Are you gearing up for an interview for a Temperer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Temperer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

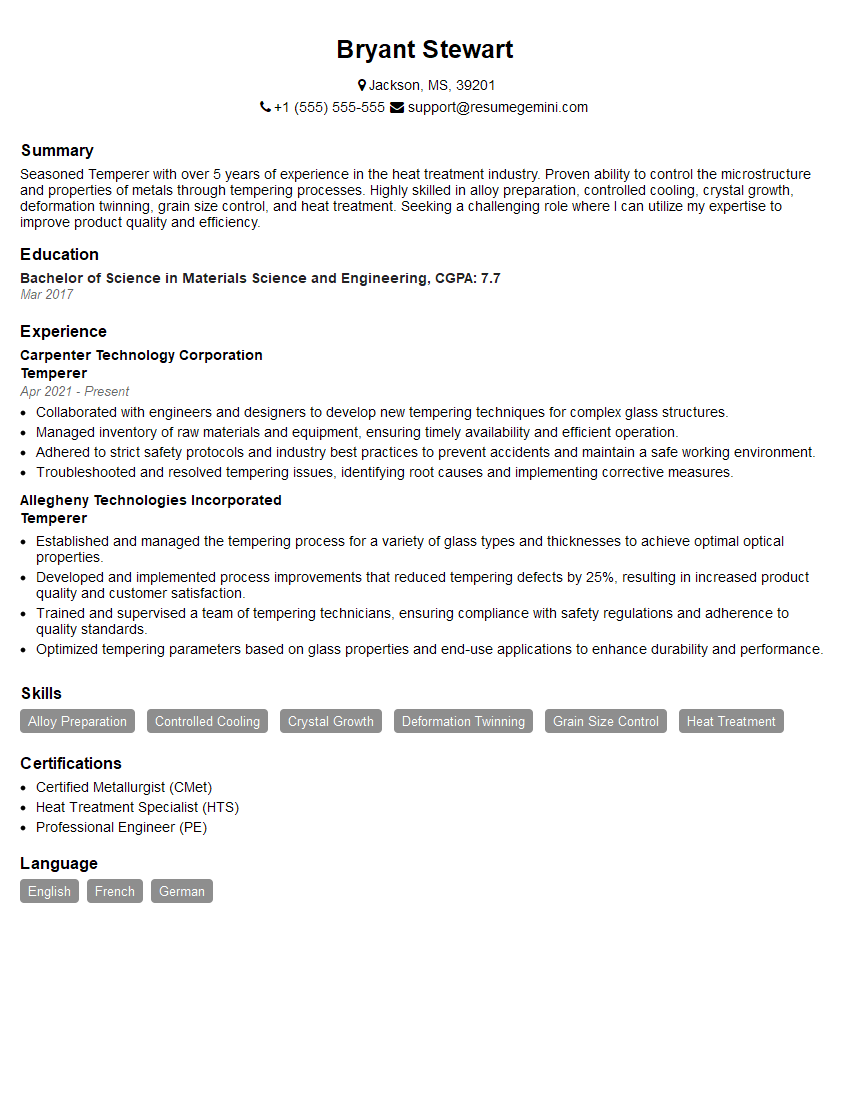

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Temperer

1. What are the different types of tempering processes?

- Subzero tempering: involves cooling steel to extremely low temperatures (-150 degrees Celsius or lower) and then tempering it to increase hardness and wear resistance.

- Water tempering: involves quenching steel in water, which is a fast cooling medium that produces a hard and brittle structure.

- Oil tempering: involves quenching steel in oil, which is a less severe cooling medium that produces a tougher and more ductile structure.

- Air tempering: involves cooling steel in air, which is a slow cooling medium that produces a softer and more flexible structure.

2. What are the factors that affect the outcome of a tempering process?

Metallurgical factors

- Steel composition

- Grain size

- Microstructure

Process factors

- Tempering temperature

- Cooling rate

- Holding time

Equipment factors

- Furnace uniformity

- Thermocouple accuracy

- Atmosphere control

3. How do you determine the optimal tempering temperature and holding time for a particular steel?

- Refer to steel data sheets: Manufacturers provide recommended tempering parameters based on the steel’s composition and intended application.

- Conduct experiments: Perform small-scale tempering trials to determine the optimal parameters for a specific steel and application.

- Use empirical relationships: Utilize established formulas and charts to estimate tempering parameters based on factors such as steel hardness and desired toughness.

4. What are the common defects associated with tempering?

- Over-tempering: Occurs when steel is tempered at too high a temperature or for too long, resulting in reduced hardness and strength.

- Under-tempering: Occurs when steel is tempered at too low a temperature or for too short a time, resulting in insufficient softening and potential brittleness.

- Embrittlement: Can occur due to improper tempering techniques, leading to reduced ductility and increased susceptibility to cracking.

- Warpage: Can occur if the steel is not properly supported during tempering, resulting in distortion or bending.

5. How do you ensure the quality of tempered parts?

- Establish and maintain process controls: Implement clear procedures and specifications for tempering processes.

- Use calibrated equipment: Ensure furnaces, thermocouples, and other equipment are properly calibrated and maintained.

- Monitor process parameters: Regularly track and record tempering temperatures, cooling rates, and holding times.

- Perform hardness testing: Conduct hardness tests on tempered parts to verify that they meet specifications.

- Inspect for defects: Visually inspect tempered parts for any signs of defects, such as cracks, warpage, or discoloration.

6. What are the latest trends in tempering technology?

- Advanced control systems: Use of computer-controlled systems to precisely manage tempering parameters and ensure consistent results.

- Rapid heating and cooling: Technologies such as induction heating and vacuum quenching to reduce processing time and improve efficiency.

- Vacuum tempering: Controlled atmosphere tempering to prevent oxidation and decarburization, resulting in superior mechanical properties.

- Laser tempering: Selective tempering of specific areas of parts using laser technology, enabling localized control of properties.

7. Describe the role of tempering in the manufacturing of specific components, such as automotive gears or surgical instruments.

Automotive gears

- Improves wear resistance and durability of gears

- Ensures gears can withstand high loads and stresses

- Reduces noise and vibration during operation

Surgical instruments

- Enhances strength and toughness of instruments

- Improves corrosion resistance and prevents pitting

- Ensures instruments can be repeatedly sterilized without losing properties

8. Explain the differences between tempering and annealing.

- Purpose: Tempering focuses on improving the mechanical properties of steel, while annealing primarily aims to soften and reduce residual stresses.

- Temperature range: Tempering is typically performed at lower temperatures (200-650 degrees Celsius), while annealing involves heating steel to higher temperatures (above the transformation temperature).

- Cooling rate: Tempering requires controlled cooling rates, whereas annealing often involves slow cooling or even air cooling.

- Resulting properties: Tempering produces a harder and stronger steel, while annealing results in a softer and more ductile steel.

9. Discuss the importance of proper quality control in tempering processes.

- Ensures consistent product quality: Proper quality control helps maintain specified mechanical properties and performance of tempered parts.

- Prevents defects and failures: Identifies and mitigates potential defects, such as over-tempering or under-tempering, which could compromise part integrity.

- Reduces production costs: Minimizes the risk of producing defective parts, which can lead to costly rework, scrap, and warranty claims.

- Improves customer satisfaction: Delivers reliable and high-quality tempered parts that meet customer expectations.

10. How do you stay updated with advancements in tempering technology?

- Attend industry conferences and seminars: Network with experts and learn about the latest developments.

- Read technical journals and publications: Stay informed about new research and innovations in tempering.

- Collaborate with equipment manufacturers and suppliers: Explore emerging technologies and discuss potential applications.

- Participate in online forums and discussion groups: Engage with industry professionals and share knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Temperer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Temperer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Temperer plays a vital role in the manufacturing industry by maintaining and calibrating temperature control equipment. Their primary responsibilities encompass:1. Equipment Maintenance and Calibration

The Temperer is responsible for ensuring the accuracy and efficiency of temperature control equipment. This involves:

- Conducting regular maintenance and inspections to prevent breakdowns and ensure optimal performance.

- Calibrating temperature sensors, controllers, and actuators to guarantee precise temperature readings.

- Troubleshooting and repairing equipment malfunctions to minimize downtime and maintain productivity.

2. Process Optimization

To enhance the efficiency of temperature control systems, the Temperer performs the following tasks:

- Monitoring process variables, such as temperature, pressure, and flow rates, to identify areas for improvement.

- Evaluating and implementing process modifications to reduce energy consumption and optimize production output.

- Collaborating with engineers and operators to develop and implement temperature control strategies that meet specific process requirements.

3. Data Analysis and Reporting

The Temperer collects and analyzes data related to temperature control systems to ensure accurate reporting and decision-making:

- Documenting and maintaining records of equipment performance, calibrations, and maintenance activities.

- Analyzing data to identify trends, patterns, and areas for further optimization.

- Preparing reports and presentations on temperature control system performance and recommendations for improvement.

4. Compliance and Safety

The Temperer adheres to industry standards and regulations to ensure compliance and safety:

- Enforcing safety protocols and procedures related to temperature control equipment operation.

- Participating in safety training programs to stay updated with industry best practices.

- Ensuring that temperature control systems meet regulatory requirements and industry standards.

Interview Preparation Tips

To excel in an interview for a Temperer position, candidates should consider the following preparation tips:1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and culture. Research the specific responsibilities of a Temperer in this organization to align your qualifications with the job requirements.

2. Highlight Your Experience and Skills

Emphasize your relevant work experience in temperature control equipment maintenance, calibration, and process optimization. Quantify your accomplishments using specific metrics to demonstrate your impact.

3. Demonstrate Your Technical Knowledge

Be prepared to discuss your understanding of temperature control principles, equipment types, and calibration techniques. Provide examples of projects where you have successfully applied your technical skills.

4. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve equipment issues. Highlight situations where you identified and solved technical problems effectively.

5. Prepare for Behavioral Questions

Expect behavioral questions that assess your teamwork, communication, and customer service skills. Prepare examples of how you have successfully collaborated with others and provided excellent customer support.

6. Ask Thoughtful Questions

Asking well-thought-out questions shows your engagement and interest in the position. Prepare questions about the company’s temperature control initiatives, industry trends, or any specific challenges you may have identified during your research.

7. Practice Your Answers

Rehearse your answers to common interview questions to build confidence and deliver clear and concise responses.

8. Dress Professionally and Arrive On Time

First impressions matter. Dress professionally and arrive on time for your interview. Punctuality and a polished appearance convey respect and seriousness about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Temperer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.