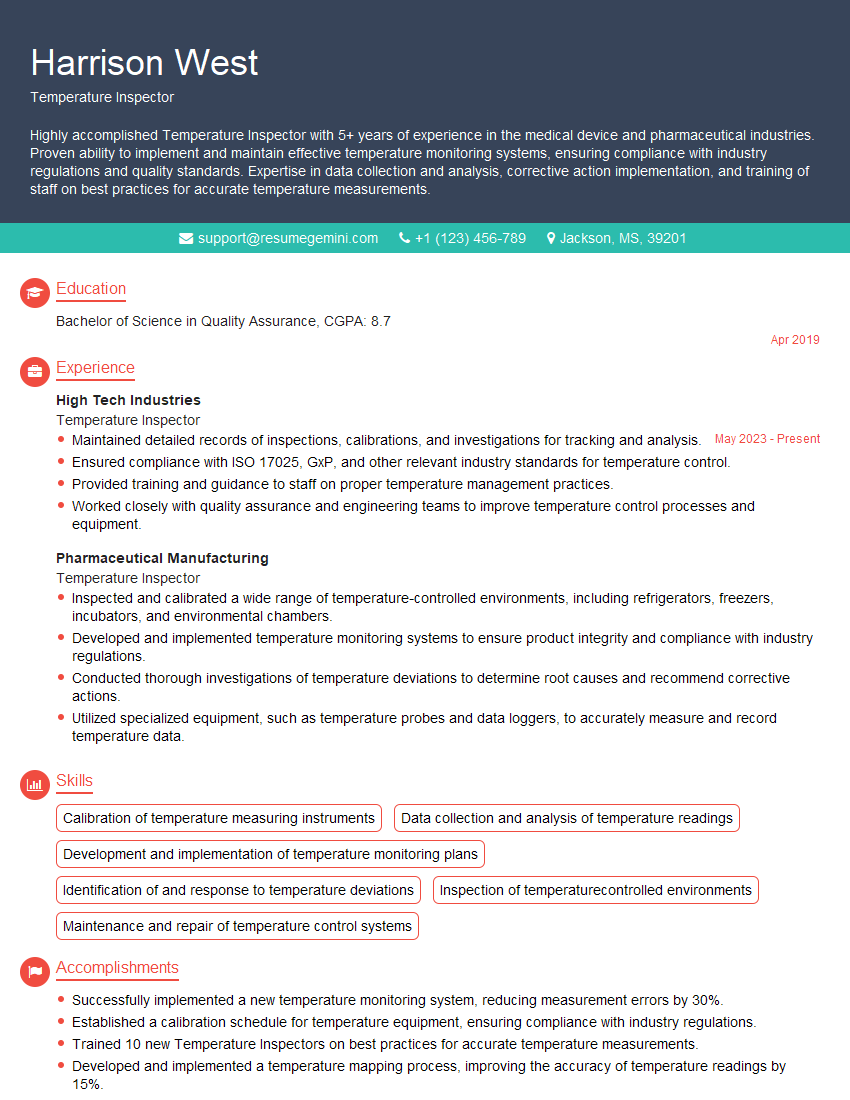

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Temperature Inspector

1. What is the difference between accuracy and precision in temperature measurement?

Accuracy refers to the closeness of a measurement to its true value, while precision refers to the closeness of repeated measurements to each other.

- Accuracy is determined by systematic errors, which are constant and can be corrected, while precision is determined by random errors, which are variable and cannot be corrected.

- High accuracy requires both high precision and low systematic error, while high precision does not necessarily imply high accuracy.

2. What are the different types of temperature sensors?

Thermocouples

- Generate an electrical signal proportional to the temperature difference between two different metals.

- Wide temperature range, high accuracy, but susceptible to noise.

Resistance Temperature Detectors (RTDs)

- Measure temperature by sensing the change in electrical resistance of a metal conductor.

- Stable, accurate, and reliable, but have a narrower temperature range than thermocouples.

Thermistors

- Semiconductor devices whose resistance changes significantly with temperature.

- Very sensitive, but have a non-linear output and limited temperature range.

3. What are the factors that affect the accuracy of a temperature measurement?

- Calibration of the sensor

- Sensor placement and thermal contact

- Ambient temperature and thermal gradients

- Signal conditioning and data acquisition

- Operator training and experience

4. How do you calibrate a temperature sensor?

- Use a reference temperature source, such as a precision thermometer or temperature bath.

- Compare the output of the sensor to the reference temperature at multiple points within the operating range.

- Adjust the sensor’s output using calibration software or hardware to match the reference temperature.

5. What are the different methods used to measure temperature in industrial processes?

- Contact measurement (thermocouples, RTDs)

- Non-contact measurement (infrared thermometers, pyrometers)

- Immersion measurement (thermocouples, RTDs)

- Surface measurement (thermocouples, RTDs, infrared thermometers)

6. What are the safety precautions to consider when measuring temperature in hazardous environments?

- Use intrinsically safe equipment

- Wear appropriate personal protective equipment (PPE)

- Follow established safety protocols

- Be aware of potential hazards, such as electrical shock, explosions, and toxic fumes

7. What are the applications of temperature measurement in industrial processes?

- Temperature control and regulation

- Process monitoring and optimization

- Quality control and product testing

- Energy management and efficiency

- Safety and environmental monitoring

8. What are the challenges of measuring temperature in extreme environments?

- Wide temperature ranges

- Harsh conditions (e.g., high pressure, vibration, corrosive gases)

- Limited access to measurement points

- Electromagnetic interference

- Safety considerations

9. How do you ensure the reliability of temperature measurements in critical applications?

- Use high-quality sensors and instruments

- Regularly calibrate and maintain equipment

- Implement redundancy and fault detection mechanisms

- Follow established quality assurance procedures

- Train operators on the importance of accurate temperature measurement

10. What is your experience with temperature measurement instrumentation?

- Types of sensors and instruments used

- Applications and industries where temperature measurement was performed

- Skills in calibration, maintenance, and troubleshooting

- Experience with data acquisition and analysis

- Knowledge of relevant standards and regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Temperature Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Temperature Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Temperature Inspector is responsible for ensuring that products and environments are maintained at the correct temperature. This role is crucial in various industries, including food and beverage, pharmaceutical, and manufacturing, where temperature control is vital for product quality and safety.

1. Temperature Monitoring and Recording

The primary responsibility of a Temperature Inspector is to monitor and record temperatures using specialized equipment such as thermometers, temperature probes, and data loggers.

- Conduct regular temperature checks on products, equipment, and storage areas.

- Maintain accurate and detailed temperature records for compliance purposes.

2. Temperature Control and Calibration

Temperature Inspectors ensure that temperatures are maintained within specified limits by adjusting and calibrating temperature-controlled equipment and systems.

- Calibrate and verify the accuracy of temperature-measuring devices.

- Adjust and repair temperature control systems to maintain optimal temperatures.

3. HACCP and GMP Compliance

In industries such as food and beverage, Temperature Inspectors play a crucial role in ensuring compliance with HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices) regulations.

- Monitor and maintain temperatures at critical control points in the production and handling process.

- Implement and supervise temperature control programs to meet regulatory standards.

4. Quality Assurance and Control

Temperature Inspectors contribute to product quality assurance by ensuring that products are stored and transported at the correct temperatures.

- Inspect and approve products based on temperature compliance.

- Identify and investigate temperature-related product defects or issues.

Interview Tips

To ace the interview for a Temperature Inspector position, it’s important to prepare thoroughly and present yourself as a knowledgeable and qualified candidate.

1. Research the Company and Industry

Before the interview, take the time to research the company and the specific industry they operate in. This will help you understand their business goals, temperature control requirements, and the regulatory environment applicable to their operations.

- Visit the company’s website and social media pages to gather information about their products, services, and values.

- Look up industry-specific news, articles, and regulations to demonstrate your understanding of the field.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in temperature monitoring, control, and calibration. Provide specific examples of how you have applied these skills in previous roles.

- Describe your experience with different temperature-measuring devices and calibration techniques.

- Showcase your ability to troubleshoot and resolve temperature-related issues in a timely and efficient manner.

3. Demonstrate Your Knowledge of HACCP and GMP

If the position involves compliance with HACCP or GMP regulations, highlight your knowledge and experience in these areas.

- Explain how you have implemented and supervised temperature control programs in previous roles.

- Provide examples of how you have identified and addressed temperature-related hazards in the production process.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to temperature control, quality assurance, and your technical abilities.

- Tell me about your experience in monitoring and recording temperatures in a production environment.

- How do you ensure the accuracy and reliability of your temperature-measuring devices?

- Describe a situation where you faced a temperature-related issue and how you resolved it.

5. Ask Informed Questions

During the interview, don’t hesitate to ask informed questions about the role, the company’s temperature control practices, and any specific challenges they may be facing.

- What are the specific temperature requirements for the products or processes you handle?

- What temperature-control systems and devices do you currently use?

- What are your expectations for the role of a Temperature Inspector in this position?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Temperature Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!